Holographic information layer, anti-counterfeiting film and identification assembly

A technology of holographic information and anti-counterfeiting film, applied in the field of anti-counterfeiting printing, can solve problems such as short lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

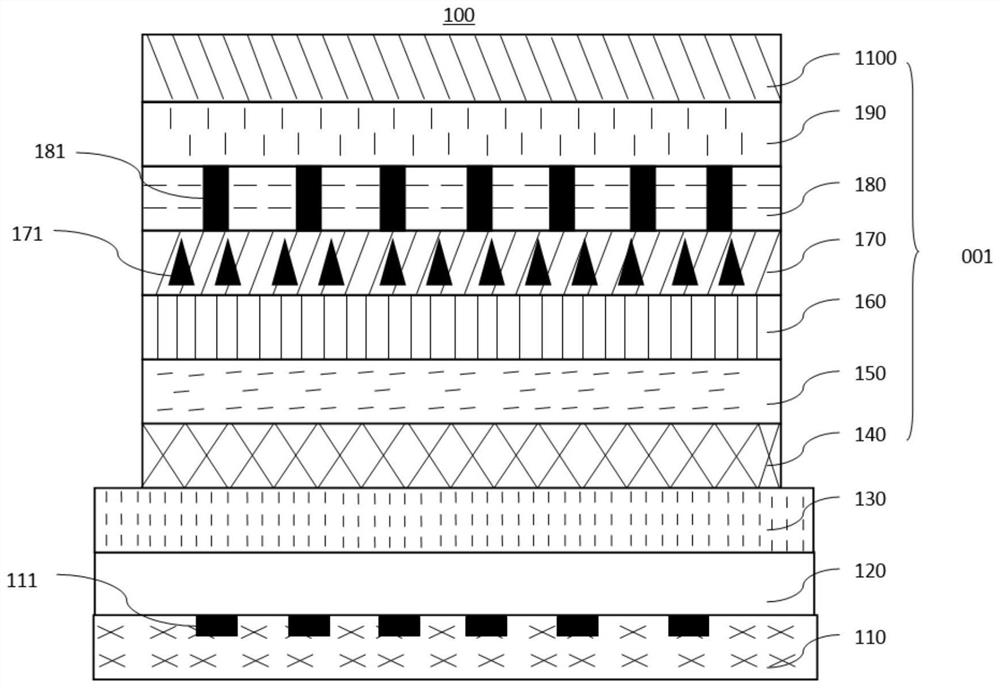

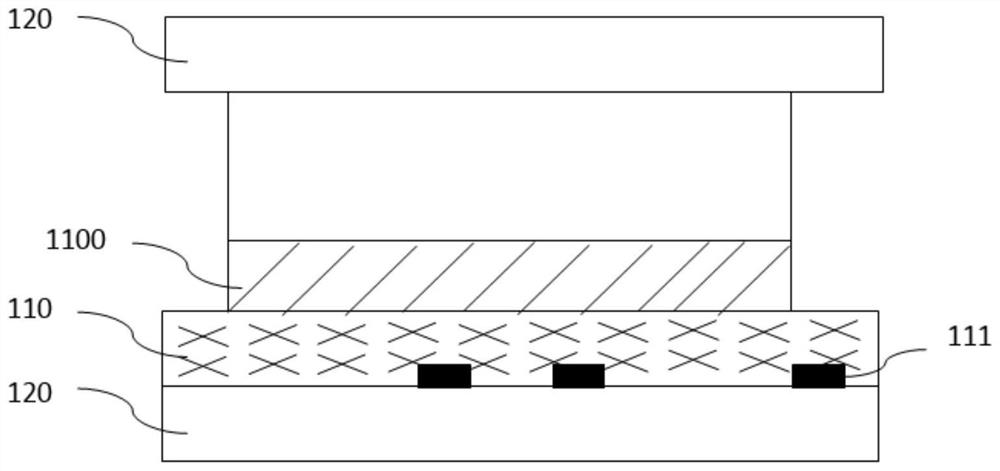

[0048] figure 1 A schematic structural view of the anti-counterfeiting film 100 provided by the embodiment of the present application is shown, figure 2 show figure 1 Sectional view along line AA, image 3 show figure 1 Sectional view along line BB; see Figure 1-Figure 3 , the present embodiment provides an anti-counterfeit film 100, the anti-counterfeit film 100 mainly includes a holographic information layer 001 and a base film 120; in the process of use, the adhesive layer 1100 of the anti-counterfeit film 100 is attached to objects such as cards; then the base film is separated 120. Leave the holographic information layer 001 on the surface of objects such as cards.

[0049] see figure 2 , the following is an example of the main structure of the holographic information layer 001.

[0050] The holographic information layer 001 mainly includes a base layer 150 , an imaging layer 170 , a coating layer 180 and an adhesive layer 1100 which are sequentially stacked. Th...

Embodiment 2

[0090] Figure 4 It shows a schematic cross-sectional view of the identification assembly 200 provided by the embodiment of the present application, please refer to figure 2 and Figure 4 Embodiment 2 provides an identification component 200. The identification component 200 includes a substrate 210 and a holographic information layer 001. For the specific structure of the holographic information layer 001, please refer to Embodiment 1, which will not be repeated in this embodiment.

[0091] The glue layer 1100 of the holographic information layer 001 is connected with the base body 210 .

[0092] It can be understood that the substrate 210 can be a card, a card, etc. The embodiment of the present application does not limit the material of the substrate 210, and the identification component 200 has all the advantages of the above-mentioned holographic information layer 001.

[0093] The adhesive layer 1100 has good adhesion to the substrate 210, and the inside of the hologr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com