Object thickness measuring method, device and system based on ultrasonic waves, equipment and medium

An ultrasonic and thickness measurement technology, which is applied in the field of ultrasonic-based object thickness measurement, can solve the problems of different degrees of measured objects, small test values, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

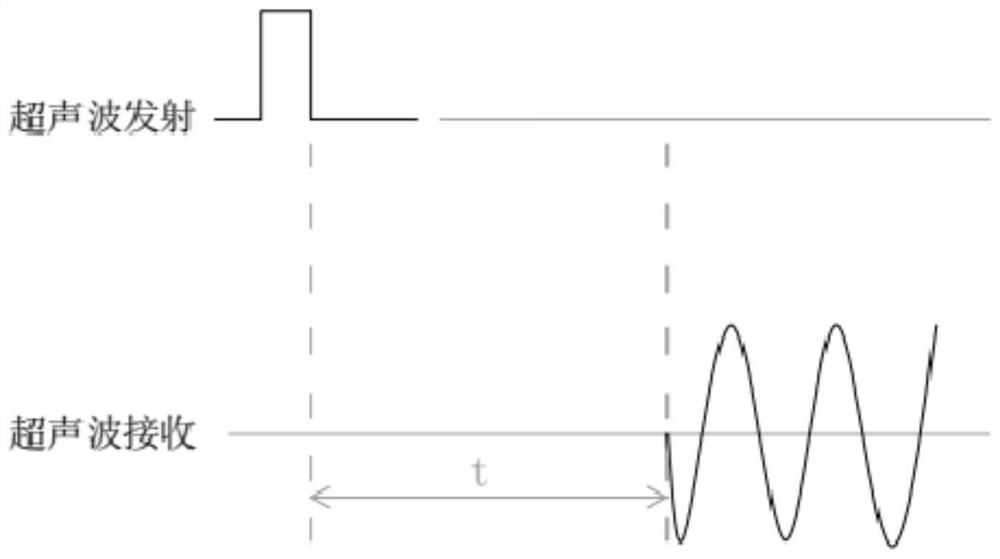

[0064] At present, most of the thickness measurement principles of ultrasonic thickness gauges on the market are to record the time from when the ultrasonic wave is emitted to when it is received, and then calculate the thickness according to the formula: , is the thickness of the material to be tested; is the propagation speed of ultrasonic waves in the tested material; is the propagation time of ultrasonic waves in the tested material.

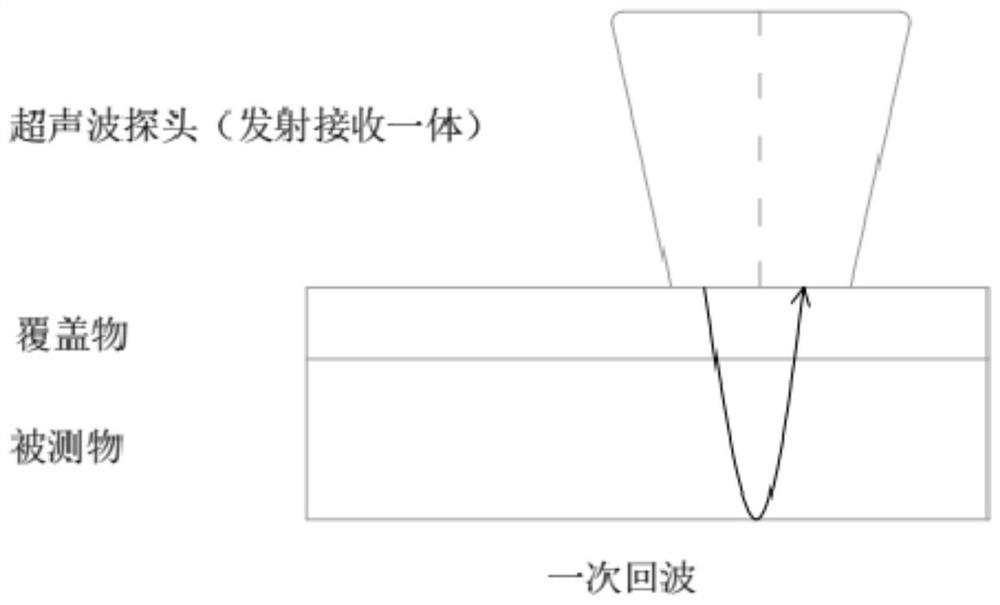

[0065] like figure 1 and figure 2 , according to the currently used test method, detect the moment when the waveform returns for the first time, record the measurement time, and then calculate the thickness of the measured object according to the thickness calculation formula. This method can measure the measured object without covering, but this The disadvantage of this method is that it cannot effectively remove the influence of the covering, and when the thickness of the covering cannot be ignored, the measurement result of the ...

Embodiment 3

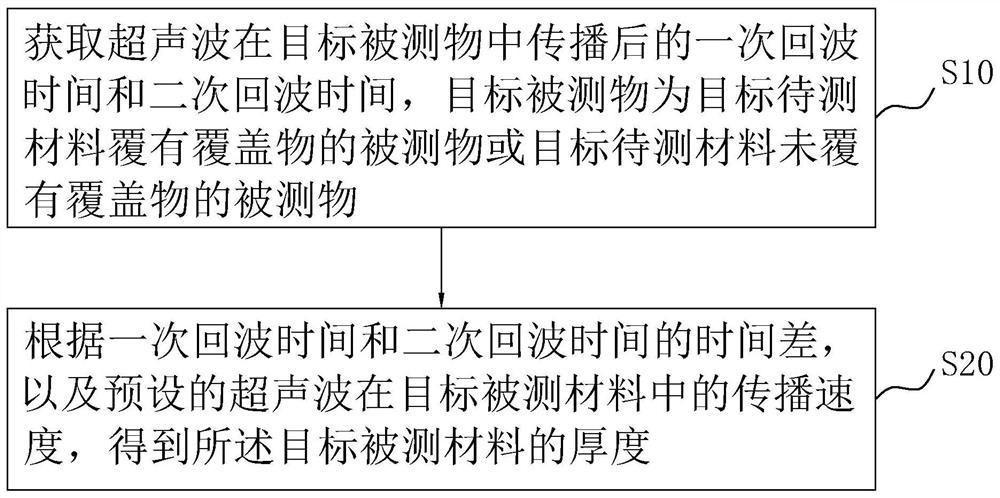

[0122] In one embodiment, an object thickness measurement device based on ultrasound is provided, and the object thickness measurement device based on ultrasound corresponds to the object thickness measurement method based on ultrasound in the above embodiments. like Figure 13 As shown, the ultrasonic-based object thickness measuring device includes an echo time acquisition module 10 and a thickness calculation module 20 . The detailed description of each functional module is as follows:

[0123] The echo time acquiring module 10 is used to acquire the primary echo time and the secondary echo time after the ultrasonic wave propagates in the target measured object, the target measured object is the measured object covered with the target measured material or the target measured object The test material is not covered with the test object;

[0124] The thickness calculation module 20 is configured to determine the thickness of the target material to be tested according to the...

Embodiment 4

[0145] In one embodiment, a computer device is provided, which is the computer device in the ultrasonic-based object thickness measurement system of this embodiment. When the computer program is executed by a processor, an ultrasonic-based object thickness measurement system is implemented. Thick method, the specific implementation steps are as follows:

[0146] S10: Obtain the primary echo time and secondary echo time after the ultrasonic wave propagates in the target object under test, the target object under test is the object under test covered with the target material under test or the target material under test is not covered with cover of the measured object.

[0147] S20: Determine the thickness of the target material to be tested according to the time difference between the primary echo time and the secondary echo time, and the preset ultrasonic propagation speed in the target material to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com