Method for improving recovery ratio of shale oil

A recovery rate and shale oil technology, applied in chemical instruments and methods, production fluids, earthwork drilling and production, etc., can solve problems such as limited wave-absorbing capacity of shale matrix, large consumption of water resources, poor stability, etc., and achieve Promoting the process of extraction and diffusion, reducing the resistance of solid-liquid diffusion, and the effect of clean and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

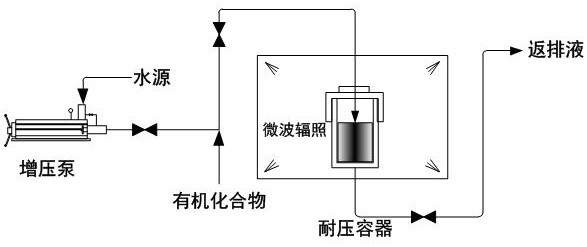

[0031] Embodiment 1: as figure 1 As shown, the method for enhancing shale oil recovery specifically includes the following steps:

[0032] (1) Take a columnar marine oil shale sample from the oil shale reservoir;

[0033] (2) Put the columnar shale sample into a pressure-resistant wave-transparent container;

[0034] (3) The columnar shale in the pressure-resistant wave-transparent container in step (2) is subjected to hydraulic fracturing with high-pressure water flow mixed with methanol, and the microwave irradiation device is turned on at the same time to carry out shale oil exploitation; methanol in the fracturing fluid The molar percentage is 10%, the hydraulic fracturing pressure is 20 MPa, and the flow rate is 0.1 m 3 / min, the microwave frequency is 2450 MHz, and the microwave irradiation power is 1000 W;

[0035] (4) Use liquid chromatography to determine the shale oil content in the fracturing recovery fluid, and then determine the recovery rate of shale oil;

...

Embodiment 2

[0040] Embodiment 2: as figure 1 As shown, the method for enhancing shale oil recovery specifically includes the following steps:

[0041] (1) Take a columnar marine oil shale sample from the oil shale reservoir;

[0042] (2) Put the columnar shale sample into a pressure-resistant wave-transparent container;

[0043] (3) The columnar shale in the pressure-resistant wave-transparent container in step (2) is subjected to hydraulic fracturing with high-pressure water flow mixed with methanol, and the microwave irradiation device is turned on at the same time to carry out shale oil exploitation; methanol in the fracturing fluid The molar percentage is 15%, the hydraulic fracturing pressure is 24 MPa, and the flow rate is 0.2 m 3 / min, the microwave frequency is 2450 MHz, and the microwave irradiation power is 1400 W;

[0044] (4) Use liquid chromatography to determine the shale oil content in the fracturing recovery fluid, and then determine the recovery rate of shale oil;

...

Embodiment 3

[0049] Embodiment 3: as figure 1 As shown, the method for enhancing shale oil recovery specifically includes the following steps:

[0050] (1) Take a columnar marine oil shale sample from the oil shale reservoir;

[0051] (2) Put the columnar shale sample into a pressure-resistant wave-transparent container;

[0052] (3) The columnar shale in the pressure-resistant wave-transparent container in step (2) is subjected to hydraulic fracturing with high-pressure water flow mixed with ethanol, and the microwave irradiation device is turned on at the same time to carry out shale oil exploitation; ethanol in the fracturing fluid The molar percentage is 20%, the hydraulic fracturing pressure is 28 MPa, and the flow rate is 0.3 m 3 / min, the microwave frequency is 2450 MHz, and the microwave irradiation power is 1800 W;

[0053] (4) Use liquid chromatography to determine the shale oil content in the fracturing recovery fluid, and then determine the recovery rate of shale oil;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com