Annealing process of 04Cr13Ni5Mo super martensitic stainless steel medium plate for water and electricity

A technology of martensitic stainless steel and annealing process, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of small number of furnaces, low production efficiency, and unstable performance, so as to improve the surface quality of products and increase production efficiency , the effect of uniform cooling environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

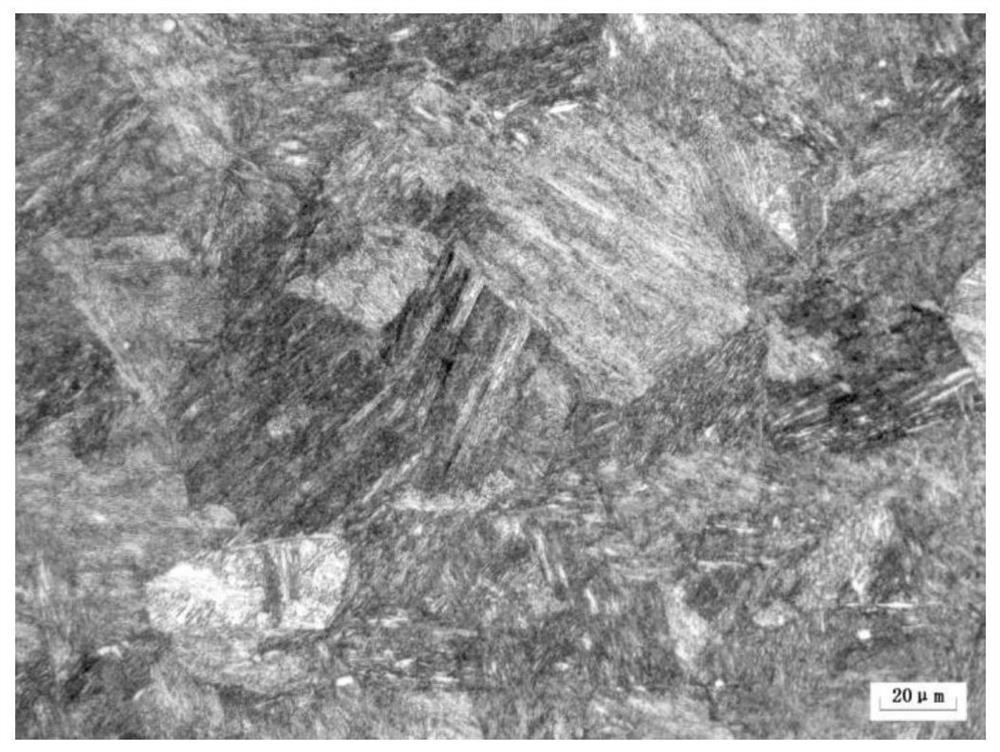

Image

Examples

Example Embodiment

[0020]Example 1

[0021]Step 1. Pickling: 10 pieces of 60mm thick 04Cr13Ni5Mo hot-rolled super martensitic stainless steel medium-thick plates are cut to length without annealing process, pickled directly in the continuous pickling line, and continuously enters the pickling line. Shot blasting current 65-75A, throwing speed 2000-2300r / min, using "mixed acid pickling" process, HF solution: 55-70g / L, HNO3Solution: 120-150g / L, temperature: 60-70℃, pickling speed 5-8m / min. The hot-rolled oxide scale is pickled and cleaned once.

[0022]Step 2. After pickling, 10 pieces of 04Cr13Ni5Mo steel plates are continuously loaded at the entrance of the continuous annealing furnace and normalized. The normalizing temperature is 1050-1100℃, the heating time is 60min, and the holding time: 120min. The steel plate is in the annealing furnace. As the roller table swings in the furnace, the normalized steel plate slowly exits the annealing furnace exit door along with the roller table, enters the quenching m...

Example Embodiment

[0025]Example 2

[0026]Step 1. Pickling: 10 pieces of 04Cr13Ni5Mo hot-rolled super martensitic stainless steel medium-thick plates with a thickness of 20mm are cut to length without annealing process, pickled directly in the continuous pickling line, and continuously enters the pickling line. Shot blasting current 65-75A, throwing speed 2000-2300r / min, using "mixed acid pickling" process, HF solution: 55-70g / L, HNO3Solution: 120-150g / L, temperature: 60-70℃, pickling speed 5-8m / min; pickling clean the hot-rolled oxide scale at one time.

[0027]Step 2. After pickling, 10 pieces of 04Cr13Ni5Mo steel plates are continuously loaded at the entrance of the continuous annealing furnace and normalized. The normalizing temperature is 1050-1100℃, the heating time is 20min, and the holding time: 40min. The steel plate is in the annealing furnace. As the roller table swings in the furnace, the normalized steel plate slowly exits the annealing furnace exit door along with the roller table, enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com