A kind of production technology of industrialized isopentenol

A technology of prenol and production process, applied in the field of industrialized prenol production process, can solve the problems of complex process and high production cost, and achieve the effects of high yield, high selectivity and optimized material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

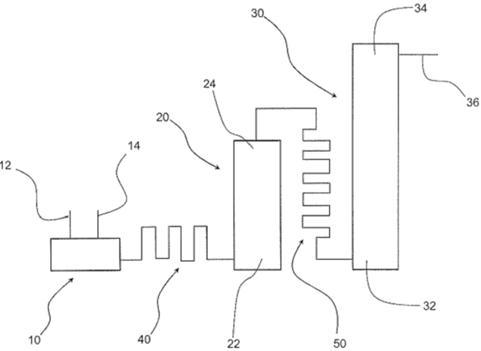

Image

Examples

Embodiment 1

[0066] The mixture of alkaline isobutylene and paraformaldehyde enters the storage tank, wherein the paraformaldehyde has a medium degree of polymerization of 30 and a particle size of 400-800 microns. The molar ratio of basic isobutylene to paraformaldehyde is 12:1.

[0067] The mixed suspension of alkaline isobutylene and paraformaldehyde is kept in a stirring state in the tank, and the mixture is sent to the heat exchanger through a pump to make the temperature of the mixture reach 190 ° C. The heated suspension is sent to a height of 5.5 meters and a diameter of 1.5 In the first plug flow reactor, paraformaldehyde is depolymerized in the first reactor, and the reaction condition is a pressure of 7 MPa for 50 minutes. The end point of the depolymerization reaction is to obtain a mixture of basic isobutylene, free formaldehyde and undepolymerized paraformaldehyde at the top of the reactor at a temperature of 170°C.

[0068] When the mixture enters the second heat exchanger ...

Embodiment 2~4

[0073] Prenol was prepared according to the method in Example 1, except that the temperature and pressure of depolymerization were carried out according to Table 1.

[0074] The temperature and pressure of depolymerization in table 1 embodiment 2~4

[0075]

[0076] It can be seen from Table 1 that during the depolymerization process of the suspension of paraformaldehyde and basic isobutylene at a temperature of 120-220 °C, there is a positive correlation between the reaction parameters temperature and pressure and the depolymerization rate of paraformaldehyde.

Embodiment 5~8

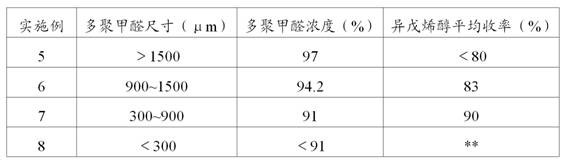

[0078] Prenol was prepared according to the method in Example 1, except that the particle size and concentration of paraformaldehyde in Examples 5-8 were carried out according to Table 2.

[0079] The size and concentration of paraformaldehyde in table 2 embodiment 5~8

[0080]

[0081] Note: "**" means that in Example 8, paraformaldehyde with a particle size of less than 300 μm is used, which is very easy to form large aggregates in the solution. Experiments have proved that isobutylene has no ability to diffuse such large aggregates to form the uniformity required for depolymerization. Mutually. Therefore, if the homogeneous phase required for depolymerization is satisfied, water must be injected, resulting in an increase in energy consumption ratio, which adversely affects the depolymerization process. In addition, due to the presence of moisture, it is difficult to ensure that the water content in the final product is less than 0.1%.

[0082] Concentrations of parafor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com