Green preparation method and application of offshore polluted sediment remediation material

A technology for remediating materials and sediments, which is applied in the field of green preparation of remediation materials for offshore polluted sediments, and can solve the problem that the remediation materials are difficult to apply to in-situ remediation of marine sediments, limit the large-scale application of bio-enhancement technologies, and improve the biological effectiveness of heavy metals, etc. problem, to achieve the effect of improving bioremediation efficiency, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

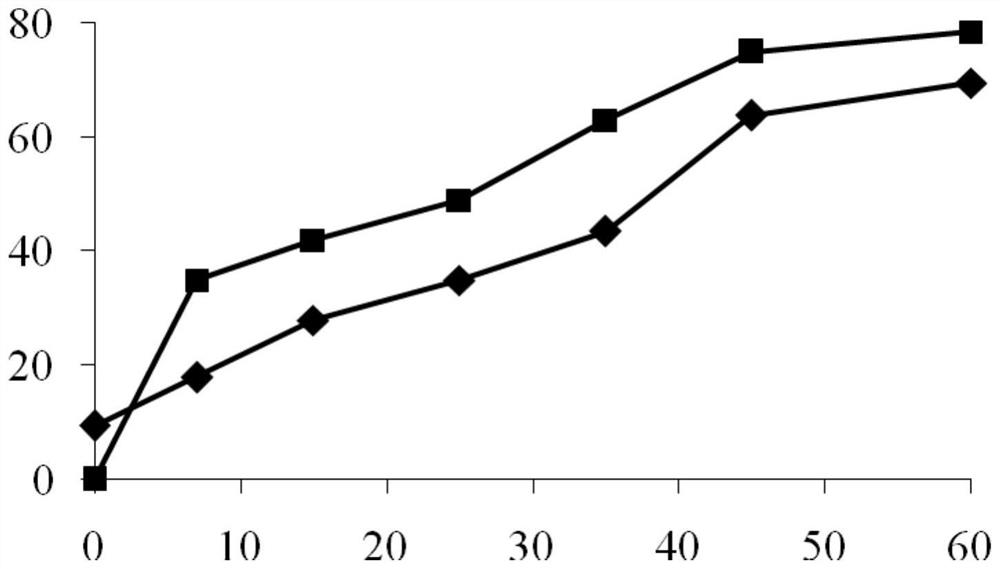

Image

Examples

Embodiment 1

[0024] (1) Preparation of seaweed extract

[0025] Collect offshore kelp, remove surface sediment, chop it and mix it with water at a mass ratio of 1:40, place it in a reactor, control the temperature at 120°C, and react for 150 minutes. After the liquid is separated, the precipitate is recovered, and the liquid phase is diluted 5 times with water, which is the seaweed extract;

[0026] (2) Green preparation of magnetic composite materials

[0027] Add the above-mentioned seaweed extract into the reactor, control its volume to be half of the reactor, add FeSO 4 ·7H 2 O, controls Fe 2+ The concentration is 0.05mol / L, and the reactor is sealed; then stirred at 800r / min for 20min, and the pH is controlled to be 10 during the stirring process; after the solid-liquid separation of the obtained suspension, the precipitate is washed twice with water and dried in vacuum to obtain a magnetic composite material ;

[0028] (3) Remediation of polluted sediments

[0029] Total petrol...

Embodiment 2

[0031] (1) Preparation of seaweed extract

[0032] Collect offshore kelp, remove surface sediment, chop it and mix it with water at a mass ratio of 1:50, place it in a reactor, control the temperature at 130°C, and react for 120 minutes. Cool to room temperature, and the mixed solution in the reactor is solidified After the liquid is separated, the precipitate is recovered, and the liquid phase is diluted 5 times with water, which is the seaweed extract;

[0033] (2) Green preparation of magnetic composite materials

[0034] Add the above-mentioned seaweed extract into the reactor, control its volume to be half of the reactor, add FeSO 4 ·7H 2 O, controls Fe 2+ The concentration is 0.06mol / L, and the reactor is closed; then stirred at 1000r / min for 15 minutes, and the pH is controlled to be 10 during the stirring process; after the solid-liquid separation of the obtained suspension, the precipitate is washed twice with water and dried in vacuum to obtain a magnetic composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com