Cutting device for plastic film processing

A technology of plastic film and cutting device, which is applied in the direction of thin material processing, transportation and packaging, and winding strips. Tension force, utilization efficiency improvement, frictional force improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

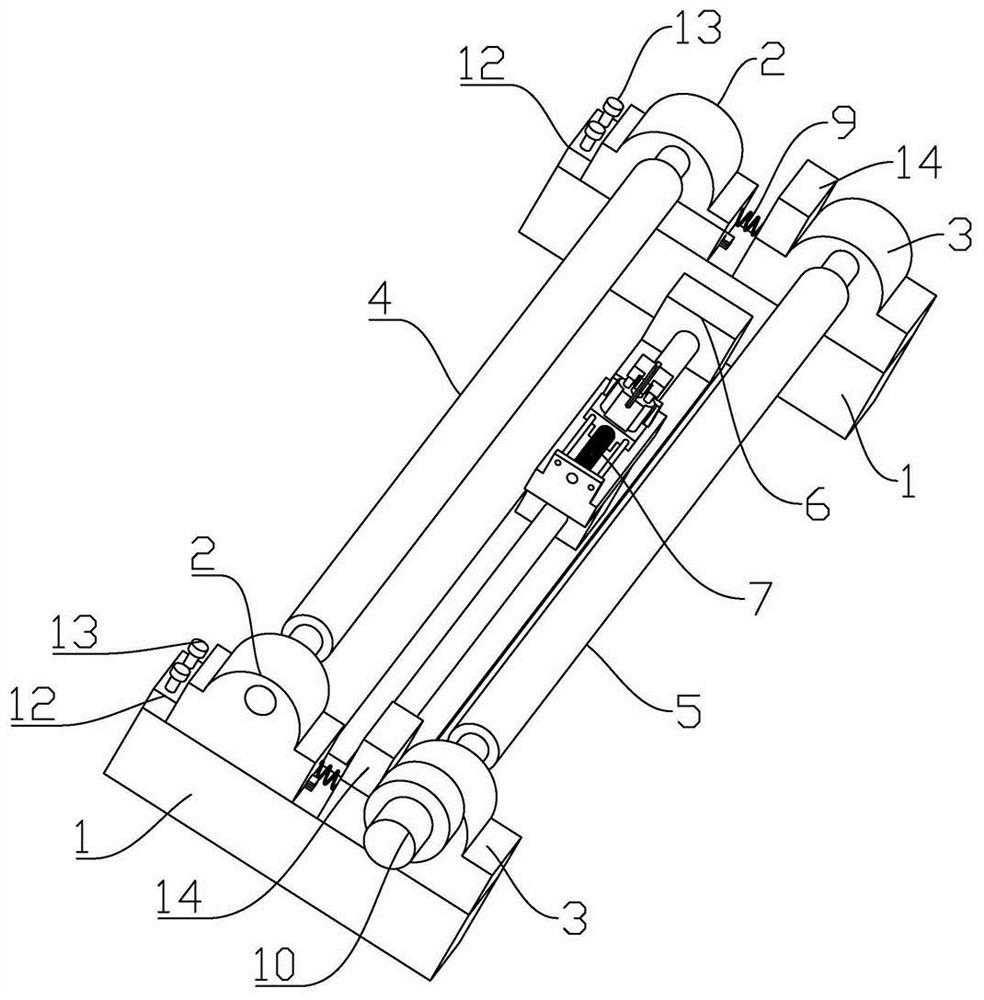

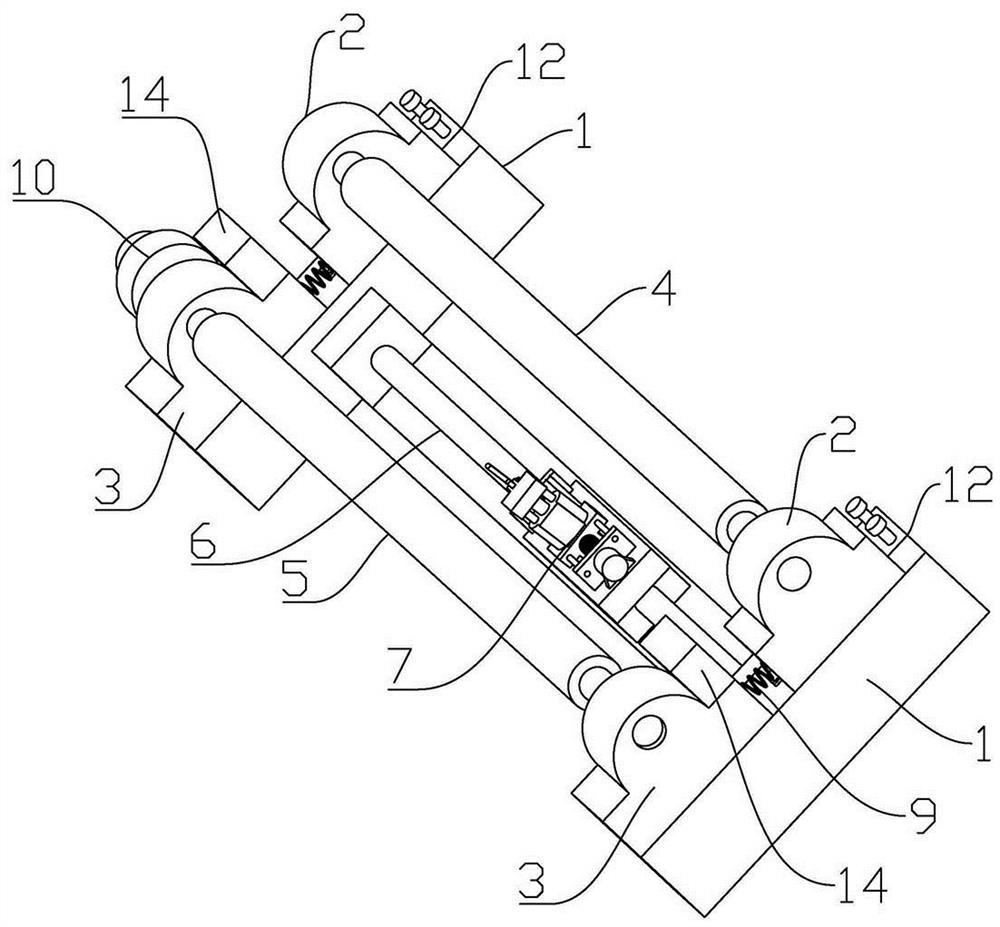

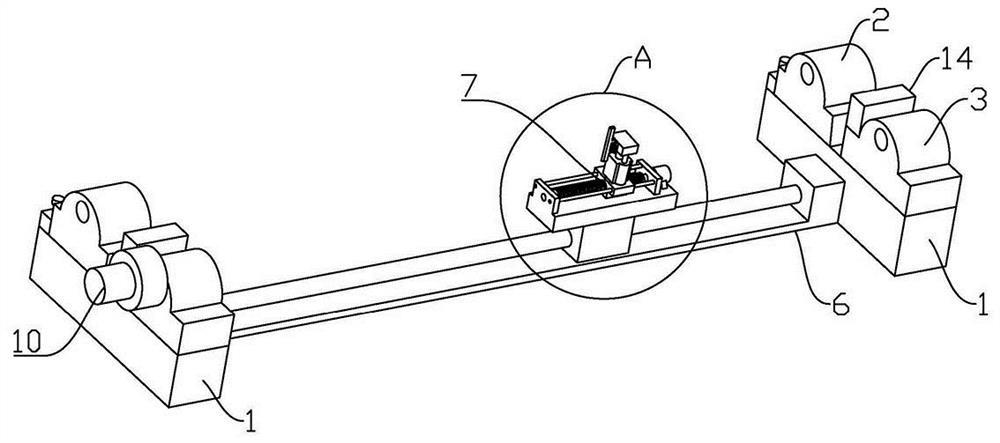

[0030] like Figure 1-7As shown, a cutting device for plastic film processing includes two reversing frames 1 arranged parallel to each other on the same plane, a first bearing seat 2 and a second bearing seat 3 respectively fixed on the upper end surface of each reversing frame 1, two The flattening roller 4 whose two ends are respectively connected in the first bearing seat 2, the transition roller 5 whose two ends are respectively connected in the second bearing seat 3, the rodless cylinder assembly 6 whose two ends are respectively fixed on the inner sides of the two turning frames 1, A cutting assembly 7 and a cutting control system fixed on the rodless cylinder assembly 6 . The overturning frame 1 is installed on both sides of the winding equipment. The overturning frame stays at the bottom of the winding equipment during daily work. During the cutting operation, the turning machine of the overturning frame is reset by a hydraulic cylinder or an air cylinder. Set on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com