Laminated latex silk quilt and preparation method thereof

A silk quilt, layered technology, applied in the field of silk quilts, can solve the problems such as the cleaning problem of latex silk quilts that have not been considered, and achieve the effects of improving economic value and use value, avoiding material accumulation, and improving sleep quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

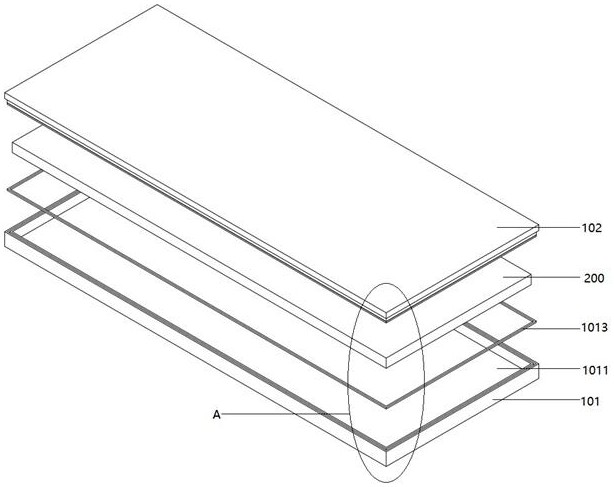

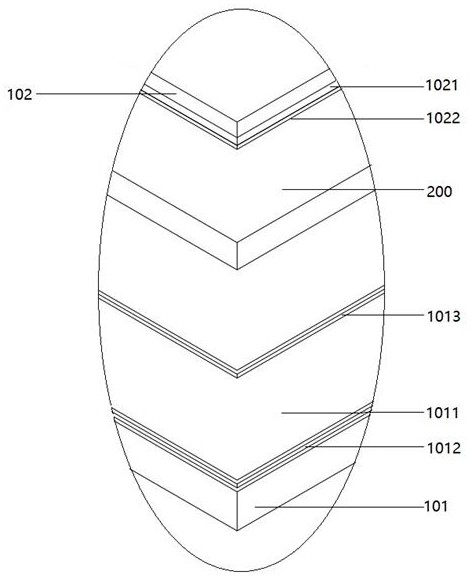

[0047] See attached Figure 1-3 , a laminated latex silk quilt, comprising:

[0048] The latex layer 100, the latex layer 100 comprises a lower quilt 101 and an upper quilt 102, wherein the upper surface of the lower quilt 101 is concavely provided with a first accommodating groove 1011 and a second accommodating groove 1012, and the first accommodating groove 1011 is located at the bottom The middle position of the quilt body 101; the second accommodating groove 1012 is located at the outer periphery of the first accommodating groove 1011; the first magnetic part 1013 is fixed in the second accommodating groove 1012; the lower surface of the upper quilt body 102 is integrally formed with the second The connecting bar 1021 corresponding to the position of the accommodating groove 1012, the connecting bar 1021 is accommodated in the second accommodating groove 1012, and the lower end of the connecting bar 1021 is fixed with a second magnetic part 1022 which is attracted to the fi...

Embodiment 2

[0051] A preparation method for laminated latex silk quilt, comprising the following steps:

[0052] (1) Weigh by weight: 140kg of natural latex, 25kg of foaming agent, 8kg of graphene, 12kg of Huoxiang, 7kg of cicada slough, 10kg of Vitex, 16kg of bean root, 12kg of Prunella vulgaris, 10kg of Albizia juniper and 9kg of Morus alba ;

[0053] (2) Grind Huoxiang, Cicada, Vitex, Bean Root, Prunella vulgaris, Albizia Julibrissin and Morus alba, respectively, pass through a 80-mesh sieve, mix, add 15 times the quality of water and decoct 3 times, the first time 2.5h, for the second time and 2h for the second time, filter and combine the filtrates;

[0054] (3) Grinding the graphene through a 120-mesh sieve;

[0055] (4) Deamination the natural latex, import it into the stirring container, then add the foaming agent, the filtrate of step (2) and the graphene powder of step (3), heat and maintain it at 30°C, at a speed of 500r / min , stirring and foaming for 40-60min to obtain foam...

Embodiment 3

[0060] A preparation method for laminated latex silk quilt, comprising the following steps:

[0061] (1) Weigh by weight: 130kg of natural latex, 20kg of foaming agent, 10kg of graphene, 10kg of Huoxiang, 6kg of cicada slough, 8kg of Vitex, 13kg of bean root, 9kg of Prunella vulgaris, 8kg of Albizia juniper and 6kg of Morus alba ;

[0062] (2) Grind Huoxiang, Cicada, Vitex, Bean Root, Prunella vulgaris, Albizia Julibrissin and Morus alba, respectively, pass through a 70-mesh sieve, mix, add 13 times the quality of water and decoct 3 times, the first time 2.5h, for the second time and 2h for the second time, filter and combine the filtrates;

[0063] (3) Grinding the graphene through a 130-mesh sieve;

[0064] (4) Deamination the natural latex, import it into the stirring container, then add the foaming agent, the filtrate of step (2) and the graphene powder of step (3), heat and maintain it at 27°C, at a speed of 500r / min , stirring and foaming for 50min to obtain foamed la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com