Bulletproof helmet body and preparation method thereof

A bulletproof helmet and helmet body technology, which is applied in the direction of protective equipment, protective equipment, chemical instruments and methods, etc., can solve the problem of the number of layers and uniform thickness of difficult-to-lap joints, unstable bulletproof performance of the helmet, and uneven surface density of the helmet body and other problems, to avoid tensile fracture damage, ensure bulletproof performance, and maintain the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

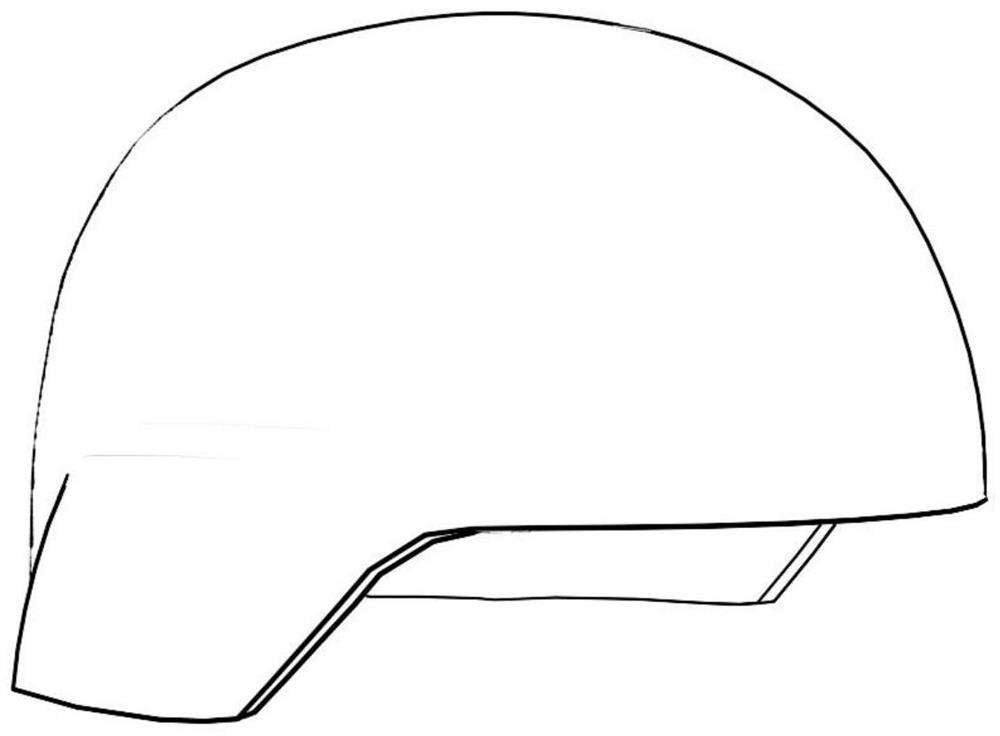

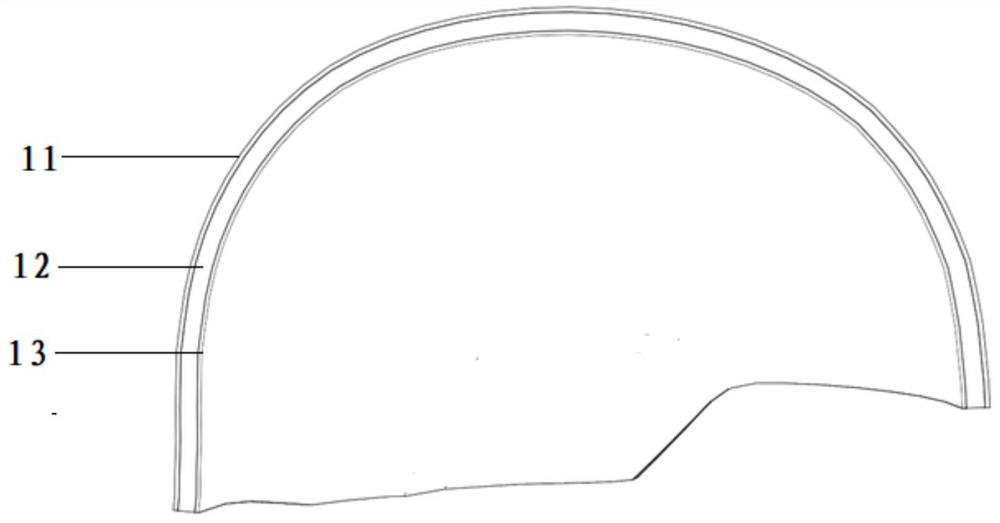

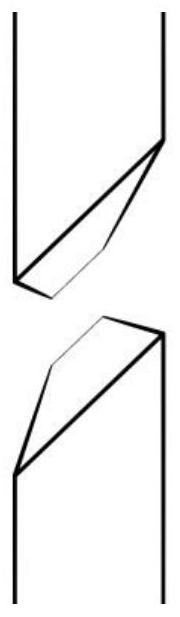

[0038] Such as Figure 1-2 Shown is a schematic structural view of the body of the bulletproof helmet provided by the present invention, including an outer layer 11 , a middle layer 12 and an inner layer 13 . Wherein, the outer layer 11 and the inner layer 13 are respectively composed of two layers of carbon fiber plain weave fabric prepregs covered with phenolic resin film; Figure 5 As shown, the middle layer 12 is formed by bonding and splicing three split bodies (the upper split body 31, the left split body 32, and the right split body 33). image 3 As shown, the overlapping width of each split beveled surface 34 is 7 mm; the angle of the beveled face 34 is 30°, and each split is composed of 48 layers of ultra-high molecular weight polyethylene non-weft prepreg impregnated with polyurethane; the outer layer 11 1. The single-layer density of the fabric prepreg used in the inner layer 13 is 150g / m 2 , the film content is 15wt% of the surface density of the single-layer fab...

Embodiment 2

[0046] The body of the bulletproof helmet in this embodiment comprises an outer layer 11, a middle layer 12 and an inner layer 13. Among them, the outer layer 11 and the inner layer 13 are respectively composed of two layers of carbon fiber plain fabric prepreg coated with epoxy resin film, and the middle layer 12 is composed of four splits (front split 41, rear split 42, left split Split body 43, right split body 44) are bonded and assembled, such as Figure 4 As shown, the junction of each split body is a step-type overlapping surface 45, and the overlapping width of each split-type step-type overlapping surface 45 is 4mm; each split body is composed of 48 layers of impregnated styrene-isoprene-styrene block Copolymer ultra-high molecular weight polyethylene non-weft prepreg composite composition; the fabric prepreg used in the outer layer 11 and inner layer 13 has a single layer density of 150g / m 2 , the film content is 15wt% of the surface density of the single-layer fabri...

Embodiment 3

[0054] The body of the bulletproof helmet in this embodiment comprises an outer layer 11, a middle layer 12 and an inner layer 13. Wherein, the outer layer 11 and the inner layer 13 are respectively composed of two layers of glass fiber plain weave fabric prepregs coated with epoxy resin film; Rear split body 53, left split body 54, right split body 55) are bonded and assembled, as Figure 7 As shown, the joints of each split body are overlapping oblique cut surfaces 56, and the overlapping width of each split oblique cut surface 56 is 7mm; Aramid plain weave fabric prepreg composite composition; the fabric prepreg used in the outer layer 11 and the inner layer 13 has a single layer density of 200g / m 2 , the adhesive film content is 15wt% of the surface density of the single-layer fabric prepreg; the single-layer density of the fabric prepreg used in the middle layer is 380g / m 2 , the content of the phenolic resin film is 13wt% of the areal density of the single-layer fabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com