Bowl bottom polishing device for porcelain processing

A bowl bottom and porcelain technology, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of laborious operation and low work efficiency, and achieve the effects of improving work efficiency, facilitating collection, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

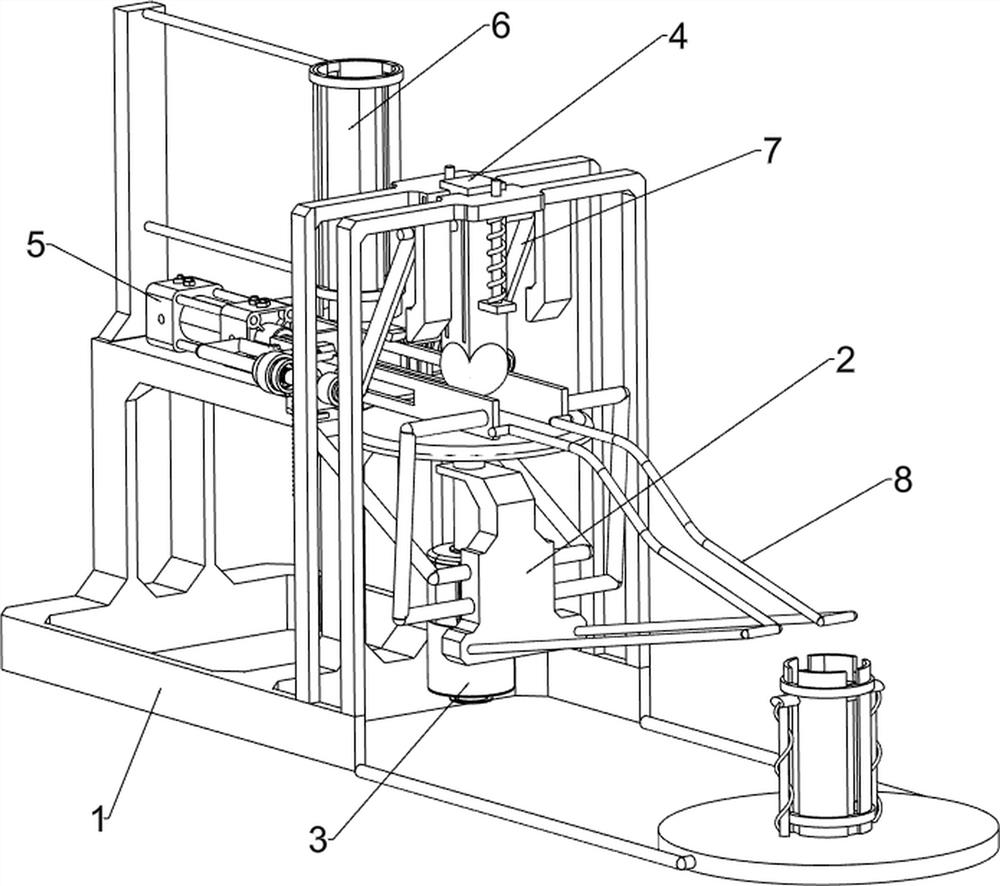

[0056] A bowl bottom grinding device for porcelain processing, such as figure 1 As shown, it includes a frame 1, a support table 2, a grinding mechanism 3 and a primary pressing mechanism 4. The right side of the frame 1 is connected with a support table 2, the support table 2 is connected with a grinding mechanism 3, and the middle part of the frame 1 is connected with a primary Press mechanism 4.

[0057] When people want to polish the bottom of the bowl, they first place the bowl on the grinding mechanism 3, and finally start the grinding mechanism 3, press the primary pressing mechanism 4 downward, so that the bowl is fixed, and the grinding mechanism 3 grinds the bottom of the bowl at the same time. Close the grinding mechanism 3 after completion, unclamp the primary pressing mechanism 4, and take out the bowl.

Embodiment 2

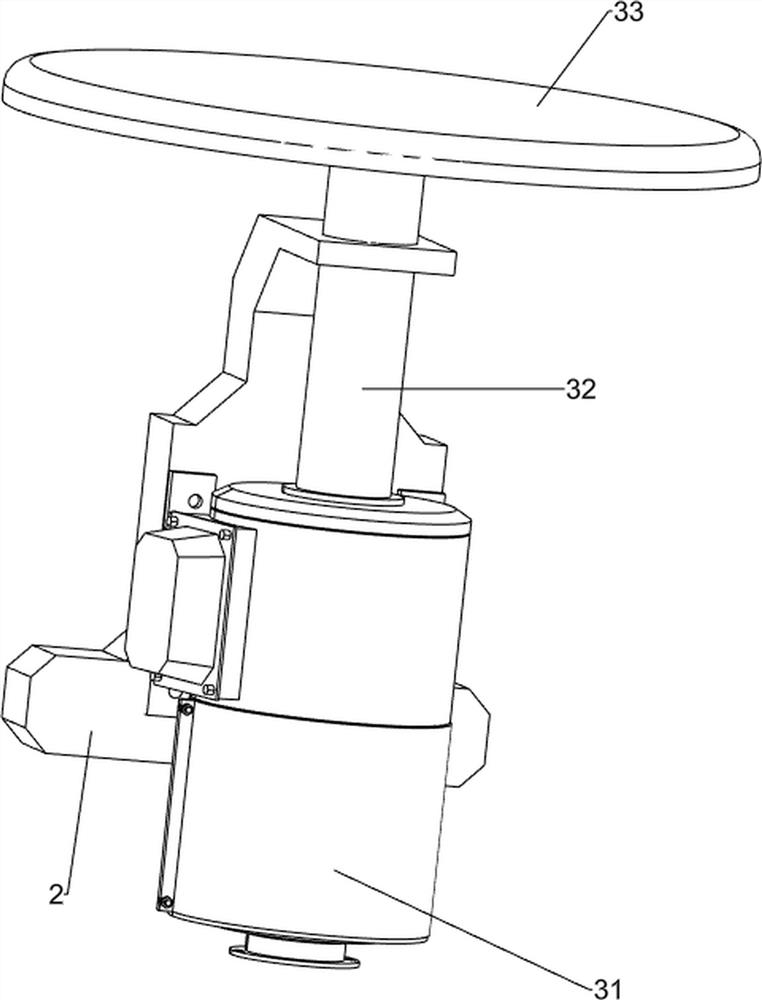

[0059] On the basis of Example 1, such as Figure 2-3 As shown, the grinding mechanism 3 includes a motor 31, a first transmission shaft 32 and a sand disc 33, the support table 2 is connected with a motor 31, the output shaft of the motor 31 is connected with a first transmission shaft 32, and the top of the first transmission shaft 32 is connected with a Sand tray 33.

[0060] When people want to polish the bottom of the bowl, the bowl is first placed on the sand tray 33, the motor 31 is started, and the output shaft of the motor 31 rotates to drive the first transmission shaft 32 and the sand tray 33 to rotate. Under the action of the primary pressing mechanism 4, The bottom of the bowl is polished, and after completion, the motor 31 is turned off and the bowl is taken out.

[0061] The primary pressing mechanism 4 includes a lower pressing block 41, a handle 42, a return spring 43 and an extension rod 44. The lower pressing block 41 is slidably connected to the middle upp...

Embodiment 3

[0064] On the basis of Example 2, such as Figure 4-9 As shown, a pusher mechanism 5 is also included. The pusher mechanism 5 includes a cylinder 51, a material retaining frame 52 and a forward block 53. The left side of the form frame 1 is connected with a cylinder 51, and the front and rear sides of the support table 2 are connected with a retainer. Frame 52, the material blocking frame 52 is located above the sand tray 33, and the forward block 53 is slidably connected between the material blocking frames 52, and the left side of the advancing block 53 is connected with the cylinder 51.

[0065] When people need to feed materials, first place the bowl on the left side of the frame 1, then start the cylinder 51, the cylinder 51 drives the forward block 53 to move to the right, push the bowl to the right onto the sand tray 33, and then close the cylinder 51. Drive advancing block 53 and move left and reset.

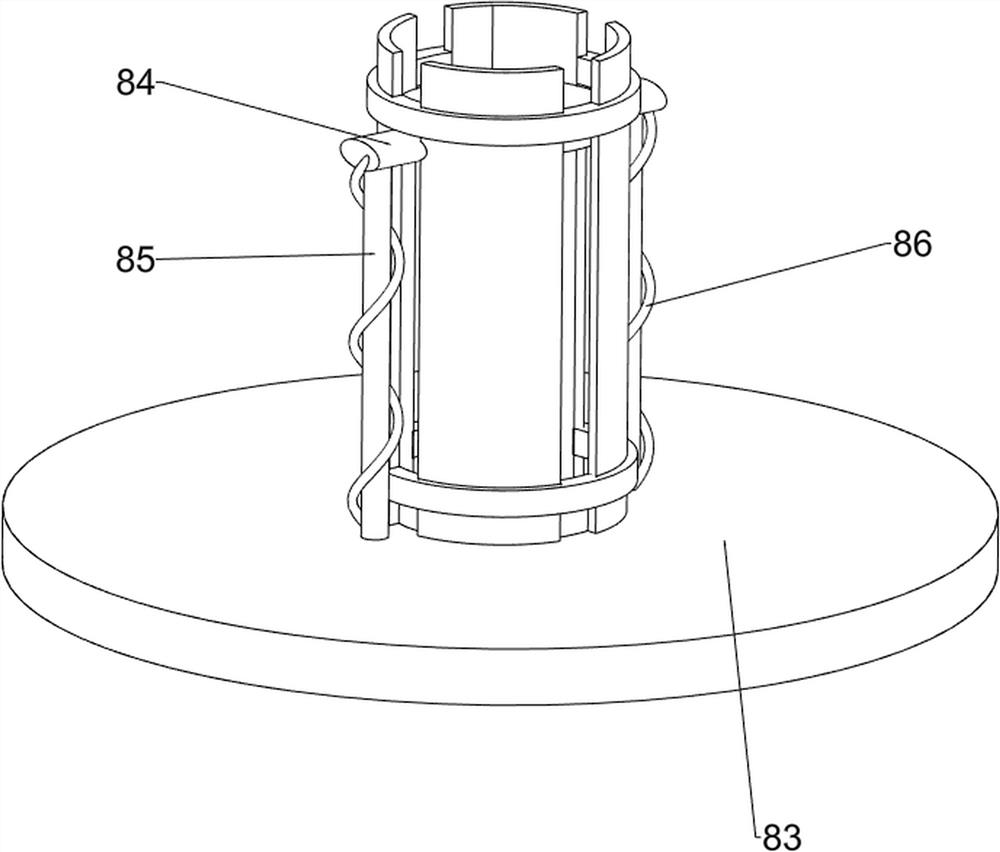

[0066] Also includes a discharge mechanism 6, the discharge mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com