Display screen assembling, locking and carrying device and method

A technology of handling device and display screen, applied in the field of display screen, can solve the problems of wear of screw bit rod, cumbersome disassembly steps, unfavorable protection of display screen end cover, etc., to achieve the effect of improving replacement efficiency and increasing covering area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

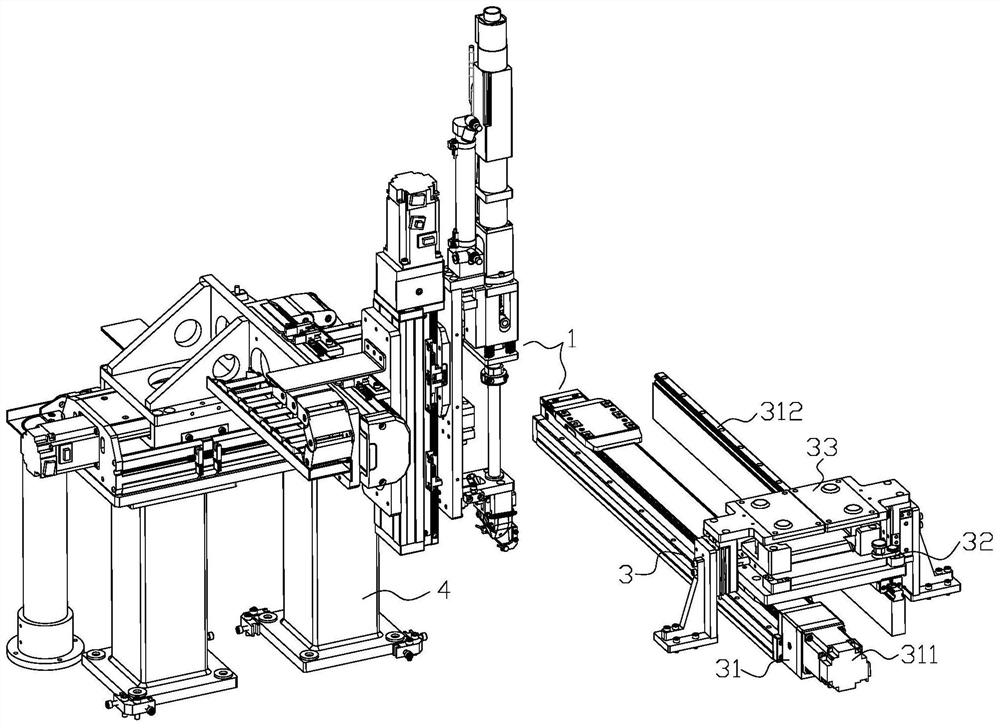

[0027] Such as figure 1 The shown locking transport device 1 includes a jig transport mechanism 3 and a locking mechanism 4; both the jig transport mechanism 3 and the locking mechanism 4 are fixed on the workbench; the input end and the output end of the jig transport mechanism 3 They are respectively connected with the feed port of the end cover of the display screen and the input end of the moving detection device, and the input end of the fixture handling mechanism 3 is matched with the end cover of the display screen; the output ends of multiple locking mechanisms 4 are respectively connected with the screw holes of the end cover of the display screen The fixture transport mechanism 3 is used to position and transport the end cover of the display screen; the locking mechanism 4 is used to lock a plurality of screws respectively on the screw holes of the end cover of the display screen.

[0028] The product flow direction of the end cover of the display screen is: the jig ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com