Machining lathe

A lathe and processing cavity technology, applied in the field of lathes, can solve problems such as splashing, affecting processing quality, surrounding safety, and surrounding hazards, and achieve the effects of protecting self-safety, avoiding self-triggering, and facilitating cleaning and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

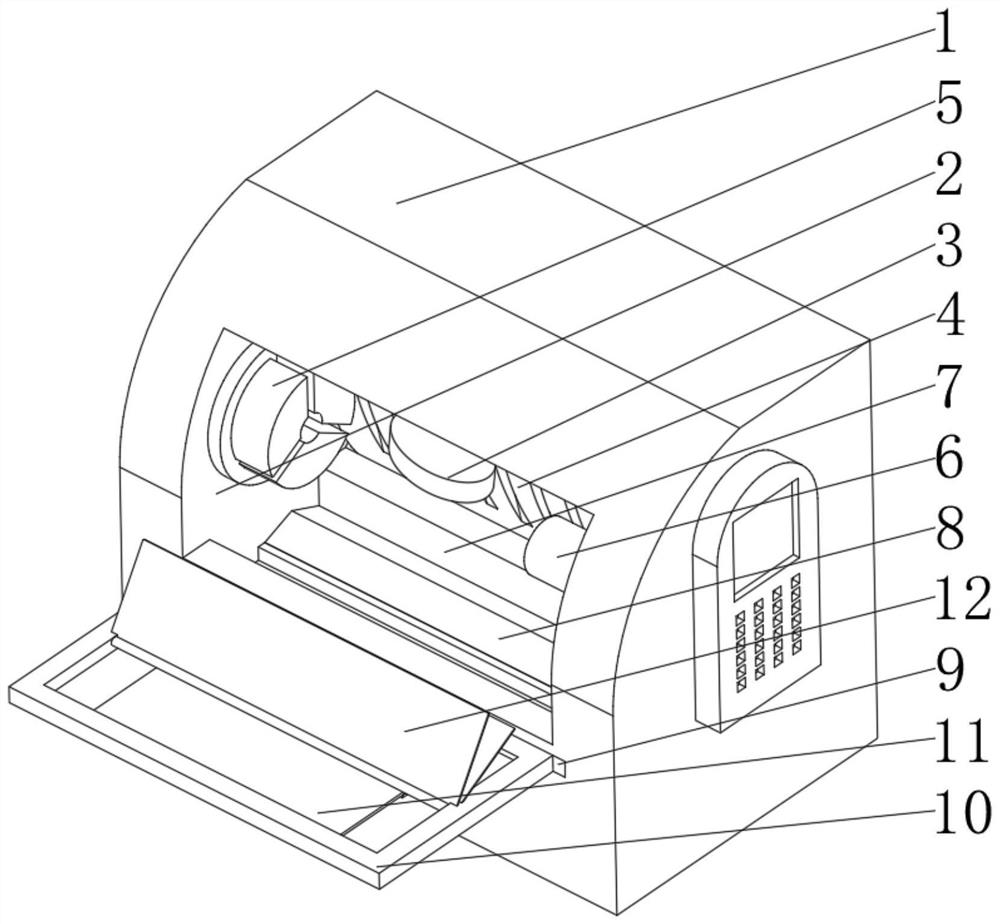

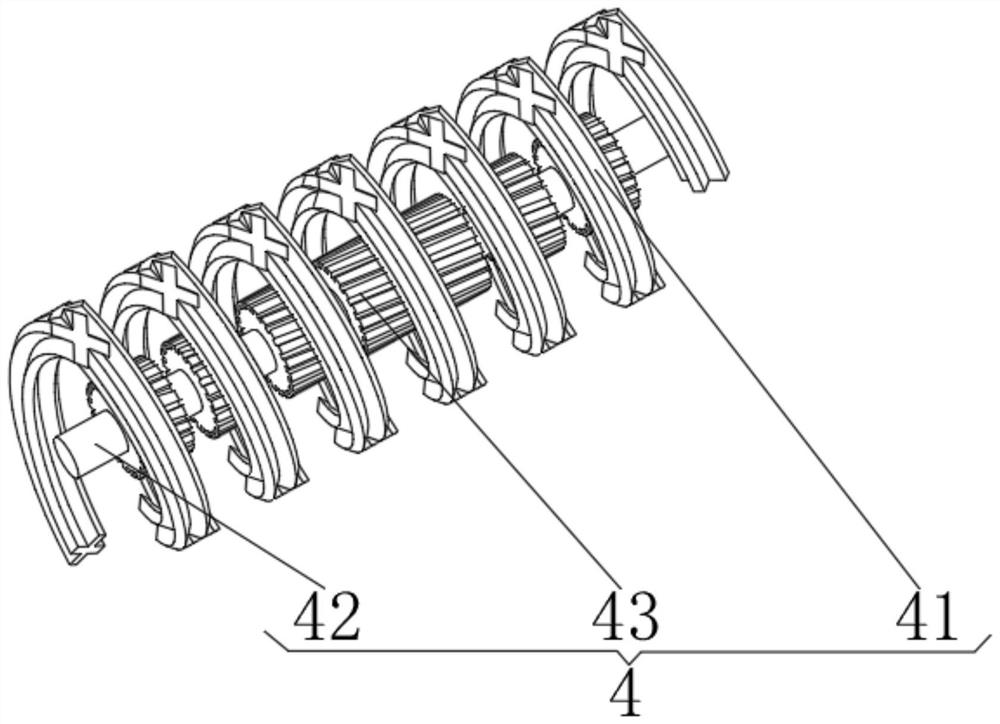

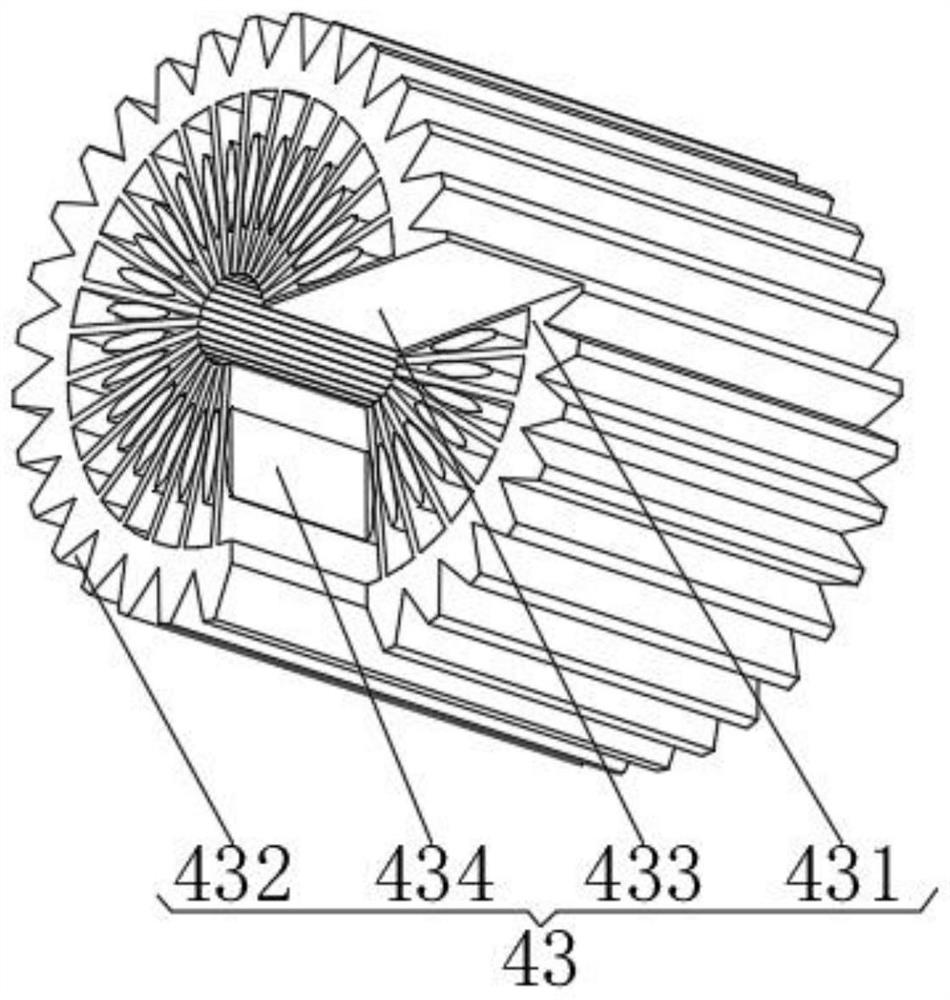

[0039] Such as Figure 1-6 As shown, a processing lathe proposed by the present invention includes a lathe body 1, a processing chamber 2 is provided in the middle of the front of the lathe body 1, a processing tool 3 is fixedly connected to the middle of the top of the processing chamber 2, and the back of the processing chamber 2 is A diversion mechanism 4 is fixedly connected, a three-jaw chuck 5 is provided in the middle of the left inner wall of the processing chamber 2, and an auxiliary fixing mechanism 6 is movably connected to the middle of the inner wall of the right inner wall of the processing chamber 2, and the middle of the bottom of the processing chamber 2 is The position is provided with a bottom groove 7, and the bottom of the inner cavity of the bottom groove 7 is fixedly connected with an electromagnet 8, and the front of the inner cavity of the bottom groove 7 is located above the electromagnet 8 and is provided with a cleaning groove 9, and the inner surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com