Self-anchored suspension bridge main cable tightening cable pretensioning device and method

A self-anchored suspension bridge and main cable technology, which is applied in the field of suspension bridge cable tightening, can solve the problems of affecting construction progress, scattered, low efficiency, etc., and achieve the effect of preventing scattered distribution and improving binding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

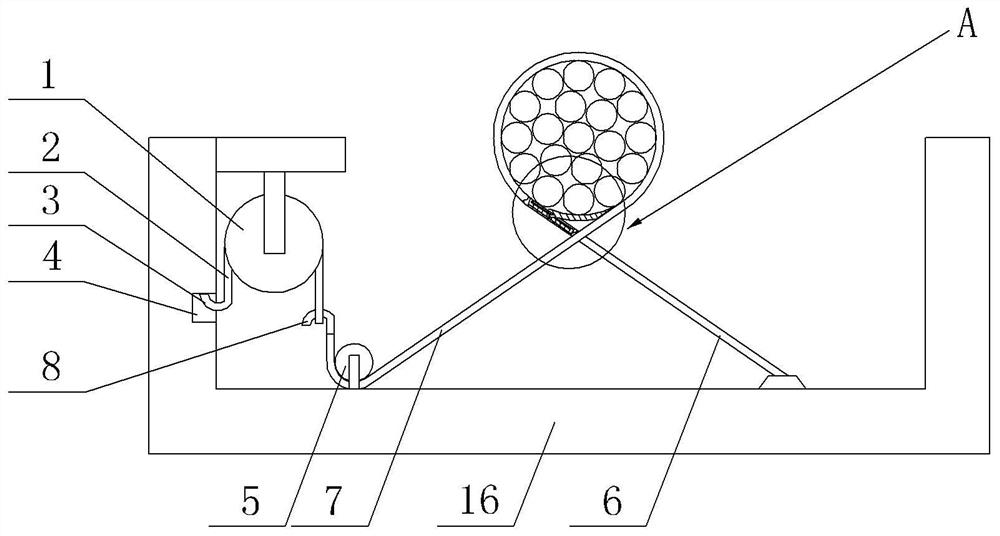

[0029] Embodiment one is basically as attached figure 1 , 2 Shown: as figure 1 The shown self-anchored suspension bridge main cable tensioning cable pretensioning device includes several pretensioning mechanisms and chain hoists 1 . Chain block 1 can choose Hsz type. Chain block 1 includes chain 2 and two hooks 3. The hooks 3 are welded to both ends of the chain 2. There is a gap 4 on the catwalk 16. The hook 3 on the left can Clamped in the gap 4, the catwalk 16 is also rotatably equipped with a pulley 5.

[0030] Each pretensioning mechanism all comprises the first pretensioning rope 6 and the second pretensioning rope 7, the right end of the first pretensioning rope 6 is welded with catwalk 16, the left end of the second pretensioning rope 7 is welded with hook 8, the second After the left end of the pre-tightening rope 7 walks around the pulley 5, the hook 8 is detachably connected with the suspension hook 3 .

[0031] Such as figure 2 As shown, the left end of the f...

Embodiment 2

[0038] Such as figure 2 As shown, the arc-shaped plate 11 is Y-shaped, and the right end of the arc-shaped plate 11 fits the middle part of the second pretensioning rope 7, and the left end of the arc-shaped plate 11 includes a first branch 14 and a second branch 15, and the first branch 14 is rotationally connected with the first pretensioning rope 6 at the slot 10 through a pin shaft, and the second branch 15 can be offset against the first pretensioning rope 6 . In addition if figure 1 The side wall of the pulley 5 shown has a groove, and the second pretensioning rope 7 is located in the groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com