Use method of conveyor with tension adjusting function

A technology of tension adjustment and conveyor, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of aluminum ingot material damage, slippage, and lower production efficiency, so as to achieve the goals of reducing load capacity, uniform efficiency, and improving feeding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

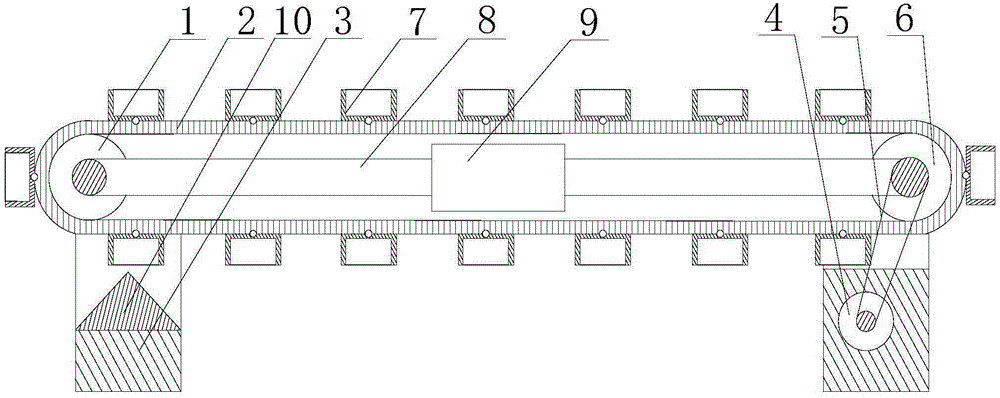

[0024] like figure 1 As shown, this embodiment includes the following steps:

[0025] A put the produced aluminum ingot semi-finished product into the hopper;

[0026] B Start the motor to drive the main roller to run, and the slave roller and the main roller are used together;

[0027] C The conveyor chain plate moves continuously from the roller to the direction of the main roller, and the hopper corresponds to the aluminum ingot one by one. When the hopper moves to the part of the conveyor chain plate facing the roller, the hopper turns over, and then the aluminum ingot is realized. transmission feed;

[0028] D After the hopper is overturned, the two interconnected inclined surfaces on the collecting block can receive the spilled debris and slide down to the bottom of the support seat along the inclined surface to facilitate the recycling of debris;

[0029] E When the transmission efficiency of the transmission chain plate is reduced or its tension is reduced, by turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com