Ultrasonic amplitude-change pole with frequency modulation sucker

A horn and ultrasonic technology, applied in the direction of magnetic attraction or thrust holding device, fluid using vibration, electrical components, etc., can solve problems such as difficult to achieve stable frequency modulation, achieve ingenious design, solve stable frequency modulation, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

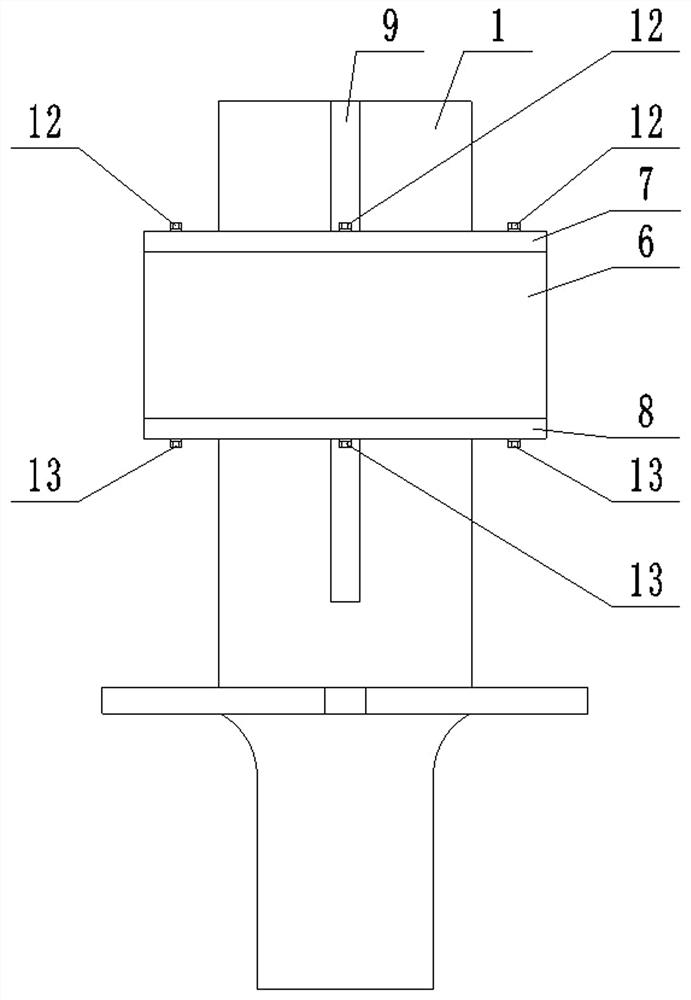

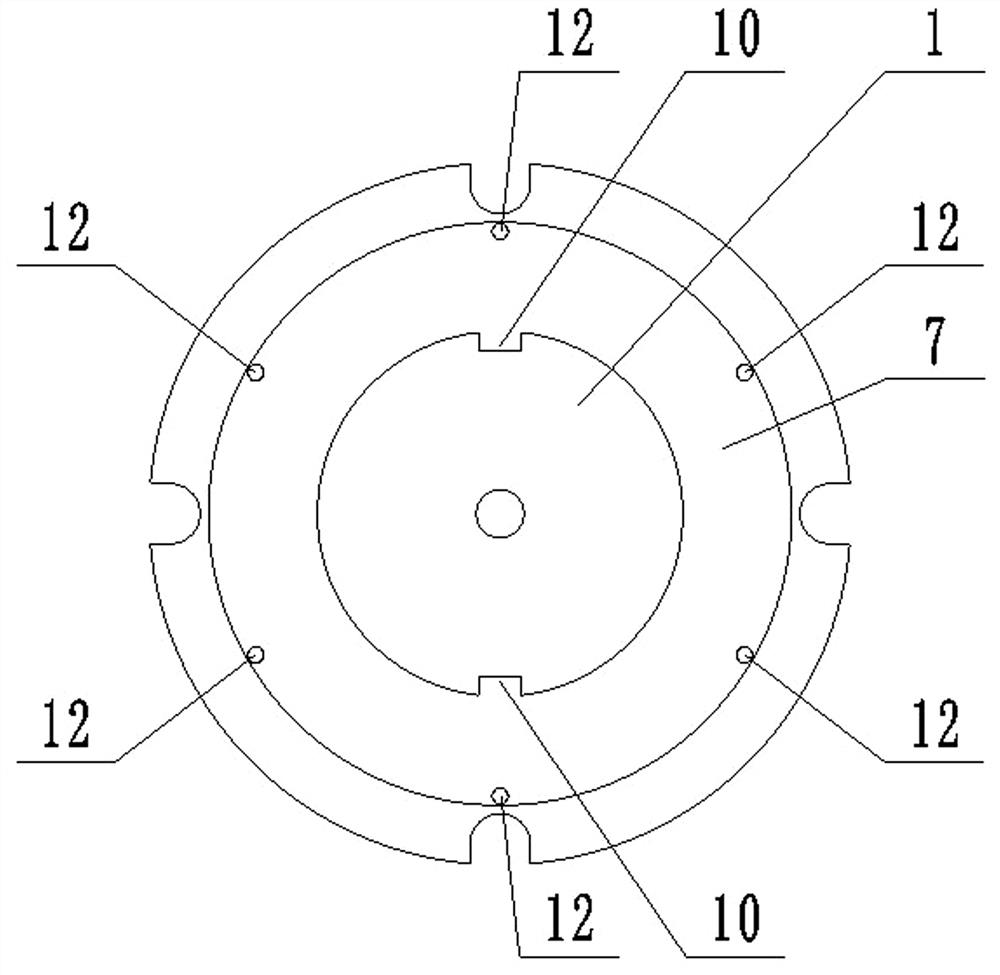

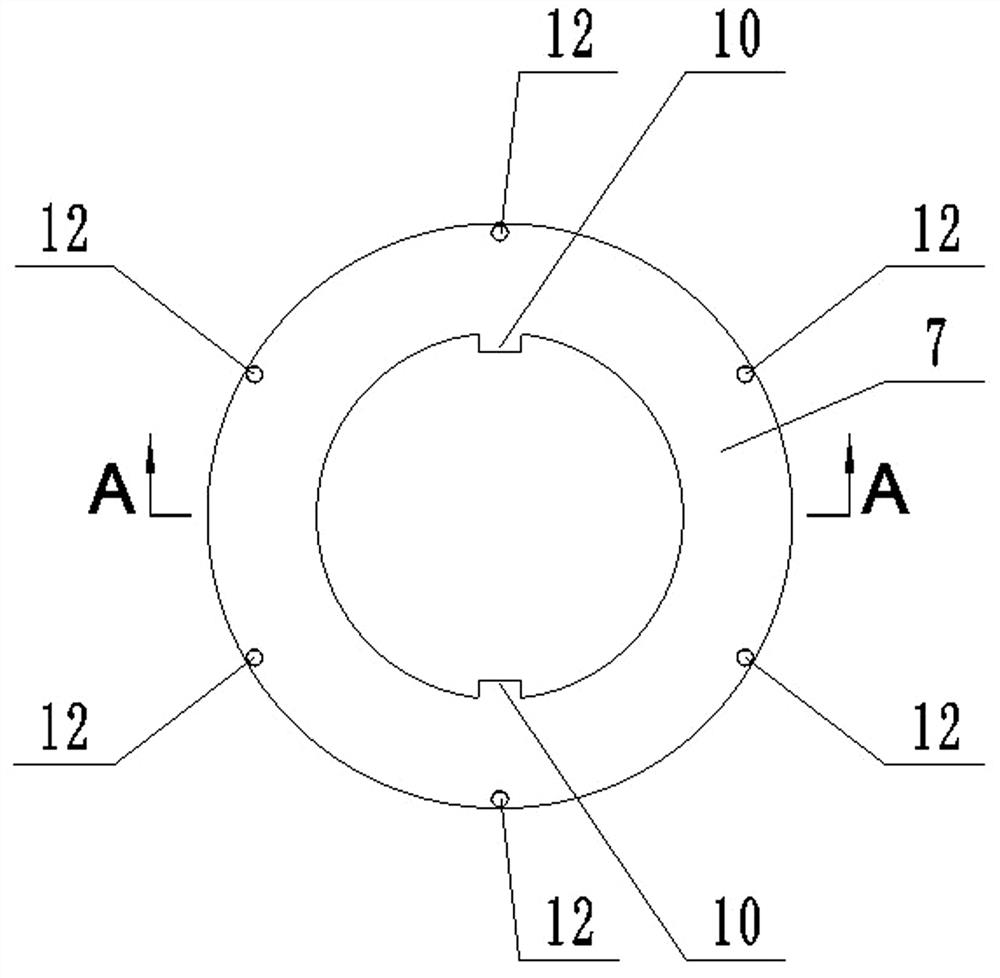

[0021] An ultrasonic horn with a frequency-modulating suction cup includes an ultrasonic horn body 1 and a frequency-modulating sucker; the frequency-modulating sucker includes a cylindrical magnetic sleeve 2, a cylindrical yoke 3, and M arc-groove permanent magnets 4. M arc-groove electromagnets 5, a cylindrical shell 6, an annular top cover 7, and an annular bottom cover 8; M is a positive integer, and M≥2;

[0022] Wherein, the cylindrical section of the ultrasonic horn body 1 faces upward, and the side of the cylindrical section of the ultrasonic horn body 1 is provided with two mutually symmetrical guide grooves 9 along the axial direction; the lower ends of the two guide grooves 9 are closed , the upper end of which passes through the upper end surface of the cylindrical section of the ultrasonic horn body 1;

[0023] The cylindrical magnetic sleeve 2 is coaxially sleeved on the side of the cylindrical section of the ultrasonic horn body 1; the cylindrical yoke 3 is coax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com