Electrode paste assembly

A technology of electrode stickers and components, applied in the field of electrodes, can solve the problems of increasing the reliability of electrical connections, conductive materials cannot guarantee the reliability of electrical connections, etc., and achieve the effect of strong conductive stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the electrode patch assembly of the present application will be described in detail with reference to the accompanying drawings.

[0032] The electrode sticker assembly of the present application includes: a first conductive layer 4 , a second conductive layer 5 , and a substrate layer 6 .

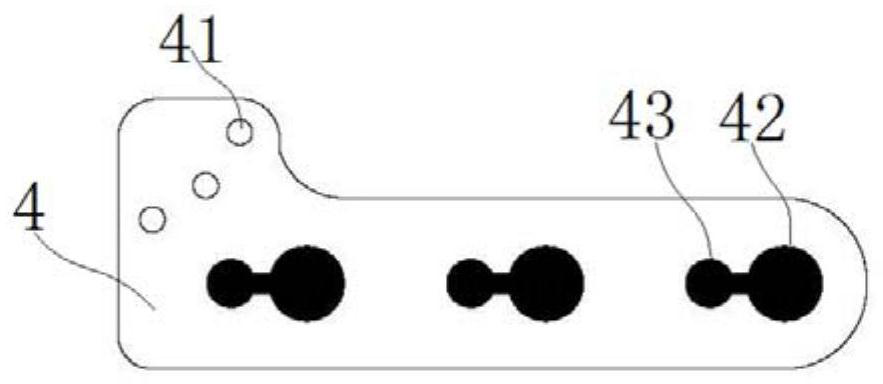

[0033] The first conductive layer 4 is made of a non-conductive material, and its lower side forms a predetermined number of first conductive disk groups, each first conductive disk group includes a first conductive disk 42 and a second conductive disk 43; The first conductive disk 42 and the second conductive disk 43 in a group of conductive disks are electrically connected together; the first conductive layer 4 is also formed with the predetermined number of first through holes 41 .

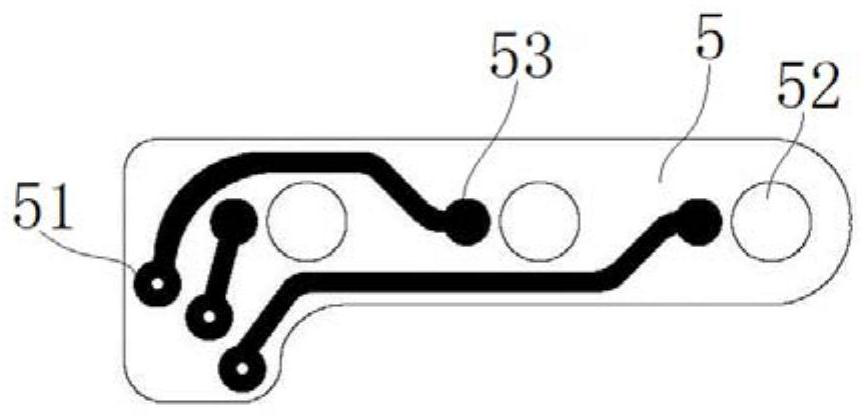

[0034] The second conductive layer 5 is made of non-conductive material, and its upper side forms the predetermined number of second conductive disk groups, each second conductive disk group i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com