Robust material layers

A material layer, insulating material technology, applied in the direction of additive processing of solid materials and liquid materials, additive processing, laying of solid insulation, etc., can solve the problems of cumbersome, unstable connection, not durable, etc. , low noise, small magnetic leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

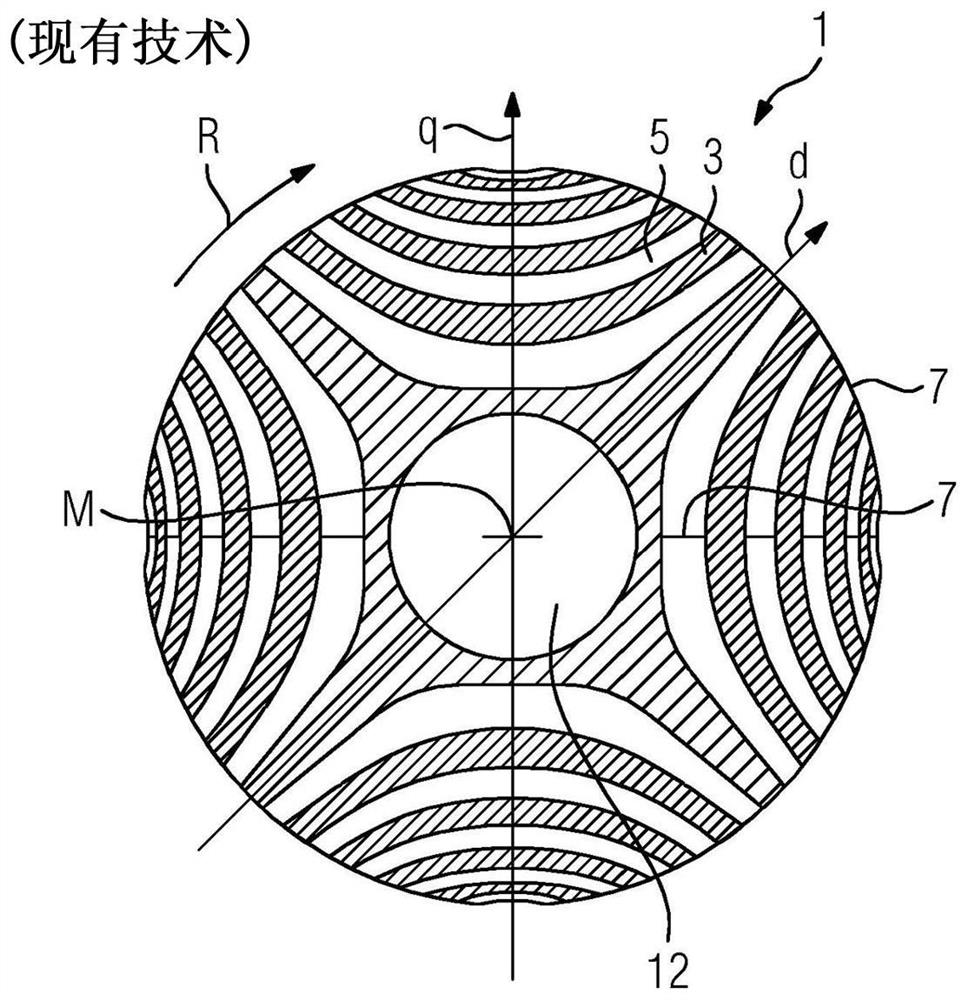

[0104] figure 1 The prior art is shown, namely the laminations of a lamination pack made of soft magnetic material 3 , which also has a magnetic field shielding 5 . The magnetic field shield 5 is stamped from laminations and filled with air or other gas. The figure also shows webs 7 which bring the laminations together and secure them. Furthermore, the figure shows the direction of rotation R, the center point M, the axis q as well as the axis d and the material channel 12 .

[0105] As long as the reference numbers described are present in the exemplary embodiments, they also apply to the subsequent figures and are not described again for reasons of clarity.

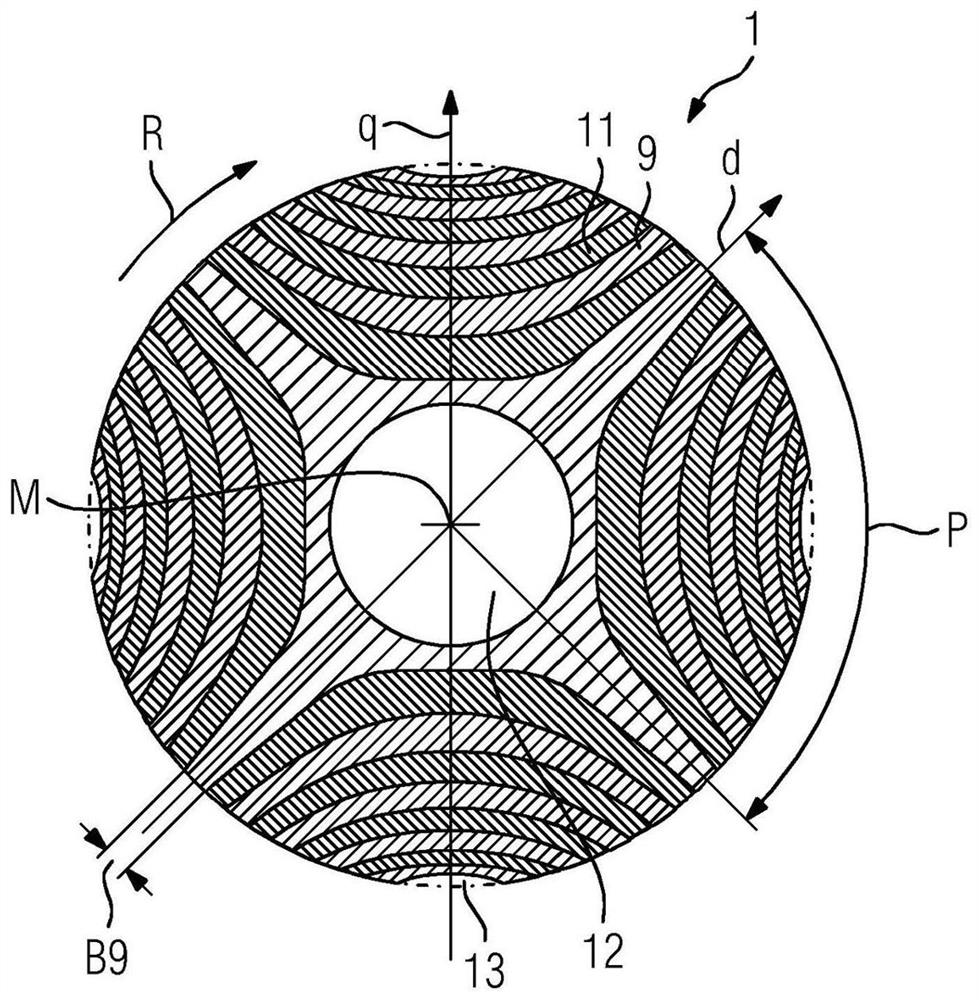

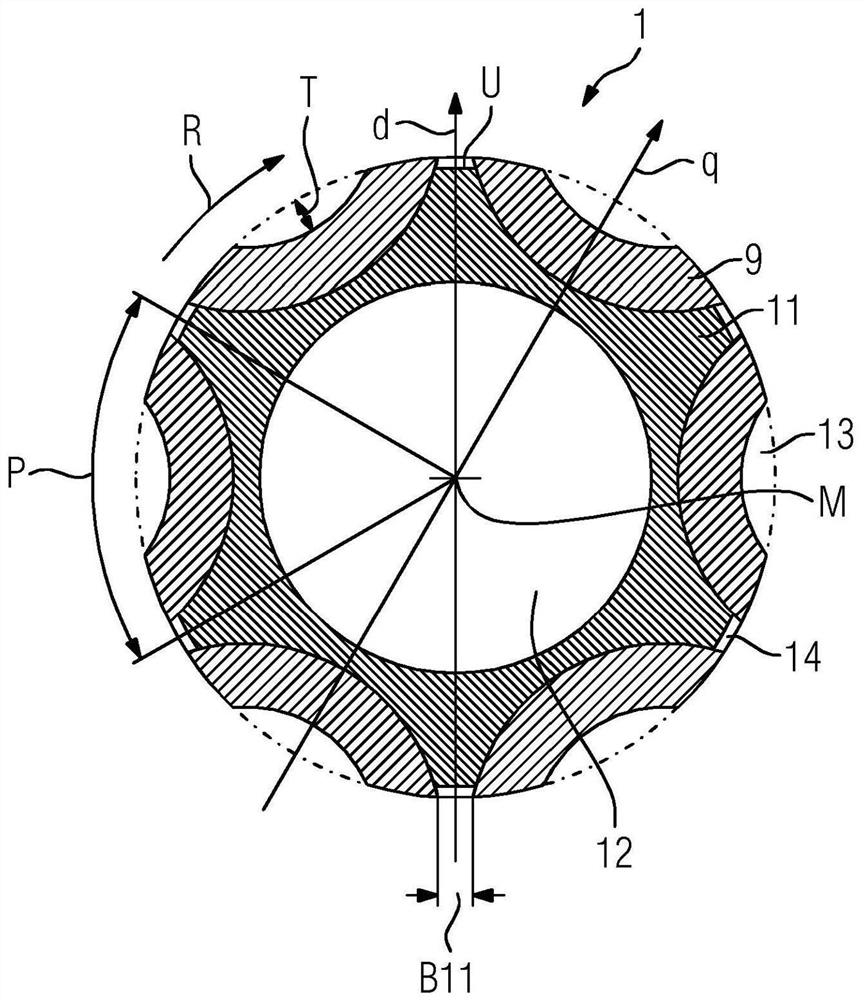

[0106] figure 2 A material layer 1 for a machine, in particular a reluctance machine, is shown. The material layer comprises a magnetic flux guiding region 9 and a magnetic flux blocking region 11 . The magnetic flux guiding region 9 has a magnetic material, in particular a soft magnetic material.

[0107] The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com