Display panel and preparation method thereof

A display panel and via technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of high cost, poor stability and reliability of GSD structure devices, etc., to reduce contact resistance and improve stability performance and reliability, and the effect of improving thermal oxidation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. In the drawings, for clarity and ease of understanding and description, the size and thickness of the components shown in the drawings are not in scale.

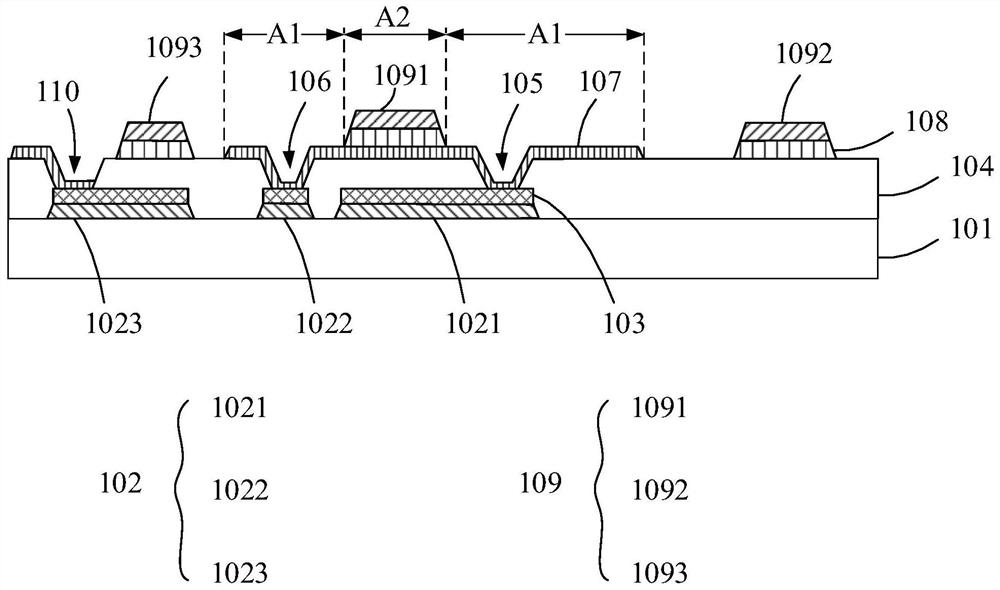

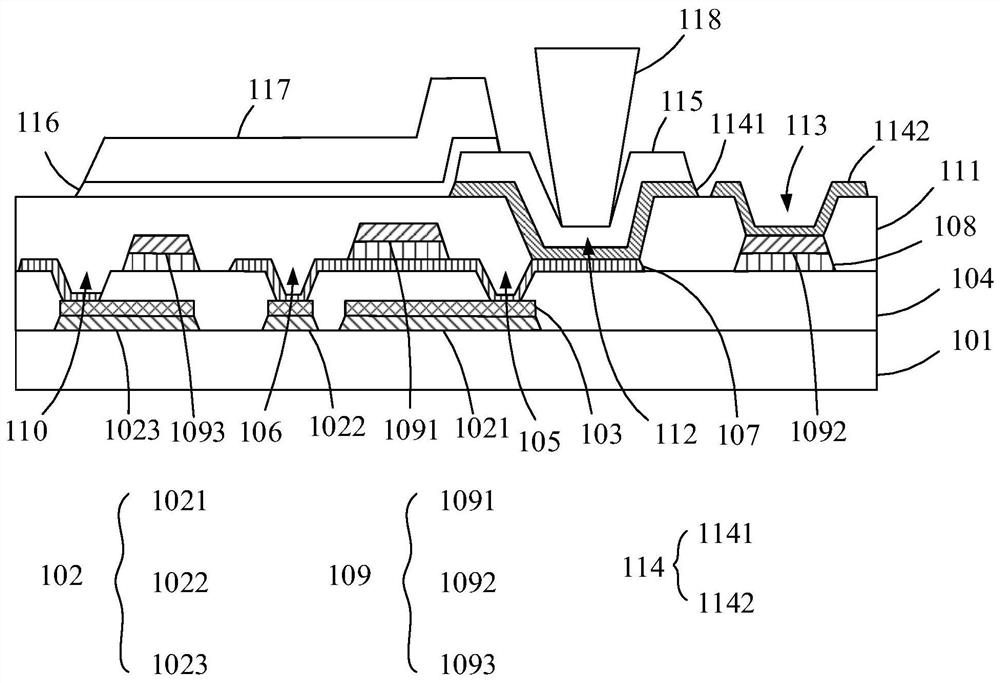

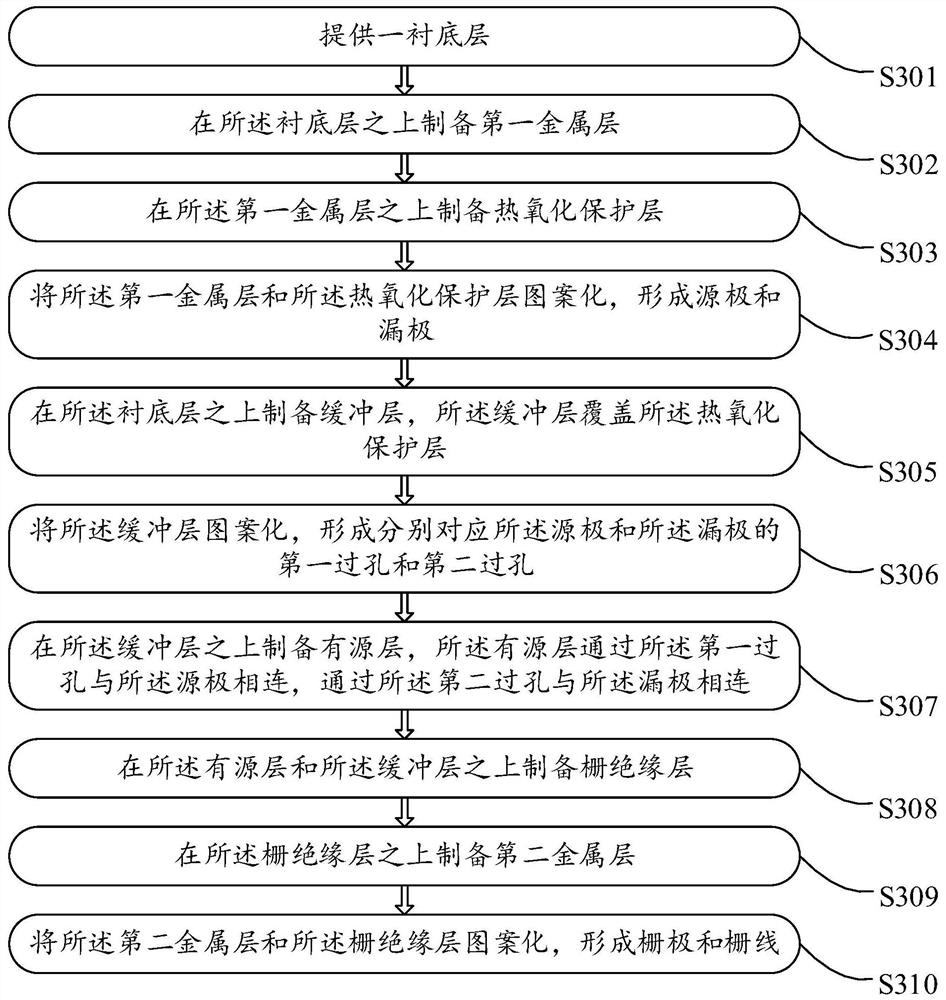

[0021] like figure 1 As shown, in the basic structural diagram of the display panel provided by the embodiment of the present invention, the display panel includes: a substrate layer 101, a first metal layer 102, a thermal oxidation protection layer 103, a buffer layer 104, an active layer 107, a gate an insulating layer 108 , and a second metal layer 109 . The first metal layer 102 is located on the substrate layer 101 and includes a source 1021 and a drain 1022 . The thermal oxidation protection layer 103 is located on the first metal layer 102 . The buffer layer 104 is located on the substrate layer 101 and covers the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com