Solder ball arrangement unit and packaging chip

A technology of solder balls and chips, which is applied in the direction of electrical components, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problems of crosstalk deterioration, shorten the physical distance of the receiving port, expand the chip area, etc., and increase the signal transmission speed , The effect of increased solder ball density and small chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

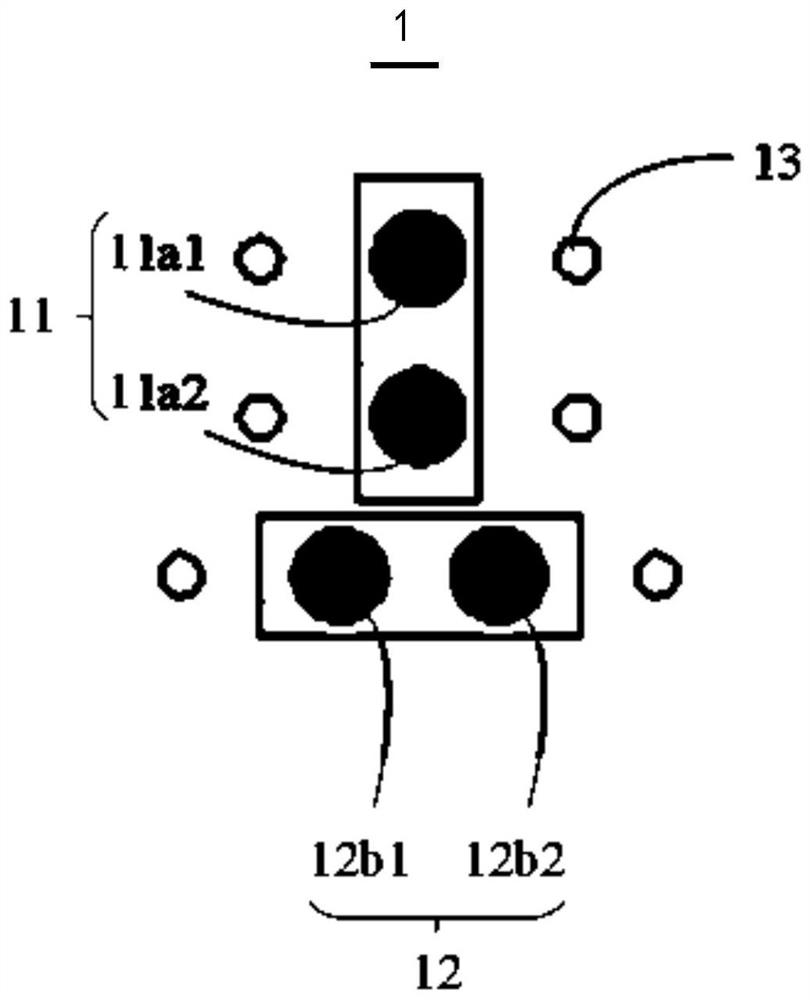

[0038] see image 3 , image 3is a schematic diagram of the first structure of the solder ball arrangement unit in the embodiment of the present invention. The solder ball arrangement unit 1 includes a first signal solder ball pair 11, a second signal solder ball pair 12, and 6 ground solder balls surrounding the first signal solder balls 11a1 and 11a2 and the second signal solder balls 12b1 and 12b2 13. In the embodiment of the present invention, the first pair of signal solder balls 11 and the second pair of signal solder balls 12 are vertically arranged to form an inverted T shape, and six ground solder balls 13 are separately arranged on the first pair of signal solder balls 11 and the second pair of signal solder balls. The two signal solder ball pairs are arranged symmetrically on both sides of the 12 . Specifically, in the vertical first direction, three rows are respectively arranged at intervals, a grounding ball c is symmetrically arranged on both sides of the fir...

Embodiment 2

[0040] see Figure 4 , Figure 4 is a schematic diagram of the second structure of the solder ball arrangement unit in the embodiment of the present invention. The solder ball arrangement unit 1 includes a first signal solder ball pair 11, a second signal solder ball pair 12, and 9 ground solder balls surrounding the first signal solder balls 11a1 and 11a2 and the second signal solder balls 12b1 and 12b2 13. In the embodiment of the present invention, the first pair of signal solder balls 11 and the second pair of signal solder balls 12 are vertically arranged to form an inverted T shape, and nine ground solder balls 13 are separately arranged on the first pair of signal solder balls 11 and the second pair of signal solder balls. Both sides of the two signal solder ball pairs 12 and between the first signal solder ball pair 11 and the second signal solder ball pair 12 are arranged symmetrically. Specifically, in the vertical first direction, a ground solder ball c is symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com