Bismuth oxide/manganese oxide composite supercapacitor and preparation method thereof

A supercapacitor and manganese oxide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as reduction or crystal transformation, unstable structure of bismuth oxide, etc., to improve stability and enhance electrochemical Capacitive properties, effects of increased oxygen vacancies and active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 0.4g of bismuth nitrate, 0.2g of manganese nitrate, and 0.3g of mesoporous silica dissolved in 20ml of absolute ethanol and stir for 3 hours, dry at 30°C for 10h, put the sample into a tube furnace for 3 hours at 500°C for annealing, and then use Wash repeatedly with sodium hydroxide and deionized aqueous solution, centrifuge at last, and dry at 30°C for 10 hours to obtain bismuth oxide / manganese oxide.

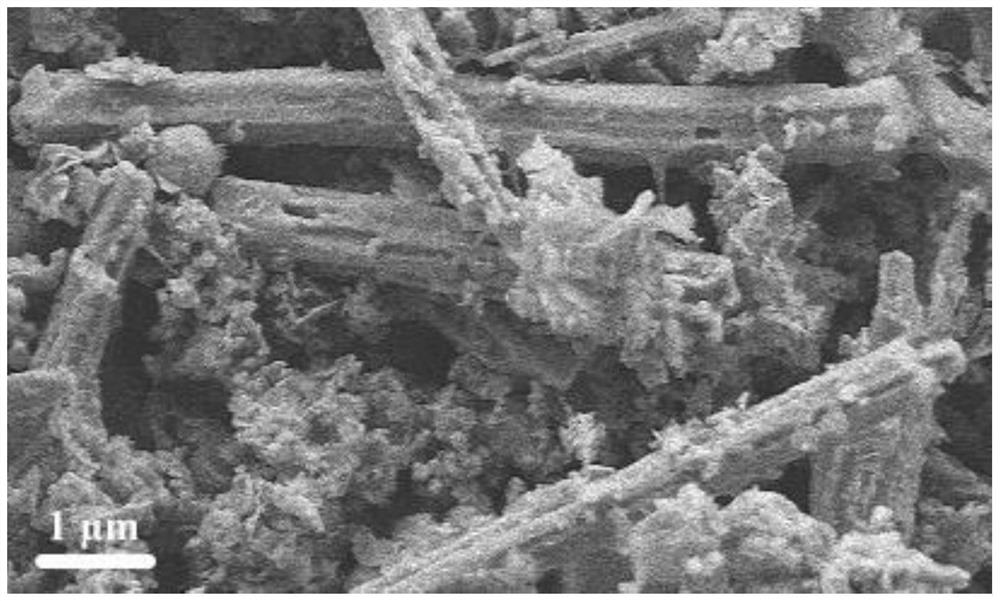

[0031] figure 1 It is a scanning electron microscope image of a bismuth oxide / manganese oxide composite supercapacitor. In the figure, the bismuth oxide with a dendritic structure as the main body is covered by a film-like manganese oxide. The film-like manganese oxide increases the specific surface area of the overall structure and increases a lot The active sites and oxygen vacancies effectively improve the electrochemical capacitive performance of the material.

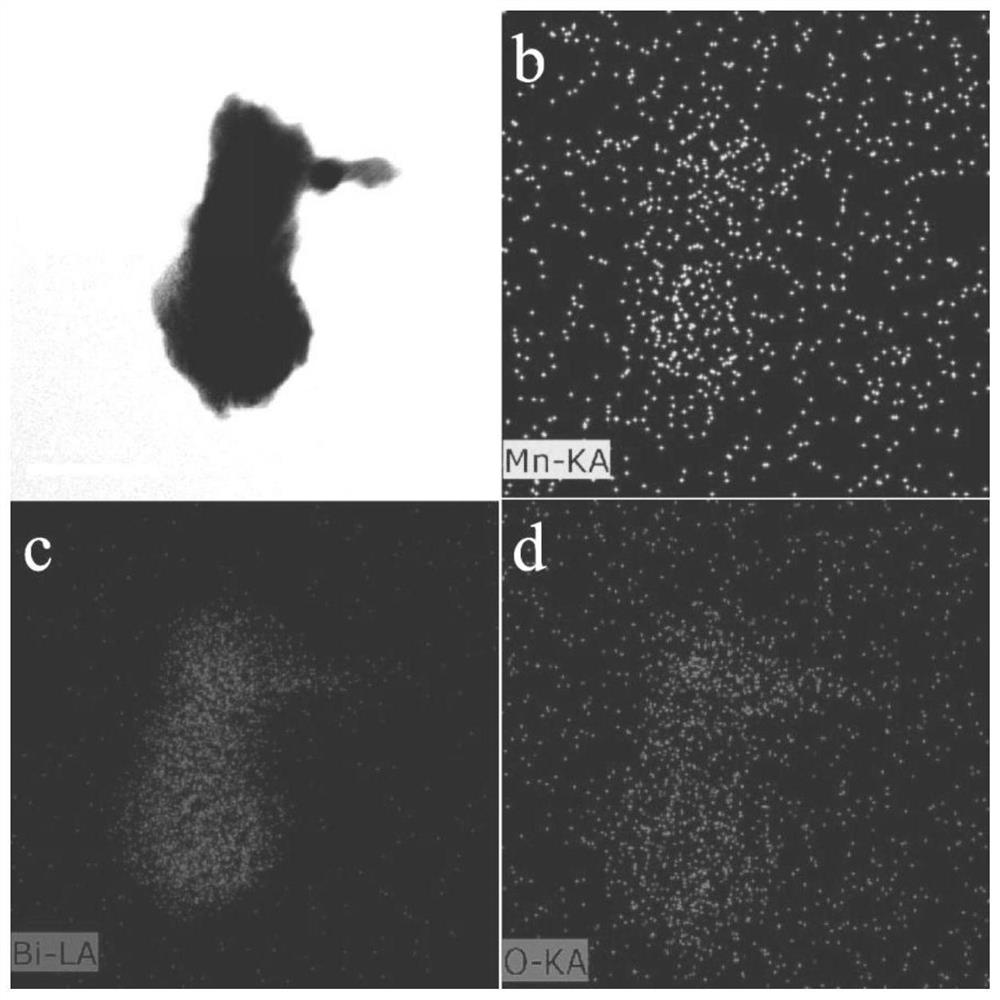

[0032] figure 2 It is the transmission electron microscope (a) and the element distribution m...

Embodiment 2

[0034] Weigh 0.1g of bismuth nitrate, 0.3g of manganese nitrate, 0.1g of mesoporous silica dissolved in 10ml of absolute ethanol and stir for 2 hours, dry at 60°C for 5h, put the sample in a tube furnace for 2 hours at 600°C for annealing, and then use Wash repeatedly with sodium hydroxide and deionized aqueous solution, centrifuge at last, and dry at 60°C for 5 hours to obtain bismuth oxide / manganese oxide.

[0035] image 3 It is the X-ray diffraction pattern of the bismuth oxide / manganese oxide composite supercapacitor, and the test result is consistent with the standard comparison card comparison, indicating that the bismuth oxide and manganese oxide are successfully composited.

[0036] Figure 4 It is the XPS diagram of a bismuth oxide / manganese oxide composite supercapacitor. The full spectrum shows that the composite does contain manganese, oxygen, and bismuth elements. Bi 4f shows two characteristic peaks, which are 4f at 164.1ev 5 / 2 and 4f at 158.8ev 7 / 2 , indicat...

Embodiment 3

[0039] Weigh 1g of bismuth nitrate, 0.5g of manganese nitrate, 1g of mesoporous silica dissolved in 50ml of absolute ethanol and stir for 5 hours, dry at 80°C for 1h, put the sample in a tube furnace for 5 hours at 300°C and anneal for 5 hours, then oxidize with hydrogen Repeated washing with sodium and deionized aqueous solution, centrifugation at last, and drying at 80°C for 1 hour to obtain bismuth oxide / manganese oxide.

[0040] Image 6 It is the cyclic voltammogram of the bismuth oxide / manganese oxide composite supercapacitor, using the composite as the working electrode, the platinum sheet electrode as the counter electrode, and silver / silver chloride as the reference electrode to form a three-electrode system. At 1 mVs in the electrolyte -1 ,10 mV s -1 ,50 mV s -1 ,100 mV s -1All CV curves have a similar shape, and the potential range of the Faraday redox peak is -0.2V to 0.5V. The CV curves shown in the figure have a larger closed area, indicating a higher capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com