Method for realizing dynamic hydraulic optimization of central heating pipe network system

A central heating and system dynamic technology, applied in heating systems, heating methods, household heating, etc., can solve problems such as inability to dynamically adjust, hydraulic imbalance, etc., to achieve easy implementation, small engineering, and reduce power consumption of water pumps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

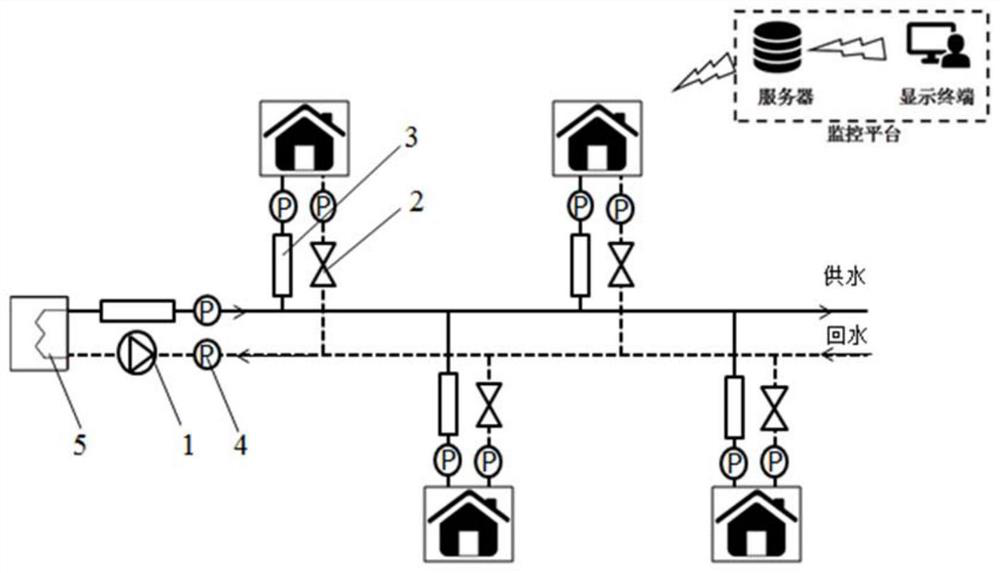

[0061] A method based on a nonlinear programming algorithm to realize the dynamic hydraulic optimization of the central heating pipe network system, in which the structural diagram of the central heating pipe network system is shown in figure 1 , including frequency conversion water pump 1, regulating valve 2, heat meter 3, pressure gauge 4 and boiler / heat exchanger 5.

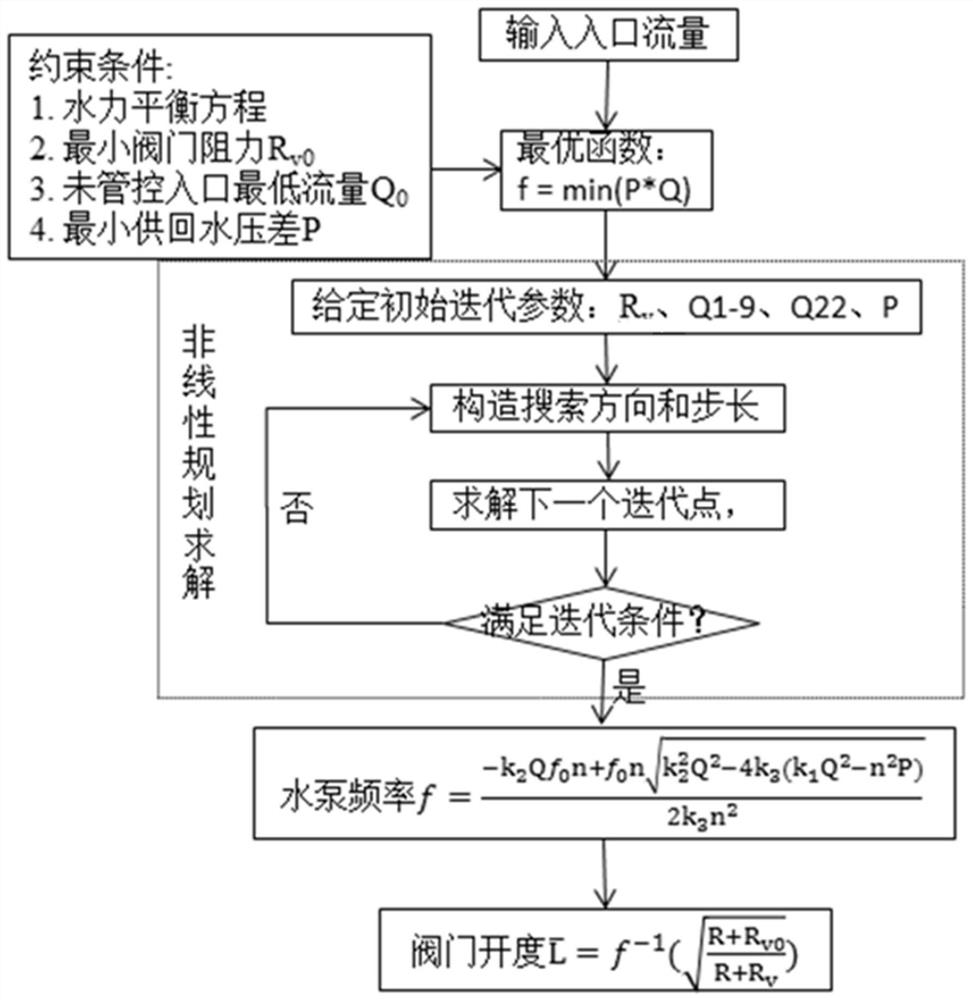

[0062] Through the following four steps, after inputting the given flow rate of each thermal inlet, the frequency of the water pump and the opening of the electric valve can be optimized, and the instructions are sent to each pump and electric valve on the monitoring platform for execution. The specific process is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com