Conveying method for bottom discharge bin pump

A silo pump and ash conveying pipeline technology, which is applied in the field of downdraft silo pump pneumatic conveying, can solve the problems of difficulty in reasonable configuration, clogging of ash conveying pipeline, easy clogging, etc., so as to improve conveying efficiency, reduce unit gas consumption and unit energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

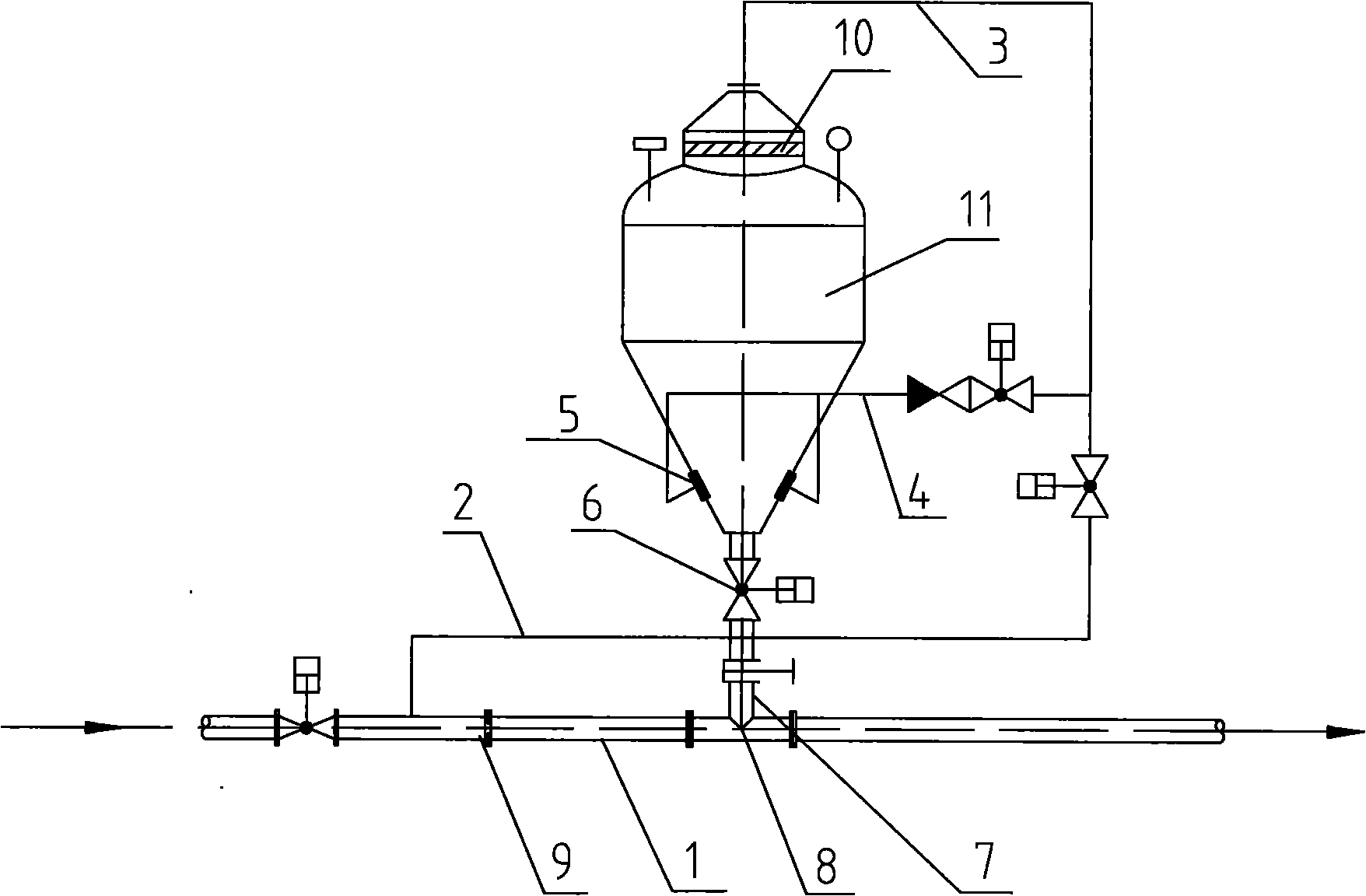

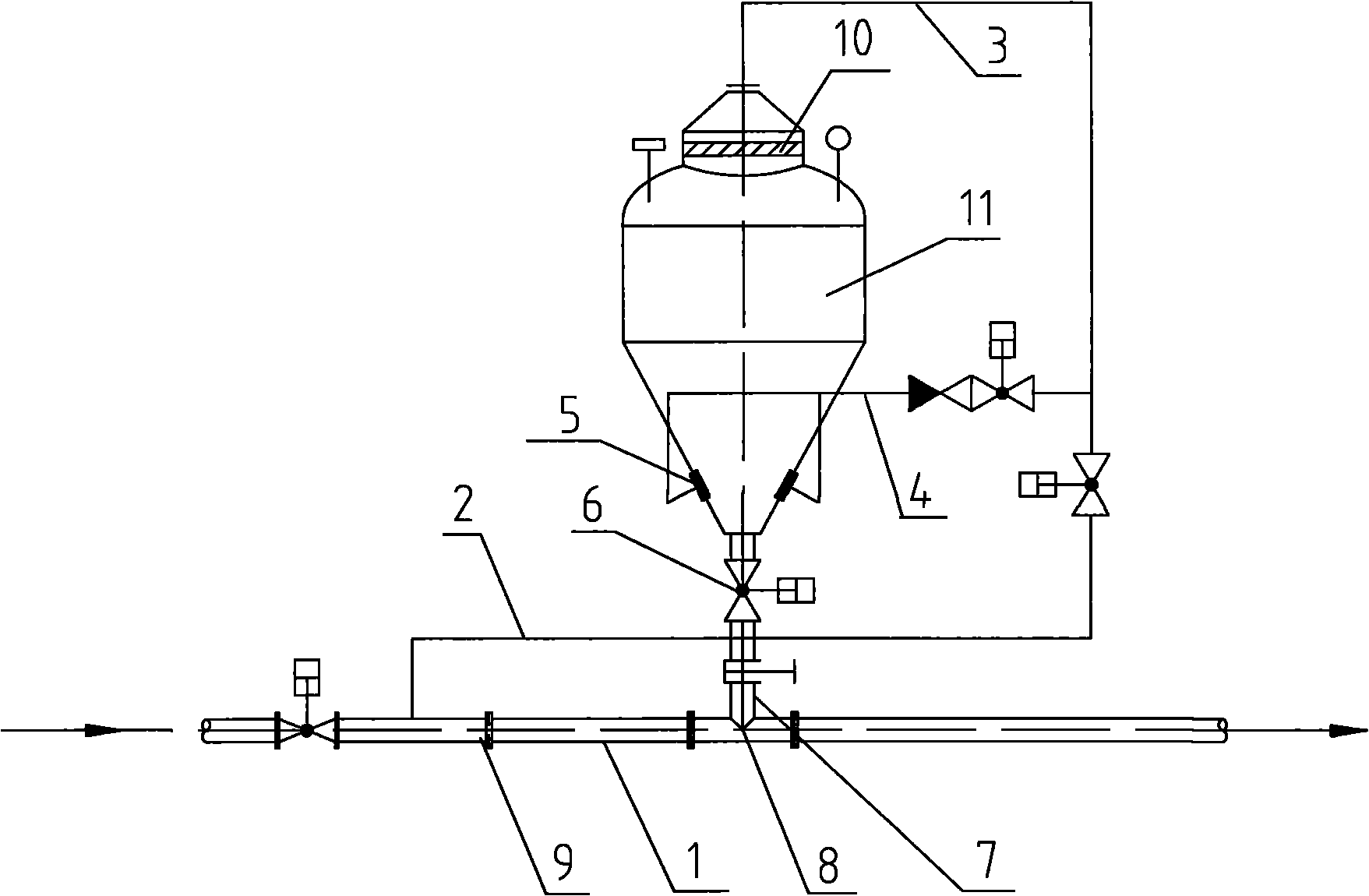

[0019] Below in conjunction with the accompanying drawings, the delivery method of the down-drawing type warehouse pump provided by the invention will be further described in detail:

[0020] The compressed air enters the pressurized fluidization pipeline 2, and pressurizes the warehouse pump 11 through the pressurized pipeline 3; the compressed air enters the fluidization device 5 in the warehouse pump through the fluidization pipeline 4, and performs fluidization treatment on the dry ash in the warehouse pump 11 ; When the pressure in the warehouse pump reaches the preset value, the pneumatic discharge valve 6 is opened, and the dry ash enters the positive pressure ash conveying pipeline 1 through the ash conveying pipeline inlet 8, and the flow regulating device on the positive pressure ash conveying pipeline 1 is adjusted 9. Control the ash output speed of dry ash until the dry ash is conveyed.

[0021] The fluidization device in the warehouse pump is a butterfly gasificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com