Radiation-proof high-flame-retardant special optical cable and preparation method thereof

A radiation-proof and high-flame-retardant technology, applied in the field of optical cables, can solve the problems affecting signal transmission in the radiation area, optical fiber signal polarization, insufficient protection of optical cables, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

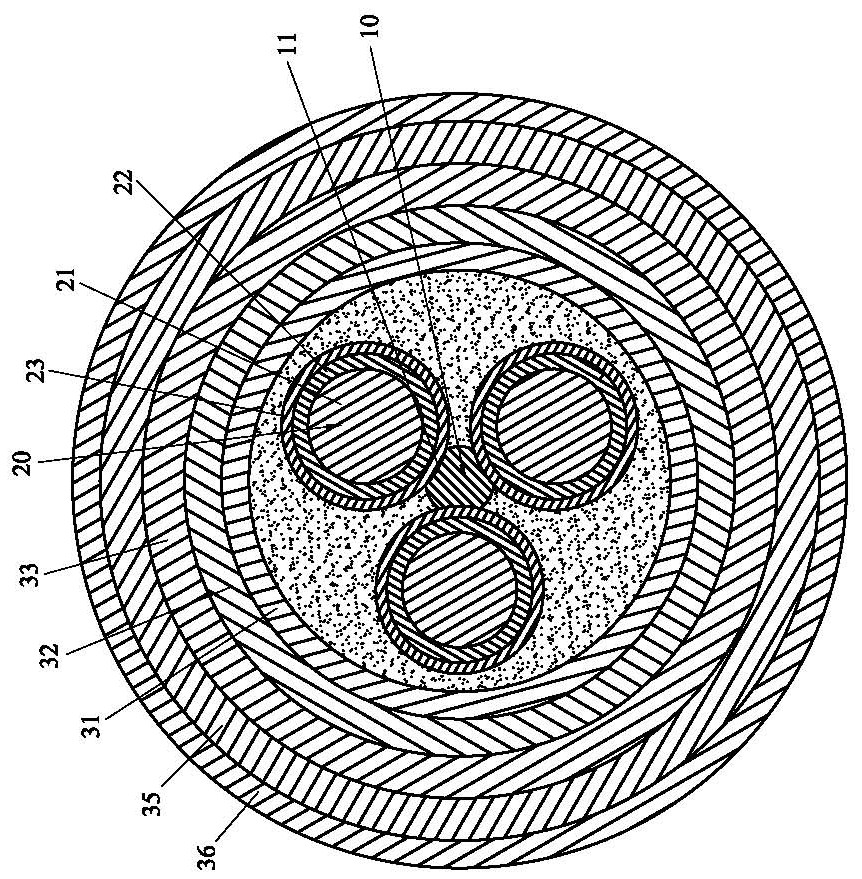

[0032] Please refer to figure 1 As shown, it shows the specific structure of a radiation-proof high flame-retardant special optical cable of a preferred embodiment of the present invention, including an FRP strengthening core 10, a plurality of radiation-proof optical fibers 20, a foam layer 31, a tensile Stretch layer 32, a radiation-proof outer layer 33, a flame-retardant layer 34, a high-temperature-resistant waterproof layer 35 and a wear-resistant layer 36.

[0033] The outer surface of the FRP reinforced core 10 is concavely provided with a plurality of positioning grooves 11, and the plurality of positioning grooves 11 are equally arranged around the axial interval of the FRP reinforced core 10, and each positioning groove 11 is parallel to the axis of the FRP reinforced core 10. Towards.

[0034] The plurality of anti-radiation optical fibers 20 are respectively embedded in corresponding positioning grooves 11 for positioning, and each anti-radiation optical fiber 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap