A handheld concrete roughness three-dimensional detection device and method

A three-dimensional detection and concrete technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the measurement accuracy cannot be well guaranteed, the operation process is cumbersome, etc. The method is convenient, the equipment is portable, and the guarantee is reliable. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

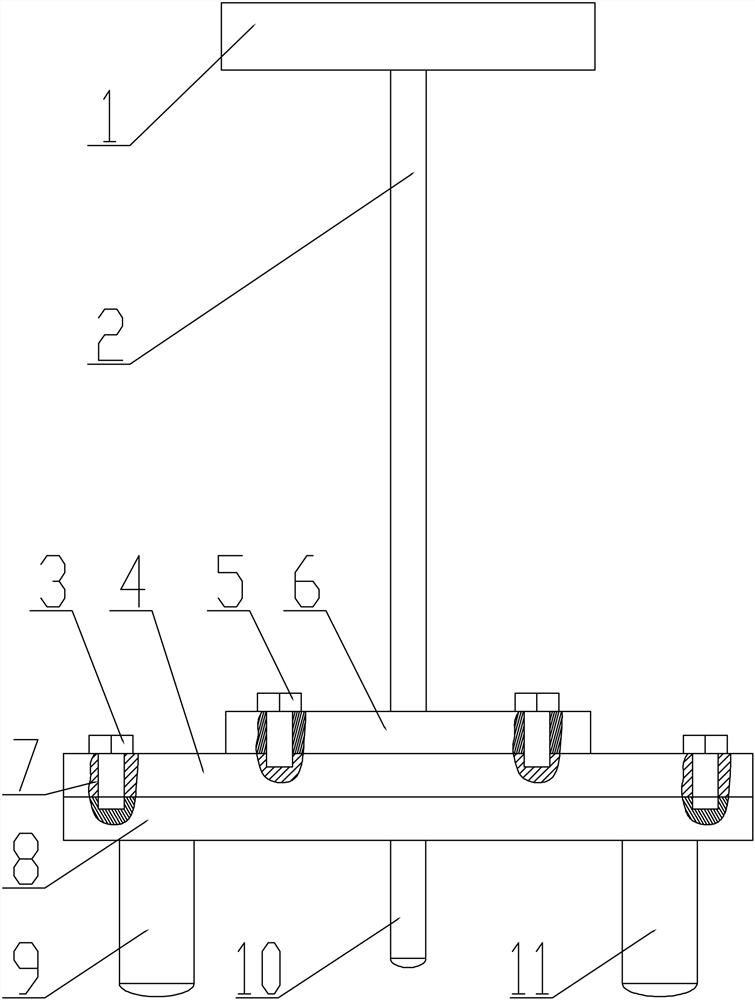

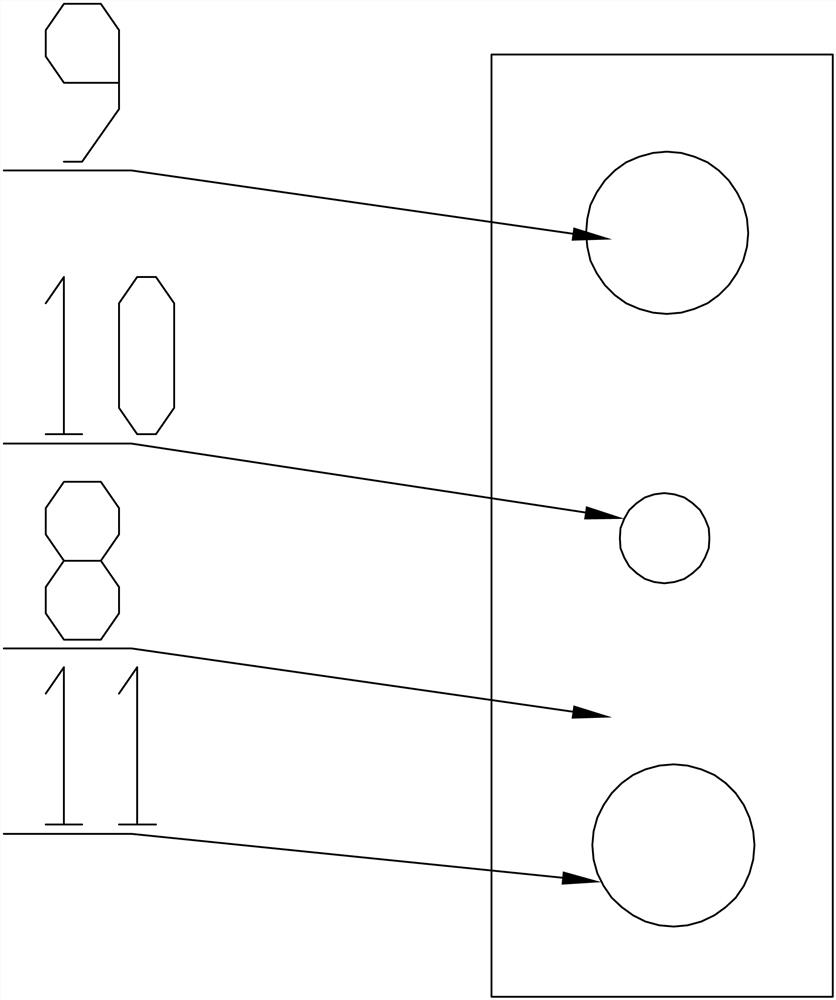

[0030] see Figure 1-3 , a handheld concrete roughness three-dimensional detection device, which includes a camera mounting plate 8, the bottom end of the camera mounting plate 8 is symmetrically fixed with a first camera assembly 9 and a second camera assembly 11, the first camera assembly The laser 10 for positioning is fixed at the position between the camera 9 and the second camera assembly 11, and the camera mounting plate 8 is connected with the hand-held structure through the connecting plate 4; it also includes a calibration plate 12 for positioning the scanning position, the calibration plate 12 cooperates with the first camera assembly 9, the second camera assembly 11 and the laser 10, and realizes the three-dimensional scanning of the concrete surface of the set area. The detection device using the above structure can be used for the roughness detection of the concrete surface. It obtains the three-dimensional point cloud data of the concrete surface, and obtains it...

Embodiment 2

[0036] A method for concrete roughness detection by a handheld concrete roughness three-dimensional detection device, which includes the following steps:

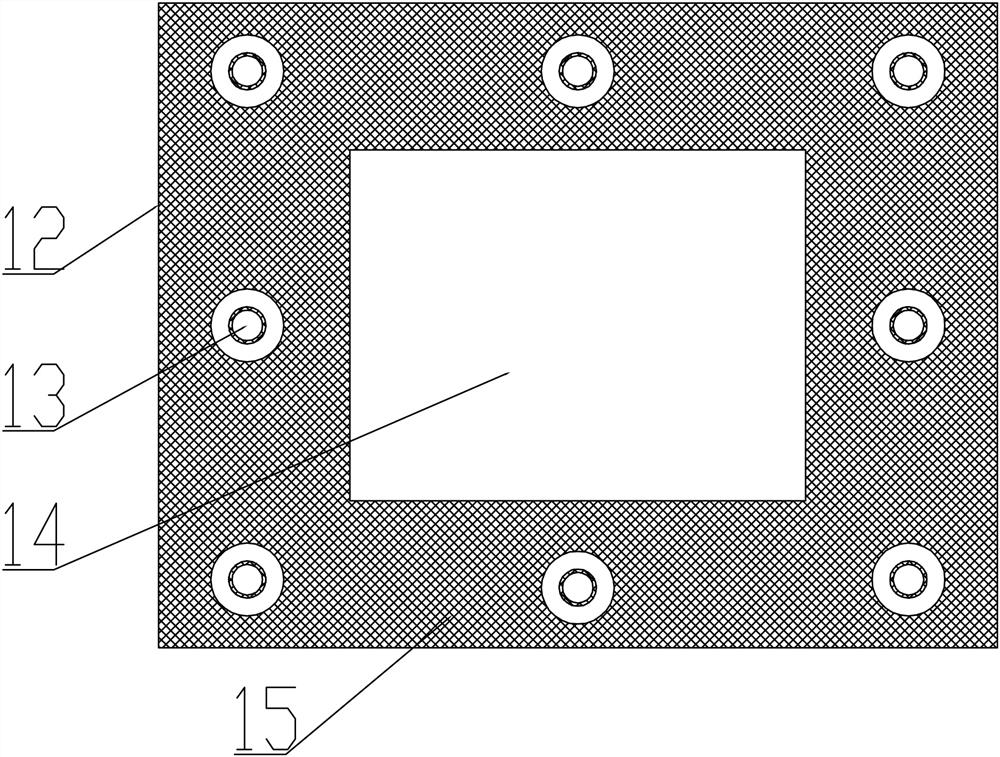

[0037] Step 1: clean up the sundries on the concrete surface to be detected, and select a suitable detection area, place the calibration plate 12 in the selected area, place it flat and fix the calibration plate 12 in the area;

[0038] Step 2: Hold the handle 1, and scan the rectangular area 14 of the calibration plate 12 by moving the above-mentioned detection device to obtain the three-dimensional point cloud data of the concrete surface;

[0039] Step 3: According to the three-dimensional point cloud data, the calculation method of the plane expansion rate is used to calculate the roughness of the point cloud data.

[0040] In the scanning process used in the second step, the point cloud data is acquired by a single-panel scanning method, or the point cloud data is acquired by using the mark points 13 in the calibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com