Automatic shoe sole edge line tracking method based on robot

A technology of automatic tracking and robotics, which is applied in the direction of instruments, image analysis, image enhancement, etc., can solve the problems of unguaranteed product quality, time-consuming and labor-intensive errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

[0045] 1. Camera and robot hand-eye calibration

[0046] The first step of the present invention is camera calibration, and the calibration plate that adopts is circular calibration plate, uses 4x7 altogether 28 circular rings, and ring outer edge diameter is 30mm, and ring inner edge diameter is 1mm, uses Zhang's calibration method to complete camera calibration.

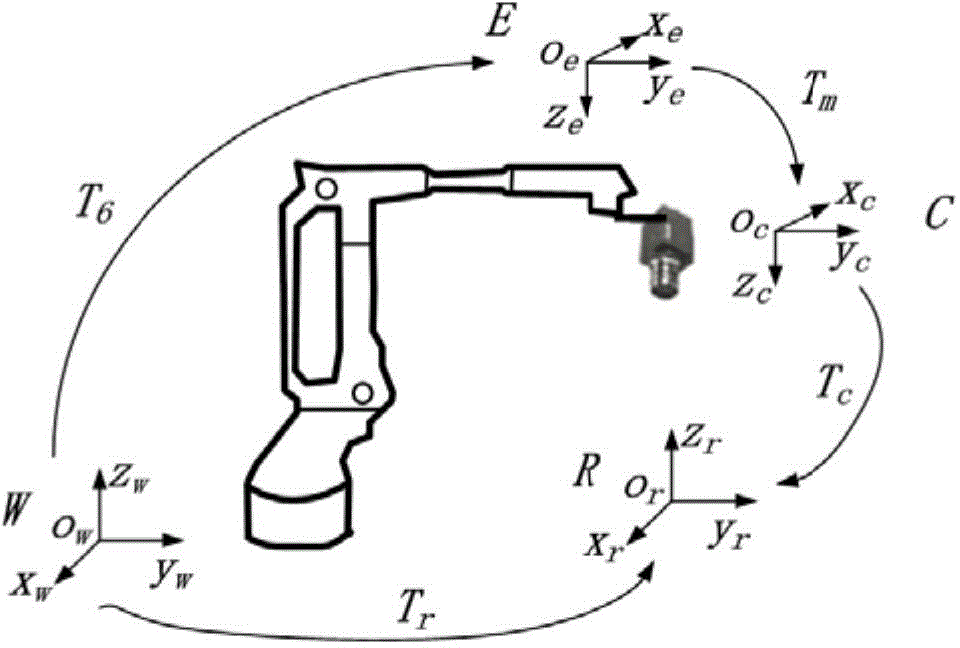

[0047] After the camera is installed on the robot, the coordinate transformation relationship between the camera and the robot is unknown, and it needs to be calibrated through hand-eye calibration, such as figure 1 , it is necessary to solve the fixed transformation relationship between the camera coordinate system and the robot end coordinate system. The solution process is as follows: change the end position and attitude of the robot, obtain a set of calibration target images, and record the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com