Polyester fabric continuous desizing pretreatment method and device

A polyester fabric and desizing technology, which is applied in the processing of textile materials, equipment configuration of textile materials, liquid/gas/steam textile processing, etc. The effect of improving efficiency and increasing practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

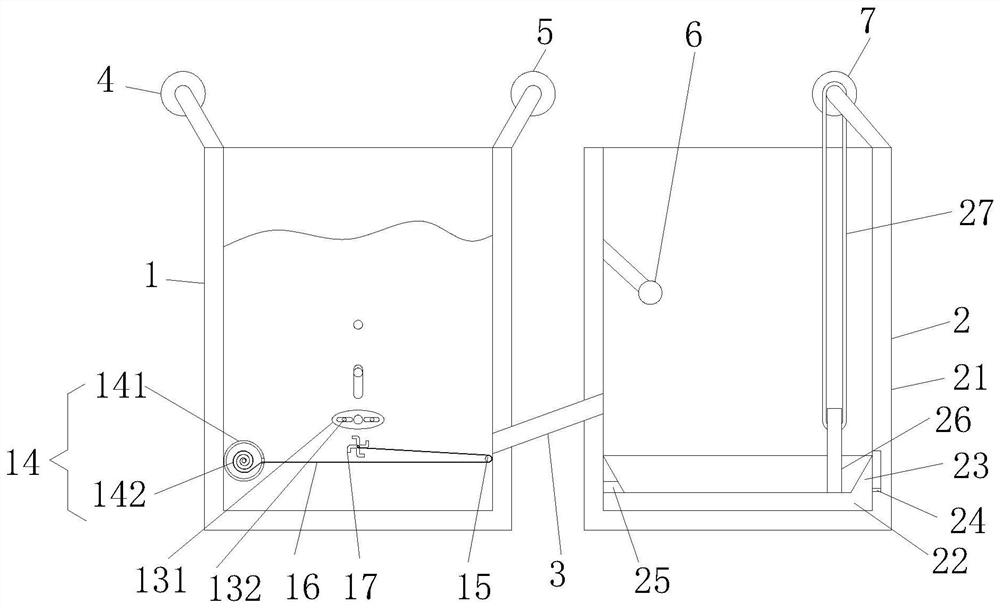

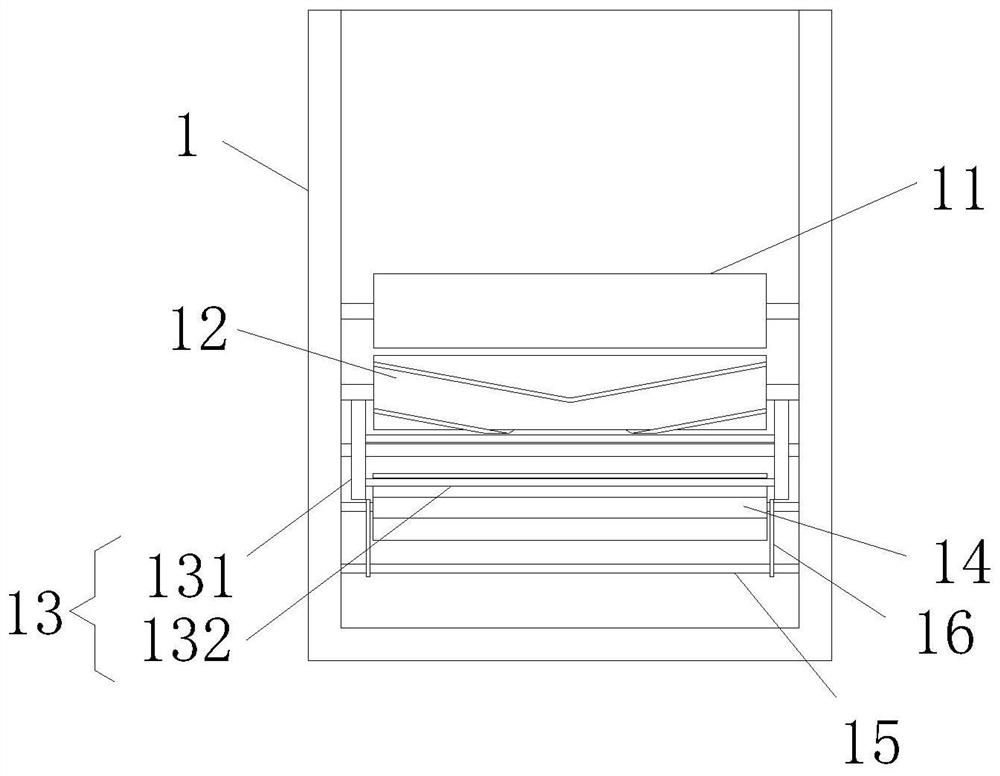

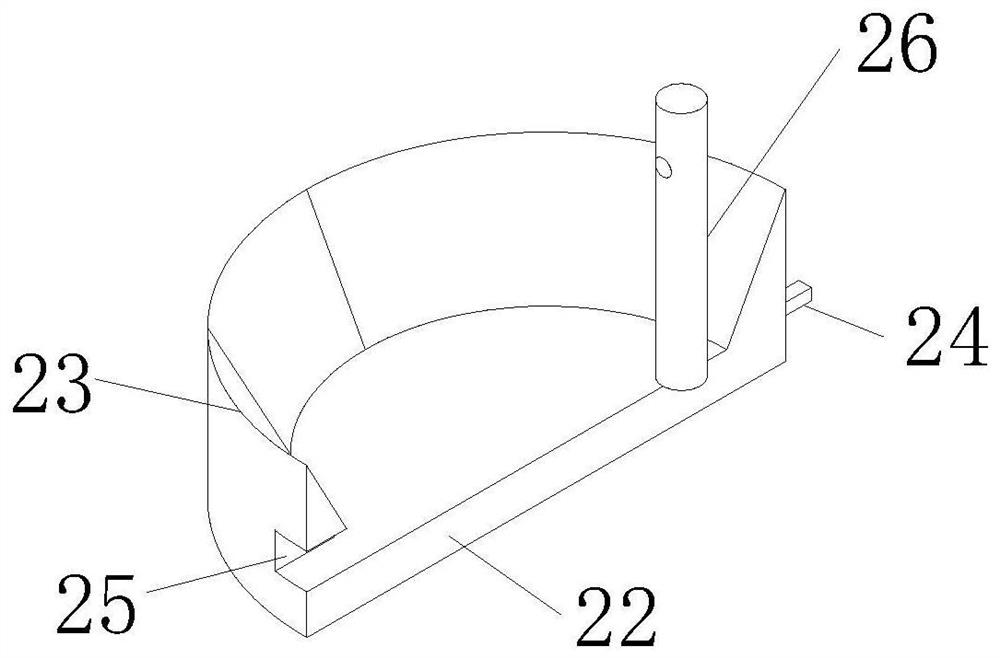

[0022] Embodiment: a kind of polyester fabric continuous desizing pretreatment device, such as Figure 1-Figure 3As shown, it includes a desizing box 1 and a recycling device 2. A connecting pipe 3 is arranged between the desizing box 1 and the recycling device 2, and the desizing box 1 and the recycling device 2 are communicated through the connecting pipe 3. Turning rollers 11 are arranged in the pulp box 1, and the turning rollers 11 are arranged front and rear in the desizing box 1, and a desizing roller 12 is arranged below the turning roller 11, and the desizing rollers 12 are arranged front and back in the desizing box 1, and the turning rollers 11 and the desizing roller 12 are all run through before and after the rotating shaft, and the steering roller 11 and the desizing roller 12 are all flexibly connected between the desizing box 1 through the rotating shaft, and the rotation of the desizing roller 12 on the side wall of the desizing box 1 The position correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com