Tubular plug flow type sodium hypochlorite generator

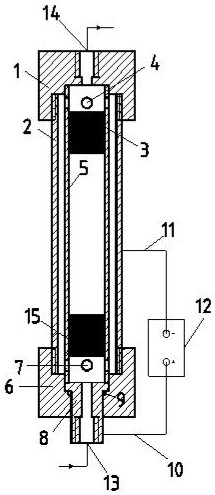

A sodium hypochlorite, plug-flow technology, applied in the field of tubular plug-flow sodium hypochlorite generators, can solve the problems of uneven electrolyte distribution, high equipment purchase costs, and low electrolysis efficiency, and achieve simple structure, low equipment cost, and electrolysis efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The salt water with a concentration of 8 g / L is processed by the system of the present invention. The system is placed vertically, the effective length of the tubular electrode is 1.0 m, and the gap between the tubular cathode and the tubular anode is 4.5 mm. The operating conditions are as follows: the current density is 200 A / m 2 , the inflow flow rate is 6.4 L / h. The operation results are as follows: the current efficiency of the sodium hypochlorite generator is about 76%, the power consumption is about 4.7 kWh / kg available chlorine, the salt consumption is about 3.2 kg sodium chloride / kg available chlorine, and the concentration of available chlorine in the effluent is 2.5 g / L.

Embodiment 2

[0032] The salt water with a concentration of 15 g / L is processed by the system of the present invention. The system is placed horizontally, the effective length of the tubular electrode is 1.0 m, and the gap between the tubular cathode and tubular anode is 4.5 mm. The operating conditions are as follows: the current density is 200A / m 2 , the inflow flow rate is 4 L / h. The operation results are as follows: the current efficiency of the sodium hypochlorite generator is about 82%, the power consumption is about 5 kWh / kg available chlorine, the salt consumption is about 3.5 kg sodium chloride / kg available chlorine, and the concentration of available chlorine in the effluent is 2.3 g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power consumption | aaaaa | aaaaa |

| Power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com