Degerming and anti-fogging glasses wiping liquid and degerming and anti-fogging glasses cloth

A wiping liquid and anti-fog technology, applied in the field of sterilizing and anti-fogging glasses wiping liquid and sterilizing and anti-fogging glasses cloth, can solve the problem that the physical and chemical properties of titanium dioxide are not fully exerted, and the anti-fogging liquid does not use nano-titanium dioxide and anti-fogging liquid preparation. The process is complicated and other problems, to achieve the effect of good anti-fogging effect, easy to use widely, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: A sterilizing and anti-fogging glasses wiping solution prepared from the following raw materials in mass percentage: 70% glycerin, 8% polyethylene glycol octylphenyl ether, 12% nano-titanium dioxide particles, and 10% ethanol.

[0018] The modification method of the inorganic modified nano-titanium dioxide particles is as follows: drop 50 milliliters of saturated hydrochloric acid solution in 1 liter of nano-titanium dioxide aqueous solution prepared by ultrasound, and let it stand for 1 hour; add 20 milliliters of concentrated sulfuric acid solution to the acidic solution of titanium dioxide In the process, add excess sodium hydroxide or ammonia water to maintain the pH value of the system at 8.5-9.5. After the reaction, alumina hydrate is produced, and then the particles of titanium dioxide are evenly wrapped by precipitation.

[0019] A kind of sterilizing and anti-fogging glasses cloth prepared by using the sterilizing and anti-fogging glasses wiping liqui...

experiment example 1

[0020] Experimental example 1: Soak the eyeglass cloth with a wiping solution without ethanol and nano-titanium dioxide to test the non-fogging time, and the non-fogging time can last for 4 hours.

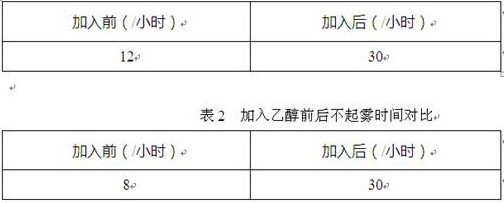

[0021] After adding ethanol first, test and compare the non-fogging time before and after adding inorganic modified nano-titanium dioxide. The comparison results are shown in Table 1. After adding inorganic modified nano-titanium dioxide first, test and compare the non-fogging time before and after adding ethanol. The comparison results are shown in Table 2. The results show that the anti-fogging effect is the best when titanium dioxide and ethanol are present at the same time.

[0022] Table 1 Comparison of non-fogging time before and after adding nano-titanium dioxide

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com