Anti-aging reflective film and preparation method and application thereof

An anti-aging, reflective film technology, used in optics, optical components, radiation-absorbing coatings, etc., can solve the problems of high price and raise the overall manufacturing cost of reflective film, and achieve high cost performance, excellent retroreflective performance, and production costs. falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

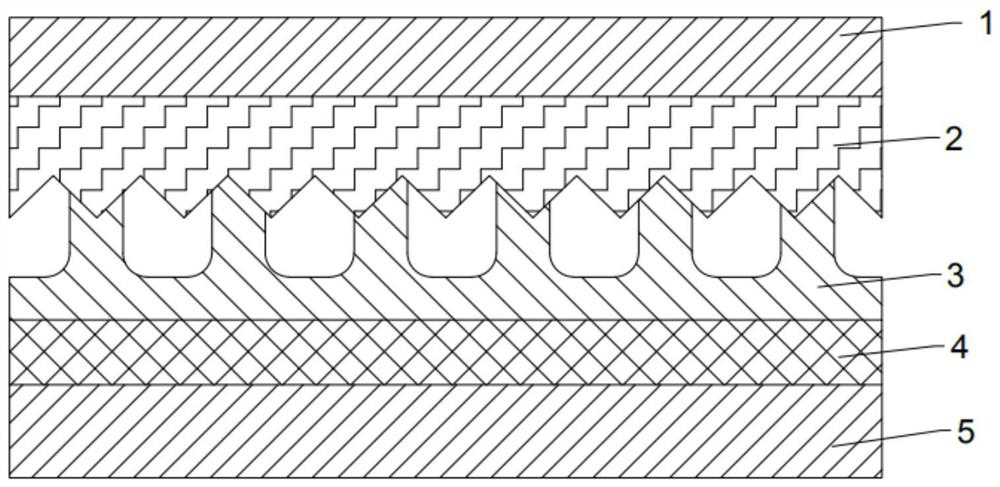

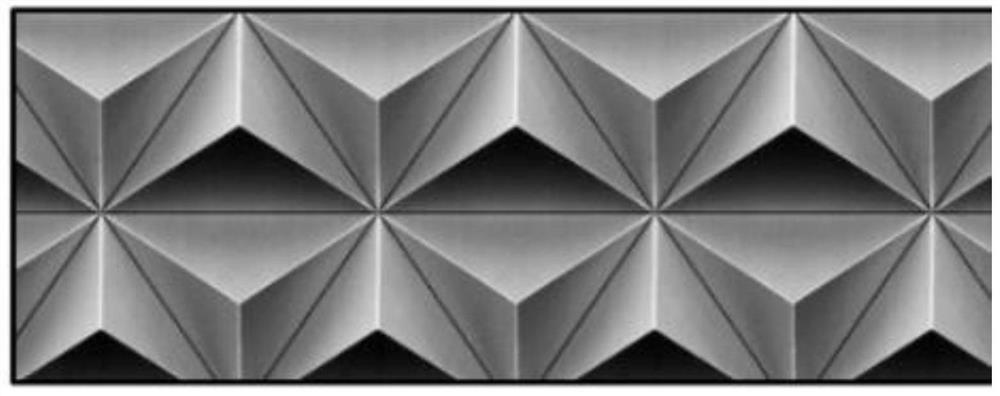

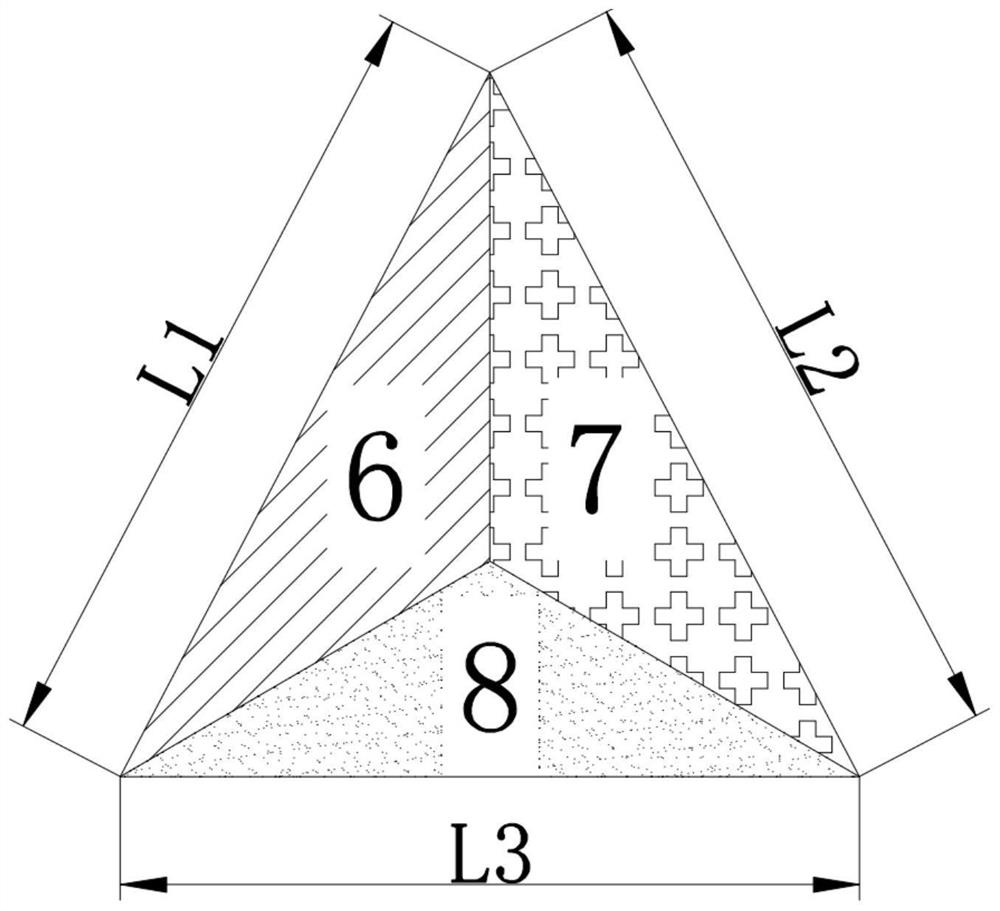

[0027] as attached Figure 1~3 As shown, this embodiment provides a kind of aging-resistant reflective film, which is a microcrystalline cubic structure, specifically an equilateral triangular pyramid structure, the side length of the equilateral triangle at the bottom is L1=L2=L3=110 microns, and the height H=50 microns , The angles between the sides 6, 7, and 8 of the cubic structure and the bottom surface are all 59°, and the angles between the three sides of the triangular pyramid are 90°. The reflective film includes an aging-resistant coating 1 , a prism reflective layer 2 , an air capsule support layer 3 , an adhesive layer 4 and a release layer 5 from outside to inside in sequence.

[0028] Specifically, the preparation method of the reflective film includes the following steps:

[0029] S1, coating acrylic resin coating B on the polyester film A (PET film A) of 50 micron thickness, after oven drying, form aging-resistant coating 1, then carry out winding; Wherein, ac...

Embodiment 2

[0036] as attached Figure 1~3 As shown, this embodiment provides a kind of aging-resistant reflective film, which is a microcrystalline cubic structure, specifically an equilateral triangular pyramid structure, and the side length of the equilateral triangle at the bottom is L1=L2=150 microns, L3=165 microns, height H =72 microns, the side 6 of the cubic structure, the angle between the side 7 and the bottom surface is 59°, the angle between the side 8 and the bottom surface is 54°, and the angle between the three sides of the triangular pyramid is 90°. The reflective film includes an anti-aging coating 1 , a prism reflective layer 2 , an air capsule support layer 3 , an adhesive layer 4 and a release layer 5 from outside to inside in sequence.

[0037] Specifically, the preparation method of the reflective film comprises the following steps:

[0038]S1, coating acrylic resin coating B on the polyester film A (PET film A) of 50 micron thickness, after oven drying, form aging...

Embodiment 3

[0045] This embodiment provides a kind of anti-aging reflective film, and its difference with embodiment 1 is:

[0046] Adopted acrylic resin coating B is mixed by methyl methacrylate 30g, 2-aminoethyl methacrylate 0.5g, ethyl acetate 67.6g, initiator 1.5g, ultraviolet absorber 0.2g, light stabilizer 0.2g And get.

[0047] The adopted air capsule supporting layer 3 is a white polyvinyl chloride film.

[0048] The release layer 5 used is made of glassine release paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com