Starch polymer for preparing tableware and preparation method of starch polymer

A technology of polymer and starch, which is applied in the field of starch polymer and its preparation for the preparation of tableware, can solve the problems of starch with strong water absorption, defects, and inability to maintain a stable state for a long time, and achieve the effect of increasing the degradation rate and improving the heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

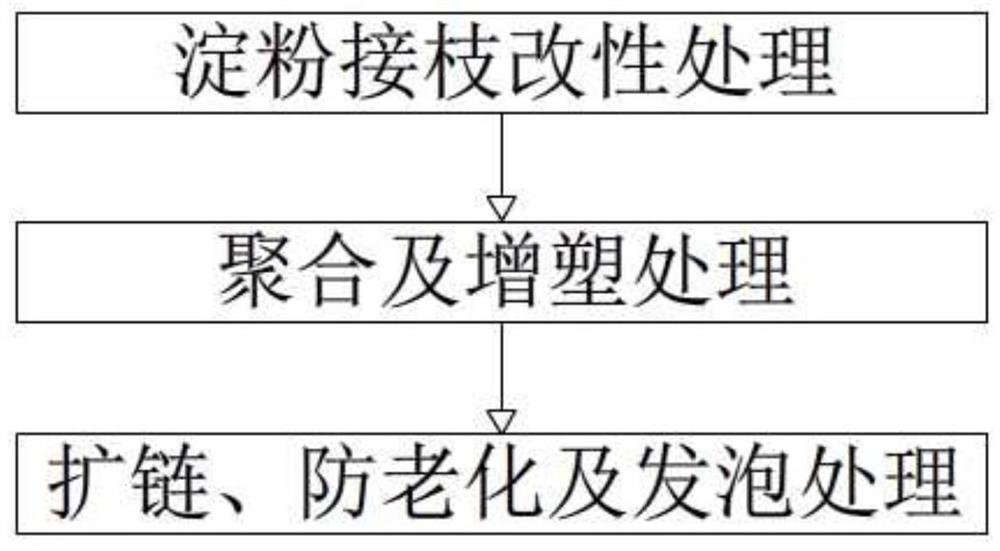

Method used

Image

Examples

Embodiment 1

[0032] The preparation of the starch polymer for preparing tableware comprises the following steps:

[0033] S1: Accurately weigh 60 kg of starch and 60 kg of lactic acid, disperse the starch into tetrahydrofuran, add lactic acid slowly under stirring, mix well, heat up to 60°C for 4 hours, and then filter and remove tetrahydrofuran to obtain surface lactic acid grafting modified starch;

[0034] S2: The surface lactic acid grafted modified starch prepared in S1 was vacuum-dried at 50° C. for 24 hours to obtain a dry surface lactic acid grafted modified starch;

[0035] S3: Accurately weigh 20 kg of polyvinyl alcohol, 10 kg of polybutylene succinate, 3 kg of dioctyl phthalate as a plasticizer and 3 kg of stannous chloride as a catalyst and dry The surface lactic acid grafted modified starch was mixed, and then stirred and reacted for 15 hours at a temperature of 140 ° C and a pressure of 0.05 MPa;

[0036] S4: Accurately weigh 10 kg of cellulose acetate propionate as an adhe...

Embodiment 2

[0039] The preparation of the starch polymer for preparing tableware comprises the following steps:

[0040] S1: Accurately weigh 70 kg of starch and 70 kg of lactic acid, disperse the starch into tetrahydrofuran, add lactic acid slowly under stirring, mix well, heat up to 70°C for 5 hours, and then filter and remove tetrahydrofuran to obtain surface lactic acid grafting modified starch;

[0041] S2: vacuum-dry the surface lactic acid grafted modified starch prepared in S1 for 30 hours at 60° C. to obtain dry surface lactic acid grafted modified starch;

[0042] S3: Accurately weigh 30 kg of polyvinyl alcohol, 15 kg of polybutylene succinate, 4 kg of dioctyl terephthalate as a plasticizer and 4 kg of stannous octoate as a catalyst and dry The surface lactic acid grafted modified starch was mixed, and then stirred and reacted for 16 hours at a temperature of 150°C and a pressure of 0.08MPa;

[0043]S4: Accurately weigh 15 kg of cellulose acetate succinate as an adhesion enhan...

Embodiment 3

[0046] The preparation of the starch polymer for preparing tableware comprises the following steps:

[0047] S1: Accurately weigh 80 kg of starch and 80 kg of lactic acid, disperse the starch into tetrahydrofuran, slowly add lactic acid under stirring, mix well, heat up to 80°C for 6 hours, and then filter and remove tetrahydrofuran to obtain surface lactic acid grafting modified starch;

[0048] S2: The surface lactic acid grafted modified starch prepared in S1 was vacuum-dried at 70° C. for 36 hours to obtain a dry surface lactic acid grafted modified starch;

[0049] S3: Accurately weigh 40 kg of polyvinyl alcohol, 20 kg of polybutylene succinate, 5 kg of dibutyl phthalate as a plasticizer and 5 kg of a mixture of stannous chloride and stannous octoate as a catalyst Mix with the dry surface lactic acid grafted modified starch prepared in S2, and then stir and react for 18 hours under the conditions of a temperature of 160°C and a pressure of 0.1MPa; in specific implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com