Efficient aluminum removing agent for alkali recovery and using method thereof

A kind of aluminum remover, high-efficiency technology, applied in chemical instruments and methods, metallurgical wastewater treatment, special compound water treatment, etc. The effect of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

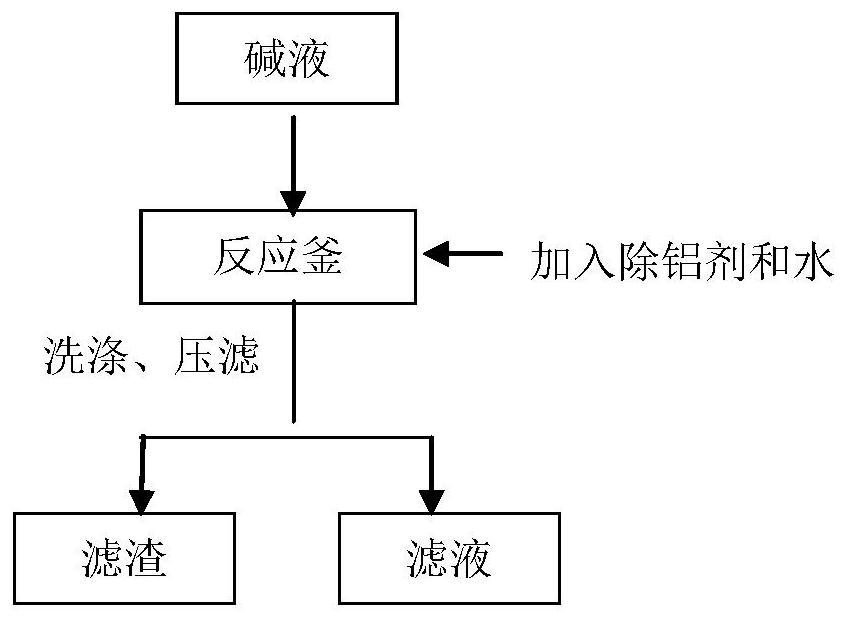

Method used

Image

Examples

Embodiment 1

[0029] Measure the demoulding waste caustic lye of a certain mold repairing factory of 1L, after detecting aluminum ion content is 135g / L, and alkalinity is 137g / L, handles this waste caustic according to process of the present invention, and process is as follows:

[0030] Add 472.5g of aluminum removal agent and 1L of water, stir well, monitor the temperature, the temperature begins to drop after 52 minutes of reaction, and the reaction is completed. The lye was separated from the calcium aluminate by pressure filtration, and the filter residue was washed with 250 ml of water. After testing, the volume of lye after treatment is 1.2L, the concentration of aluminum ions is 9.4g / L, the removal rate of aluminum ions is 93%, and the alkalinity is 121g / L, which can meet the demoulding conditions without adding sodium hydroxide.

Embodiment 2

[0032] Measure the demoulding waste lye of 1L certain aluminum profile factory, after testing aluminum ion content is 104g / L, and alkalinity is 122g / L, handles this waste lye according to process of the present invention, and process is as follows:

[0033] Add 312g of aluminum removal agent and 1L of water, stir well, monitor the temperature, the temperature begins to drop after 40 minutes of reaction, and the reaction is completed, separate the lye from the calcium aluminate by pressure filtration, and wash the filter residue with 250ml of water. After testing, the volume of lye after treatment is 1.4L, the concentration of aluminum ions is 6.1g / L, the removal rate of aluminum ions is 94%, and the alkalinity is 89g / L. Sodium hydroxide can be added appropriately to meet the concentration required for production.

Embodiment 3

[0035] Measure the alkaline etching solution of a certain aluminum alloy surface treatment plant in 1L, after testing, the aluminum ion content is 32g / L, and the alkalinity is 64g / L. According to the process of the present invention, the spent alkaline solution is processed, and the process is as follows:

[0036] Add 128g of aluminum removal agent and 1L of water, stir well, monitor the temperature, the temperature begins to drop after 36 minutes of reaction, and the reaction is completed, separate the lye from the calcium aluminate by pressure filtration, and wash the filter residue with 250ml of water. After testing, the volume of lye after treatment is 1.5L, the concentration of aluminum ions is 2.9g / L, the removal rate of aluminum ions is 91%, and the alkalinity is 59g / L. The surface treatment of aluminum profiles can be carried out without adding sodium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com