Novel efficient green printing equipment

A kind of printing equipment and high-efficiency technology, applied in the field of new high-efficiency green printing equipment, can solve the problems of labor-intensive, low-efficiency green printing, manual replacement of printed items, etc., and achieve the effect of improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

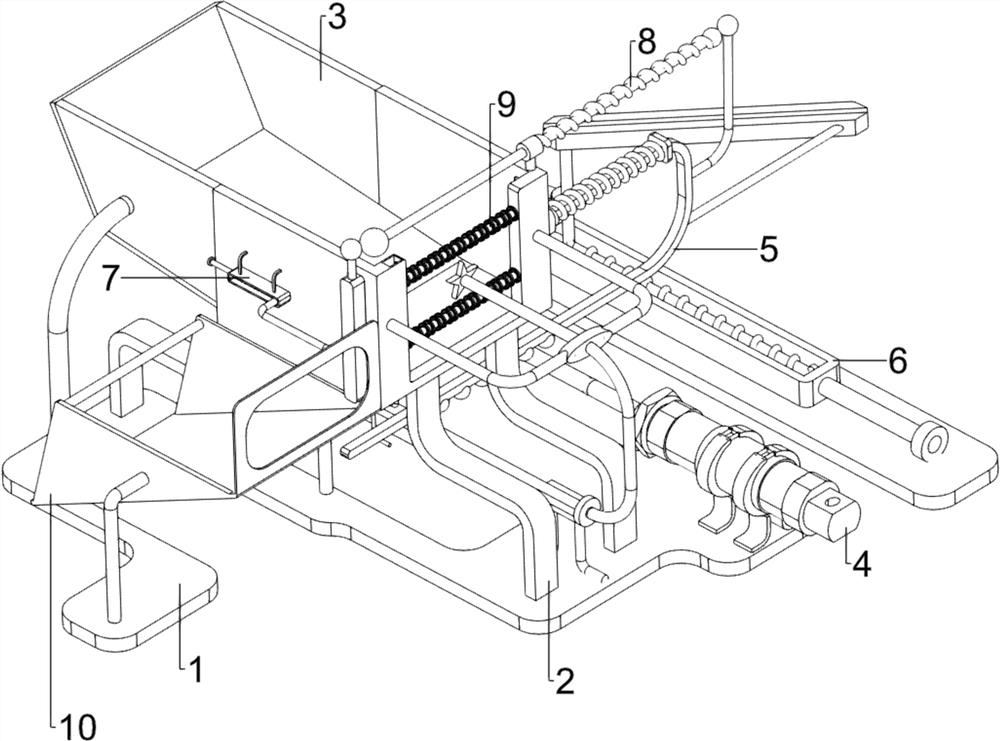

[0060] A new type of high-efficiency green printing equipment, such as figure 1 As shown, it includes a base plate 1, a first support seat 2, a discharge frame 3, a stamping mechanism 4 and a material pushing mechanism 5, the top of the base plate 1 is symmetrically provided with the first support seat 2 on the front and rear sides, and the first support seats 2 on the front and rear sides are symmetrical. A discharge frame 3 is connected between the support bases 2, and a stamping mechanism 4 is provided on the top front side of the bottom plate 1. The stamping mechanism 4 contacts and cooperates with the front side of the discharge frame 3, and the front side of the discharge frame 3 is slidingly provided with a pusher. Agency 5.

[0061]When the worker needs to carry out green printing on the item, the worker needs to put the item into the discharge frame 3 first, because the rear side of the discharge frame 3 is inclined, and the items on the rear side of the discharge fra...

Embodiment 2

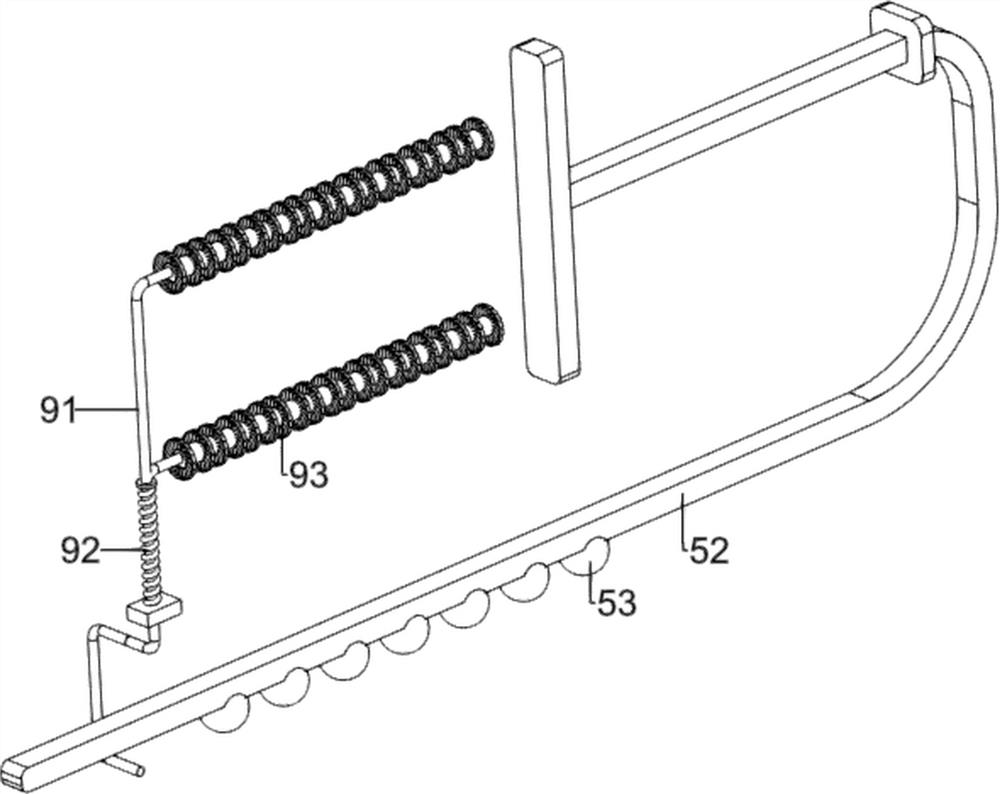

[0063] In a preferred embodiment of the present invention, as figure 2 As shown, the stamping mechanism 4 includes a second support seat 41, a cylinder 42, a first push rod 43, a third support seat 44, a second push rod 45, a first support slide bar 46 and a stamp 47. The bottom plate 1 top The front side is provided with a second support seat 41, and a cylinder 42 is placed in the second support seat 41. The end of the telescopic rod of the cylinder 42 is fixedly connected with a first push rod 43, and a third support seat is installed on the left side of the top front side of the bottom plate 1. 44. The second push rod 45 is slidingly provided in the third support seat 44, the rear end of the first push rod 43 is connected to the middle part of the rear side of the second push rod 45, and the first support slide is connected between the front sides of the discharge frame 3. Rod 46, the front side sliding type of the second push rod 45 is located in the first support slide r...

Embodiment 3

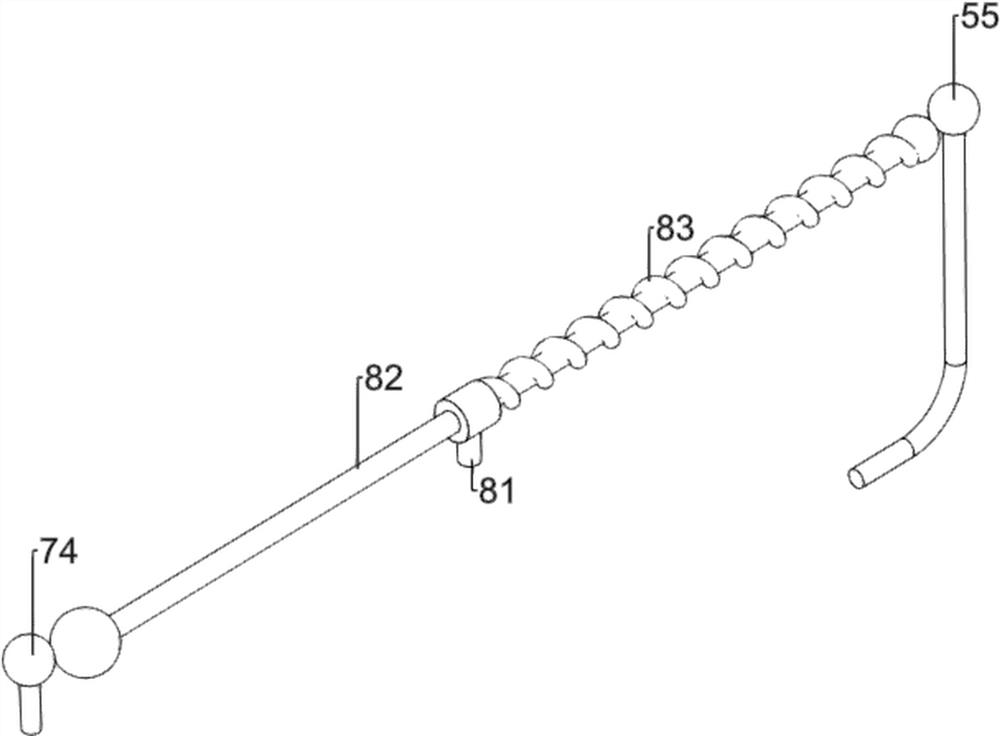

[0066] In a preferred embodiment of the present invention, as figure 1 and Figure 3-Figure 8 As shown, the pusher mechanism 5 includes a fourth support seat 51, a first push block 52, a small iron ball 53, a first spring 54, a first club 55 and a first long iron bar 56, and the discharge frame 3 right The front part of the side is fixedly connected with a fourth support seat 51, and the fourth support seat 51 is provided with a first push block 52 in a sliding manner, and the lower part of the first push block 52 is welded with small iron balls 53 at intervals, and the first push block 52 is sleeved with The first spring 54, the two ends of the first spring 54 are respectively connected on the fourth supporting seat 51 and the first pushing block 52, the first ball rod 55 is welded on the upper right end of the first pushing block 52, the lower part of the right end of the first pushing block 52 A first long iron bar 56 is provided.

[0067] When the first printed item on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com