Jaw crusher for engineering and using method

A jaw crusher and engineering technology, applied in chemical instruments and methods, cleaning methods and appliances, magnetic separation, etc., can solve problems such as blockage of iron removal channels, iron choking in crushers, and impact on equipment iron removal processes, etc., to achieve guaranteed The effect of sealing, convenient collection and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

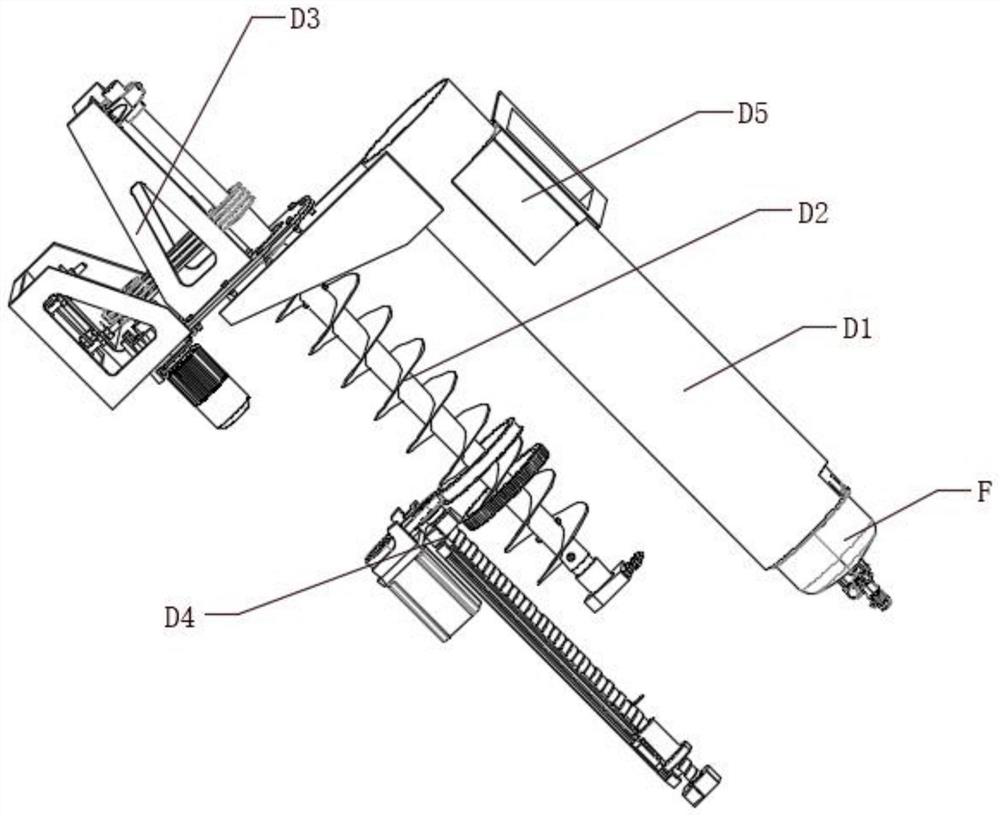

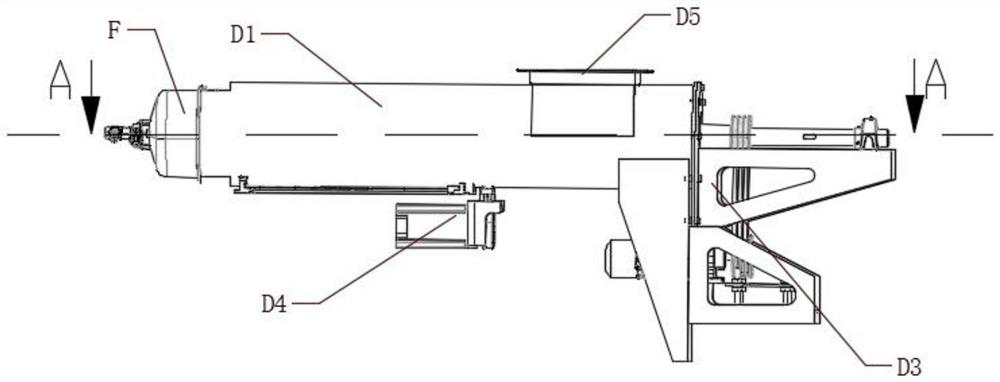

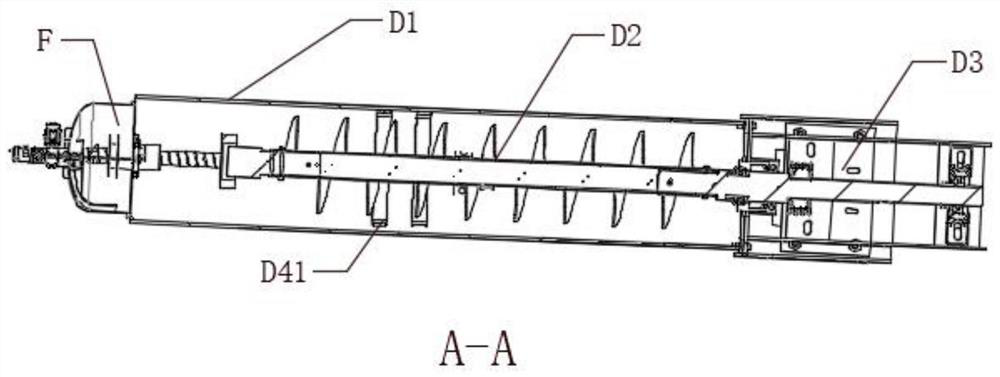

[0048] Such as Figure 1-11 As shown, a jaw crusher for engineering of the present invention includes a jaw crusher body 1, an iron removal device A, a filter material mechanism B and an iron transmission device D, and the iron removal device A is placed in the jaw crusher body 1, and the bottom of the iron removal device A is connected to the upper end of the feed port 10 of the jaw crusher body 1, and the side of the iron removal device A is provided with an iron absorption unit A3, and the iron absorption unit A3 extends into the fixed jaw plate In the V-shaped cavity formed between the movable jaw plate, the filter mechanism B is set inside the iron-absorbing unit A3, the iron transmission device D is connected to the middle of the iron-absorbing unit A3, and the iron transmission device D is connected to the iron-absorbing unit Iron unit A3 is connected.

[0049] The present invention solves the problem of the moisture brought in by the stone during the construction of t...

Embodiment 2

[0061] This embodiment is a further improvement of the previous embodiment, such as Figure 1-11 As shown, a jaw crusher for engineering of the present invention includes a jaw crusher body 1, an iron removal device A, a filter material mechanism B and an iron transmission device D, and the iron removal device A is placed in the jaw crusher body 1, and the bottom of the iron removal device A is connected to the upper end of the feed port 10 of the jaw crusher body 1, and the side of the iron removal device A is provided with an iron absorption unit A3, and the iron absorption unit A3 extends into the fixed jaw plate In the V-shaped cavity formed between the movable jaw plate, the filter mechanism B is set inside the iron-absorbing unit A3, the iron transmission device D is connected to the middle of the iron-absorbing unit A3, and the iron transmission device D is connected to the iron-absorbing unit Iron unit A3 is connected.

[0062] The present invention solves the problem...

Embodiment 3

[0077] This embodiment is a further improvement of the previous embodiment, such as Figure 1-11 As shown, a jaw crusher for engineering of the present invention includes a jaw crusher body 1, an iron removal device A, a filter material mechanism B and an iron transmission device D, and the iron removal device A is placed in the jaw crusher body 1, and the bottom of the iron removal device A is connected to the upper end of the feed port 10 of the jaw crusher body 1, and the side of the iron removal device A is provided with an iron absorption unit A3, and the iron absorption unit A3 extends into the fixed jaw plate In the V-shaped cavity formed between the movable jaw plate, the filter mechanism B is set inside the iron-absorbing unit A3, the iron transmission device D is connected to the middle of the iron-absorbing unit A3, and the iron transmission device D is connected to the iron-absorbing unit Iron unit A3 is connected.

[0078] The present invention solves the problem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com