A crop organic solid waste pretreatment system

An organic solid, pretreatment technology, applied in the field of resources and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

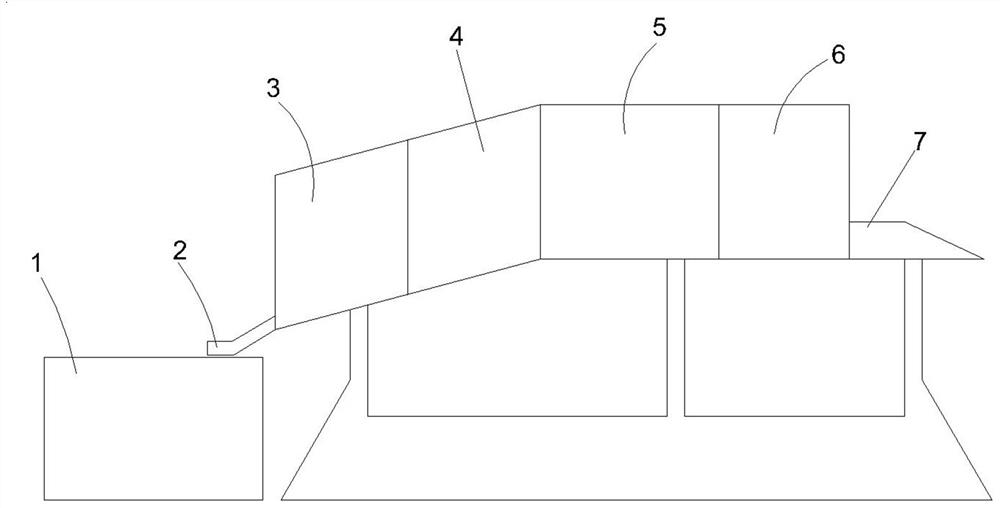

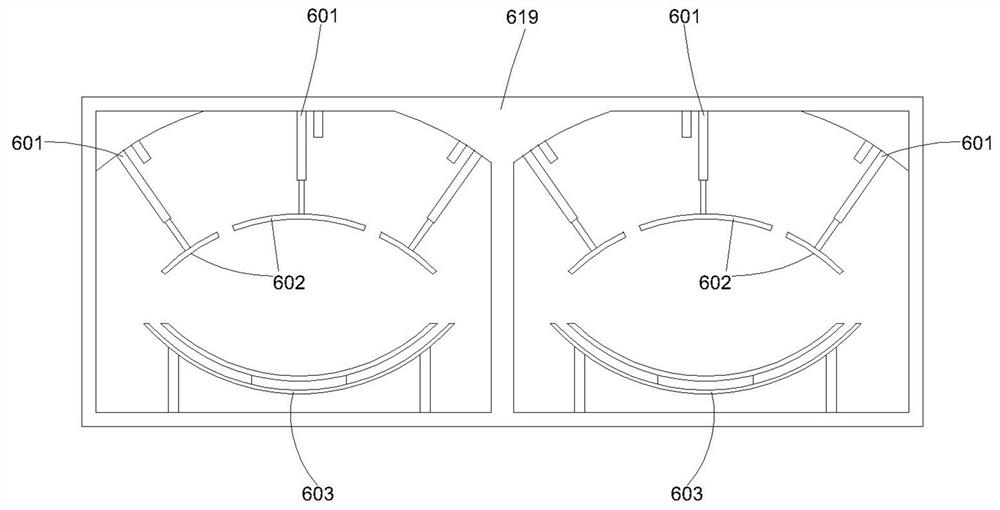

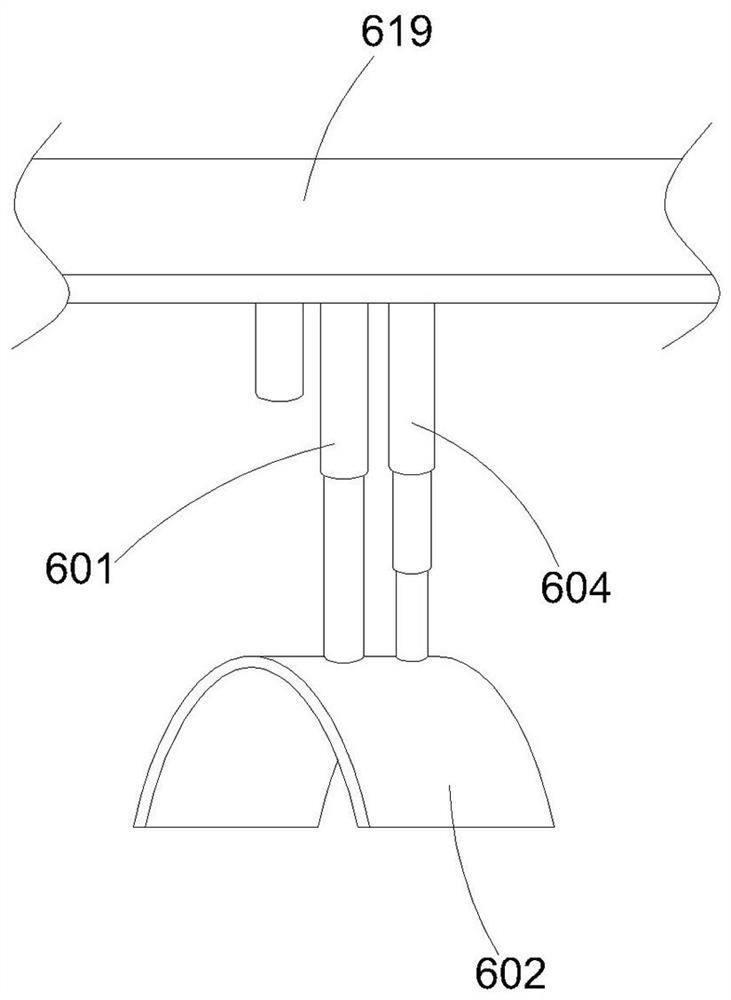

[0042] A crop organic solid waste pretreatment system, its structure is as follows Figure 1-Figure 13 shown, where Figure 8 Unrepresented regulated motors, Figure 13 The fine crushing knife net is not shown in the interior; it includes a cutting system, a crushing system, a compression system and a control system that cooperates with the cutting system, a crushing system, and the compression system; the cutting system includes an extrusion device 6 and a cutting device that cooperates with the extrusion device 6 Device 5; the crushing system includes a preliminary crushing device 4 and a fine crushing device 3; the compression system includes a fine material pressing device 1 matched with the fine crushing device 3. The extruding device 6 includes a pair of straw feeding passages 7, any straw feeding passage 7 is connected with a straw extruding chamber 619, and a straw extruding mechanism is arranged in the straw extruding chamber 619; the cutting device 5 includes a stra...

Embodiment 2

[0049] A crop organic solid waste pretreatment system differs from Embodiment 1 in that fine grinding protrusions are evenly arranged on the inner wall of the fine grinding chamber 314 .

Embodiment 3

[0051] A crop organic solid waste pretreatment system, which is different from Embodiment 1 in that: a straw coarse material inspection tube is provided on the round table-shaped crushing cylinder 405, and the other end of the straw coarse material inspection tube is connected to the straw crushing tube 402 , The straw coarse material inspection pipe is provided with an inspection port, and the inspection port is provided with an inspection valve; the straw coarse material inspection pipe is provided with a return valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com