Soft package non-modular power battery system

A power battery and battery management system technology, which is applied in the field of soft-pack non-modular power battery systems, can solve the problems of shortened heat transfer path, insufficient compact design, weight reduction and cost, etc., to achieve shorter heat transfer path and lower weight. Effects of lightening and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

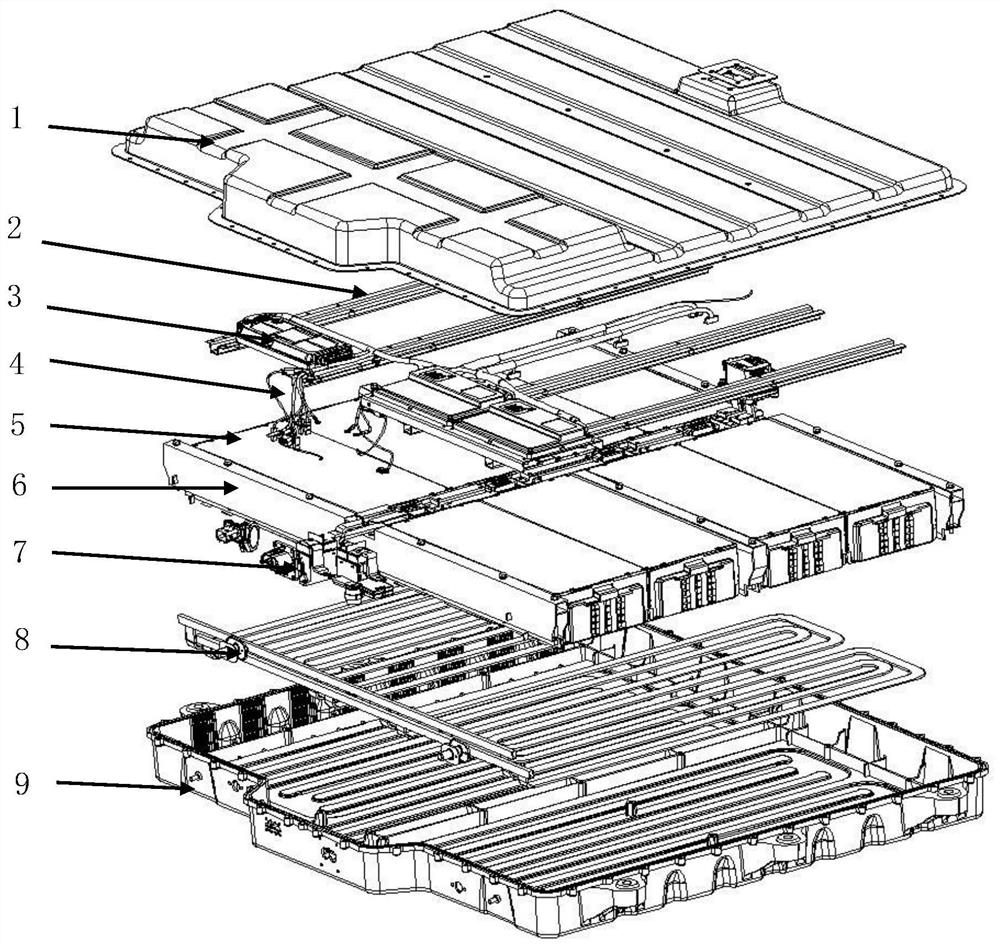

[0037] Embodiment: A soft pack non-modular power battery system of this embodiment, such as figure 1 As shown, the upper cover 1 and the lower box body assembly 9 including the fixed connection are fixedly connected to form a cavity. Between the upper cover 1 and the lower box assembly 9 , a pressure rod assembly 2 , a low-voltage wire harness 4 and a beam assembly 6 are arranged in sequence from top to bottom. The battery management system and low-voltage wiring harness are installed on the strut assembly, the soft-packed cell assembly and the high-voltage electrical assembly are installed on the beam assembly, and the liquid cooling system is installed on the lower box assembly. The battery management system 3 is arranged on the pressing rod 2.1, and isolation is provided between the battery management system 3, the soft-packed cell assembly 5 and the high-voltage electric assembly 7. The specific form of the battery management system is not limited. By the overhead arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com