Visual inspection method for defects of transparent packaging IC

A visual detection and defect technology, applied in the detection field, can solve the problems of high work intensity, low detection efficiency, and poor stability of detection results, etc., and achieve the effects of improving production efficiency and production quality, high detection accuracy, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] see Figure 1-Figure 2 , the visual detection method of the transparent encapsulation IC defect of the present invention, comprises the following steps;

[0030] (1) Place the product to be tested on the testing equipment, and select different visual devices according to the different sides of the product to collect the image information of each side of the product, and upload the collected image information to the processor ;

[0031] (2) After the processor receives the image information, it compares the image information with the standard image of OK products to find out the defective products, and selects the corresponding algorithm for the defects existing in each surface of the product. The process is as follows:

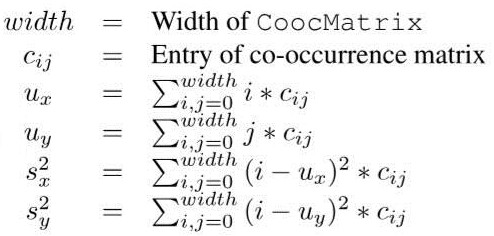

[0032] Firstly, according to the differences in the background on the texture of the image information, the gray level co-occurrence matrix is used to calculate the following four different texture representation features in the image information: ...

Embodiment 2

[0059] The present embodiment describes the visual detection method of the transparent package IC defect of the present invention with a specific case:

[0060] Taking frontal scratches as an example, after the visual device in Example 1 detects that there is a defect on the front of the product, the algorithm can detect the defect in a specific area on the front of the product, but it is not yet sure what kind of defect it is, because There are still defects such as dirt and bubbles on the front. At this time, it can be judged according to the shape of the defect and the change of gray value. For example, air bubbles and scratches will cause the local gray value to increase, and dirt will cause the local gray value to decrease. , and the bubbles are usually round, the scratches are linear, and the dirt has no fixed shape. At this time, if the algorithm judges that the defect causes the local gray value to increase, and the defect is linear, it can be considered that the defec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com