Automatic color-changing intelligent window and application thereof

A smart window and automatic technology, applied in windows/doors, optics, parallel glass structures, etc., can solve problems such as low transmittance contrast, poor device stability, and influence of transmittance, and achieve high transmittance difference, The effect of ultra-high stability and good photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

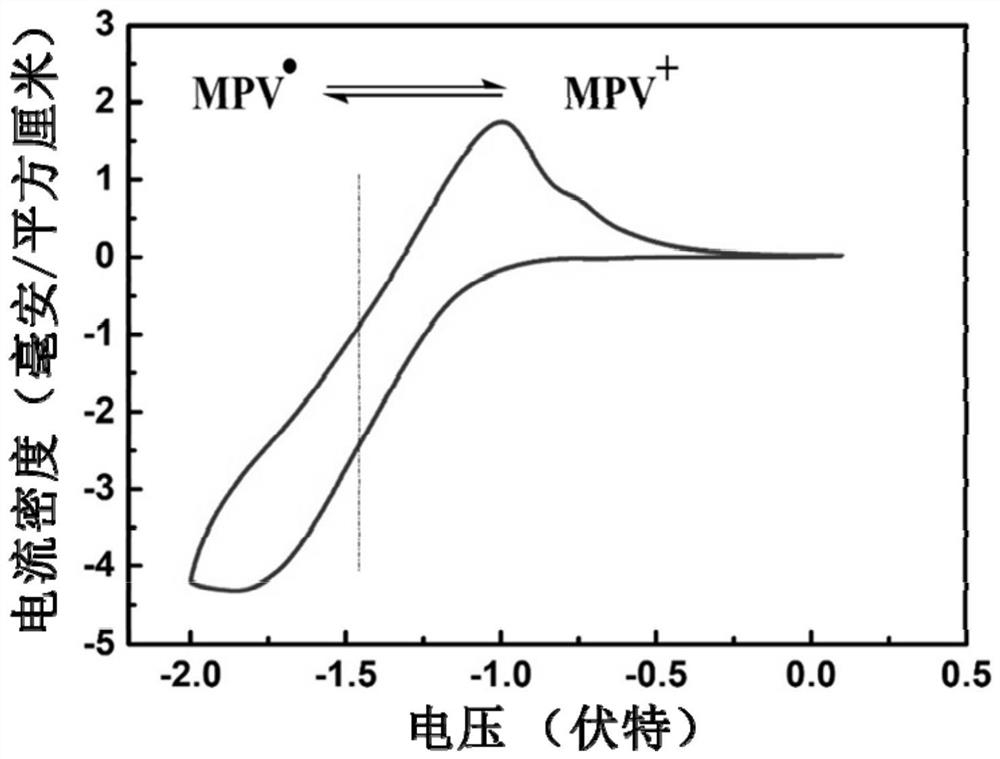

[0070] This preparation example provides an electrochromic material MPV, the structure is as follows:

[0071]

[0072] The preparation method is:

[0073]

[0074] Dissolve 4,4'-bipyridine (0.3g, 1.9mmol) and 5-chloro-1-pentyne (0.176g, 1.7mmol) in 2mL N,N-dimethylformamide, heat to 90°C, The reaction was stirred for 14 hours, and after cooling down to room temperature, the solvent was spin-dried on a rotary evaporator, and the obtained crude product was purified through a silica gel column to obtain the target product MPV as a gray solid, a total of 0.20 g, with a yield of 40%.

[0075] 1 H-NMR (400MHz, D 2 O): δ8.94(d, J=6.8Hz, 2H), 8.66(s, 2H), 8.33(s, 2H), 7.82(s, 2H), 4.74(t, J=6.8Hz, 2H), 2.40-1.98(m,5H).

preparation example 2

[0077] This preparation example provides an electrochromic material DPV, the structure is as follows:

[0078]

[0079] The preparation method is:

[0080]

[0081] Dissolve 4,4'-bipyridine (0.3g, 1.9mmol) and 5-chloro-1-pentyne (0.49g, 4.8mmol) in 2mL N,N-dimethylformamide, heat to 110°C, The reaction was stirred for 36 hours. After cooling down to room temperature, the crude product was precipitated and washed three times with N,N-dimethylformamide to obtain the target product DPV as a gray solid, 0.45 g in total, with a yield of 66%.

[0082] 1 H-NMR (400MHz, D 2 O): δ9.09(d, J=6.7Hz, 2H), 8.48(d, J=6.3Hz, 4H), 4.80(t, J=6.8Hz, 4H), 2.39-2.05(m, 10H).

Embodiment 1

[0084] The preparation method of the gel electrochromic device in this embodiment comprises the following steps:

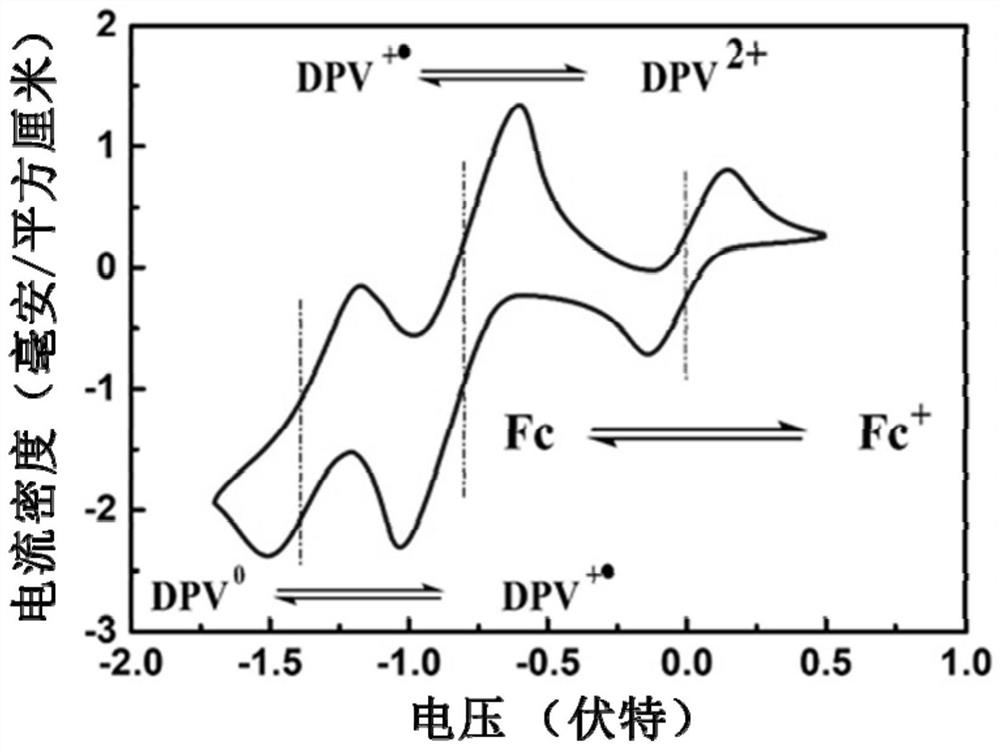

[0085] (1) In the glove box, the electrochromic material DPV (0.1mmol), ferrocene (0.8mmol, 23mg), propylene carbonate (150mg), lithium trifluoromethylsulfonimide provided by Synthesis Example 1 Salt (160 mg) and polypropylene butyral (300 mg, number average molecular weight 55000 g / mol) were dissolved in dry methanol (1.5 mL), stirred for 2 hours to obtain a uniform gel;

[0086] (2) Pour the gel into the liquid crystal cell. The liquid crystal cell is sandwiched by two pieces of conductive glass with a piece of paraffin film, and the two pieces of ITO face each other; Determined by the shape of the paraffin film, the effective area of discoloration is a circle with a radius of 0.8 cm and an area of 2 cm 2 .

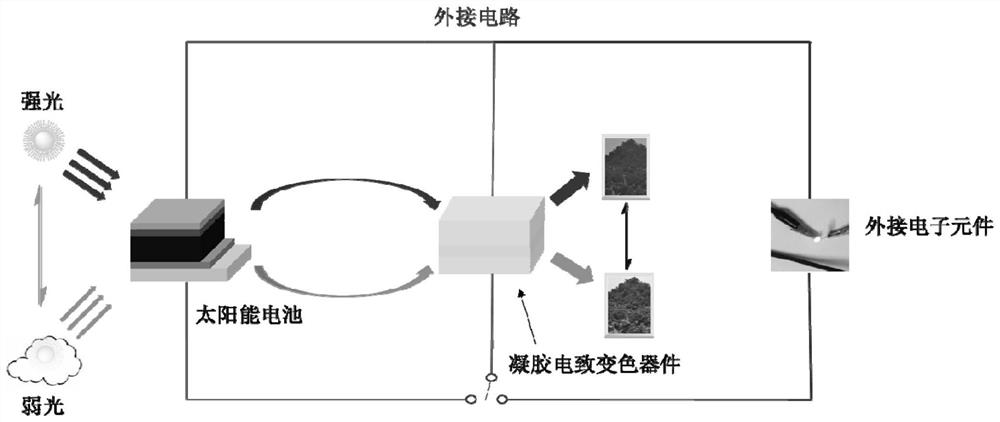

[0087] A gel electrochromic device is connected in series with a perovskite solar cell to form an automatic color-changing smart window.

[0088] Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photoelectricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com