Preparation method of fluorescent-agent-free matt art paper

A non-fluorescent, coated paper technology, applied in the field of papermaking, can solve the problems of high sizing cost, complicated sizing procedures, etc., and achieve the effect of high selling price, improving profit space and competitiveness, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

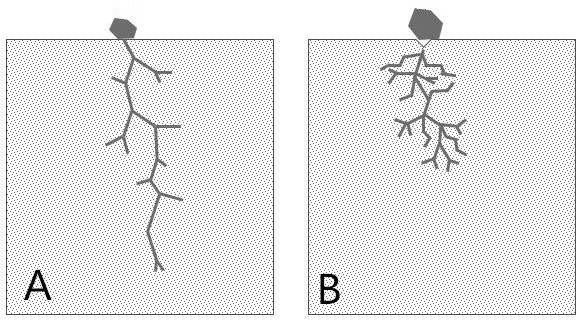

Image

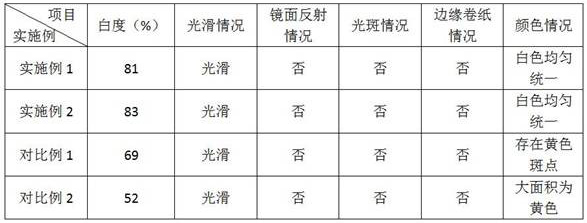

Examples

Embodiment 1

[0026] Glue adjustment: including 10 parts of polyethylene resin, 0.2 parts of dispersant, 0.3 parts of defoamer, 2 parts of binder, 8 parts of nano-titanium dioxide, 0.3 parts of thickener, and 15 parts of water;

[0027] Papermaking: the paper base for papermaking after preparing base paper pulp, the color of the paper base is light yellow;

[0028] Sizing: Run the paper on the paper surface sizing machine, sizing, double-sided sizing; after sizing per square meter, the weight of the paper increases by about 20g;

[0029] Quick freezing: Send the double-sided glued paper into the freezer, set the temperature of the freezer to 0°C, turn on the fan in the freezer to cool down quickly, after quick freezing, the paper becomes hard and dry, and there is no curl at the edge of the paper paper phenomenon;

[0030] Warming up: place the frozen paper at room temperature and let it warm up to room temperature;

[0031] Calendering: The surface is smooth and calendered with a super c...

Embodiment 2

[0034] Glue adjustment: including 10 parts of polyethylene resin, 0.3 parts of dispersant, 0.2 parts of defoamer, 1.5 parts of binder, 8 parts of nano-calcium carbonate, 0.4 parts of thickener, and 18 parts of water;

[0035] Papermaking: the paper base for papermaking after preparing base paper pulp, the color of the paper base is light yellow;

[0036] Sizing: Run the paper on the paper surface sizing machine, sizing, and double-sided sizing; the weight of the paper after sizing per square meter is about 21g;

[0037] Quick freezing: Send the double-sided glued paper into the freezer, set the temperature of the freezer to 0°C, turn on the fan in the freezer to cool down quickly, after quick freezing, the paper becomes hard and dry, and there is no curl at the edge of the paper paper phenomenon;

[0038] Warming up: place the frozen paper at room temperature and let it warm up to room temperature;

[0039] Calendering: The surface is smooth and calendered with a super calen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com