Polymer drag reducer for oil and gas exploitation and preparation process thereof

A preparation process and polymer technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems affecting the drag reduction rate of drag reducers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

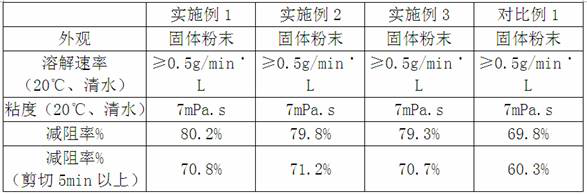

Examples

Embodiment 1

[0041] A polymer drag reducer for oil and gas development, consisting of drag reducing components, film-forming components and microcrystalline wax;

[0042] The polymer drag reducer used for oil and gas development is prepared through the following steps:

[0043] The first step is to prepare the drag reducing component;

[0044] The second step, preparing the film-forming component;

[0045] The third step is to weigh the drag-reducing component and the film-forming component according to the mass ratio of 3:2, set the temperature at 100°C, heat the film-forming component and the drag-reducing component to melt, stir and mix for 50min, and then set the temperature at 60±2°C Dry to constant weight to obtain the first component, then heat the microcrystalline wax at 95±2°C until it is completely dissolved, immerse the first component in the dissolved microcrystalline wax for 10±2s, take it out, and then quickly add it to deionized water Rapidly solidify and dry to obtain a p...

Embodiment 2

[0059] A polymer drag reducer for oil and gas development, consisting of drag reducing components, film-forming components and microcrystalline wax;

[0060] The polymer drag reducer used for oil and gas development is prepared through the following steps:

[0061] The first step is to prepare the drag reducing component;

[0062] The second step, preparing the film-forming component;

[0063] The third step is to weigh the drag-reducing component and the film-forming component according to the mass ratio of 3:2, set the temperature at 120°C, heat the film-forming component and the drag-reducing component to melt, stir and mix for 55min, and then set the temperature at 60±2°C Dry to constant weight to obtain the first component, then heat the microcrystalline wax at 95±2°C until it is completely dissolved, immerse the first component in the dissolved microcrystalline wax for 10±2s, take it out, and then quickly add it to deionized water Rapidly solidify and dry to obtain a p...

Embodiment 3

[0077] A polymer drag reducer for oil and gas development, consisting of drag reducing components, film-forming components and microcrystalline wax;

[0078] The polymer drag reducer used for oil and gas development is prepared through the following steps:

[0079] The first step is to prepare the drag reducing component;

[0080] The second step, preparing the film-forming component;

[0081] The third step is to weigh the drag-reducing component and the film-forming component according to the mass ratio of 4:2, set the temperature at 140°C, heat the film-forming component and the drag-reducing component to melt, stir and mix for 60min, and then heat the mixture at 60±2°C Dry to constant weight to obtain the first component, then heat the microcrystalline wax at 95±2°C until it is completely dissolved, immerse the first component in the dissolved microcrystalline wax for 10±2s, take it out, and then quickly add it to deionized water Quickly solidify and dry to obtain a poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com