Low-temperature carbon dioxide methanation catalyst and preparation method thereof

A methanation catalyst and carbon dioxide technology, applied in the field of natural gas, can solve problems such as poor stability, poor anti-coking performance, and low low-temperature activity, and achieve the effects of short preparation process, easy repeatability, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of low-temperature carbon dioxide methanation catalyst of the present invention, the detailed steps of this preparation method are as follows:

[0048] a. Add 7.50g of Al(NO 3 ) 3 9H 2 O and 0.56gNi(NO 3 ) 2 ·6H 2 O (both chemically pure) was dissolved in 100mL deionized water, and stirred for 1h under a magnetic stirrer to obtain a mixed solution;

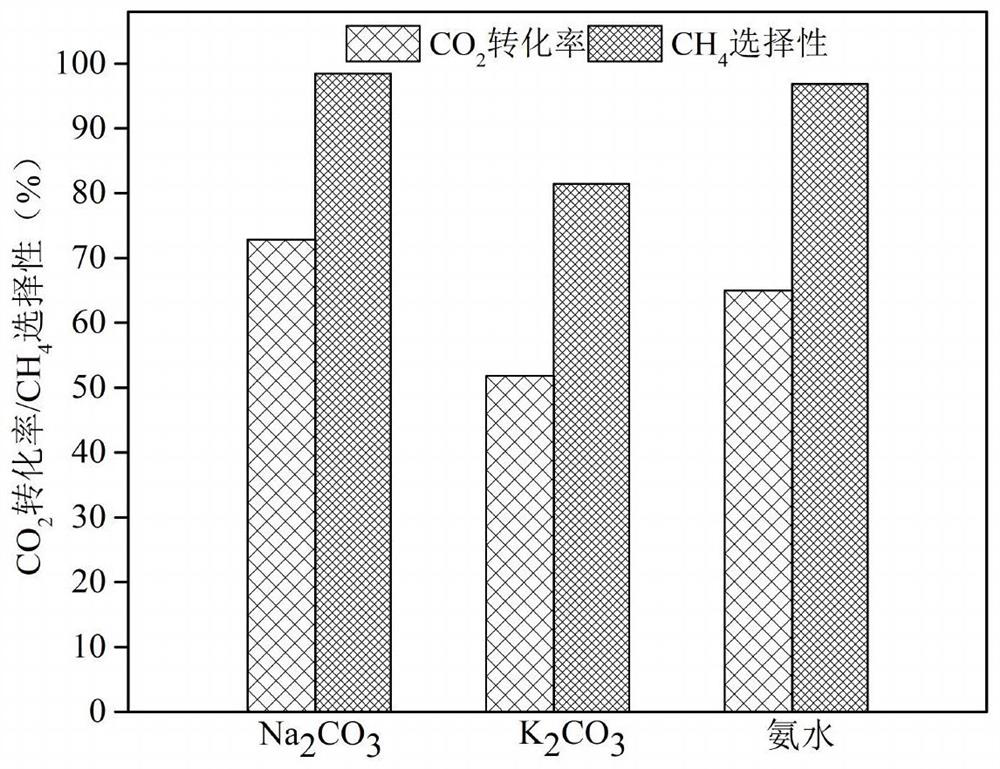

[0049] b. Under the condition of 65℃ and constant stirring, add 1.0mol / L Na 2 CO 3 Solution is added dropwise in step a gained mixed solution (Na 2 CO 3 The solution is obtained by dissolving anhydrous sodium carbonate in deionized water), and the dropwise addition is completed when the pH value of the mixed solution is 9; then continue stirring at 65° C. for 2 hours to obtain a solid-liquid mixture;

[0050] c. Aging the solid-liquid mixture obtained in step b for 24 hours, washing with distilled water after aging until the pH value of the solution is 7, and obtaining a solid sample;

[005...

Embodiment 2

[0054] The preparation method of low-temperature carbon dioxide methanation catalyst of the present invention, the detailed steps of this preparation method are as follows:

[0055] a. Add 6.26g Al(NO 3 ) 3 9H 2 O, 1.42g Zr(NO 3 ) 4 ·5H 2 O and 0.69g Ni(NO 3 ) 2 ·6H 2 O (both chemically pure) was dissolved in 100mL deionized water, and stirred for 1h under a magnetic stirrer to obtain a mixed solution;

[0056] b. Under the condition of 60°C and constant stirring, use a peristaltic pump to add 0.8 mol / L Na to the precipitant 2 CO 3 Solution is added dropwise in step a gained mixed solution (Na 2 CO 3 The solution is obtained by dissolving anhydrous sodium carbonate in deionized water), and the dropwise addition is completed when the pH value of the mixed solution is 10; then the stirring is continued at 60° C. for 2 hours to obtain a solid-liquid mixture;

[0057] c. Aging the solid-liquid mixture obtained in step b for 24 hours, washing with distilled water after ...

Embodiment 3

[0061] The preparation method of low-temperature carbon dioxide methanation catalyst of the present invention, the detailed steps of this preparation method are as follows:

[0062] a. Add 5.36g Al(NO 3 ) 3 9H 2 O, 2.44g Zr(NO 3 ) 4 ·5H 2 O and 0.78g Ni(NO 3 ) 2 ·6H 2 O (both chemically pure) was dissolved in 100mL deionized water, and stirred for 1h under a magnetic stirrer to obtain a mixed solution;

[0063] b. Under the condition of 70°C and constant stirring, use a peristaltic pump to add 0.5 mol / L Na to the precipitant 2 CO 3 Solution is added dropwise in step a gained mixed solution (Na 2 CO 3 The solution is obtained by dissolving anhydrous sodium carbonate in deionized water), and the dropwise addition is completed when the pH value of the mixed solution is 10; then the stirring is continued at 70° C. for 2 hours to obtain a solid-liquid mixture;

[0064] c. Aging the solid-liquid mixture obtained in step b for 24 hours, washing with distilled water after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com