Proportioning device and preparation method of polycarboxylate superplasticizer

A technology of water reducing agent and polycarboxylic acid, which is applied in the proportioning device of polycarboxylic acid water reducing agent and its preparation field, which can solve the problems of unsafe, unenvironmental protection, cumbersome operation process, etc., and reduce the fluctuation of the proportioning quality , stable uniformity, and the effect of improving the ratio efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

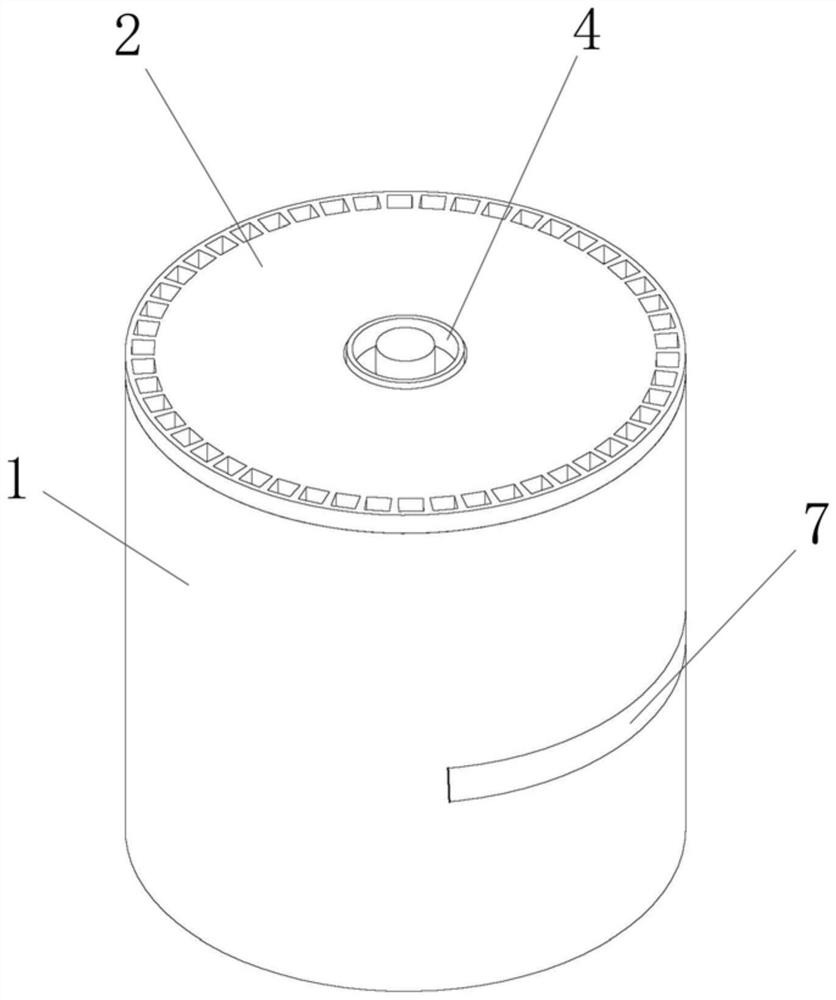

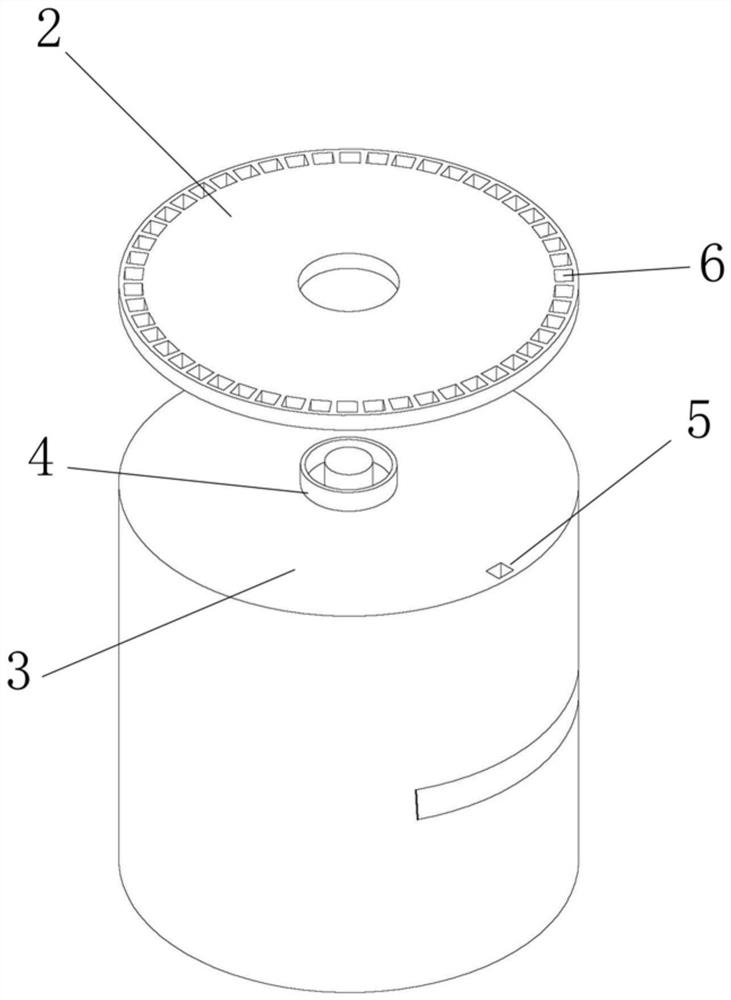

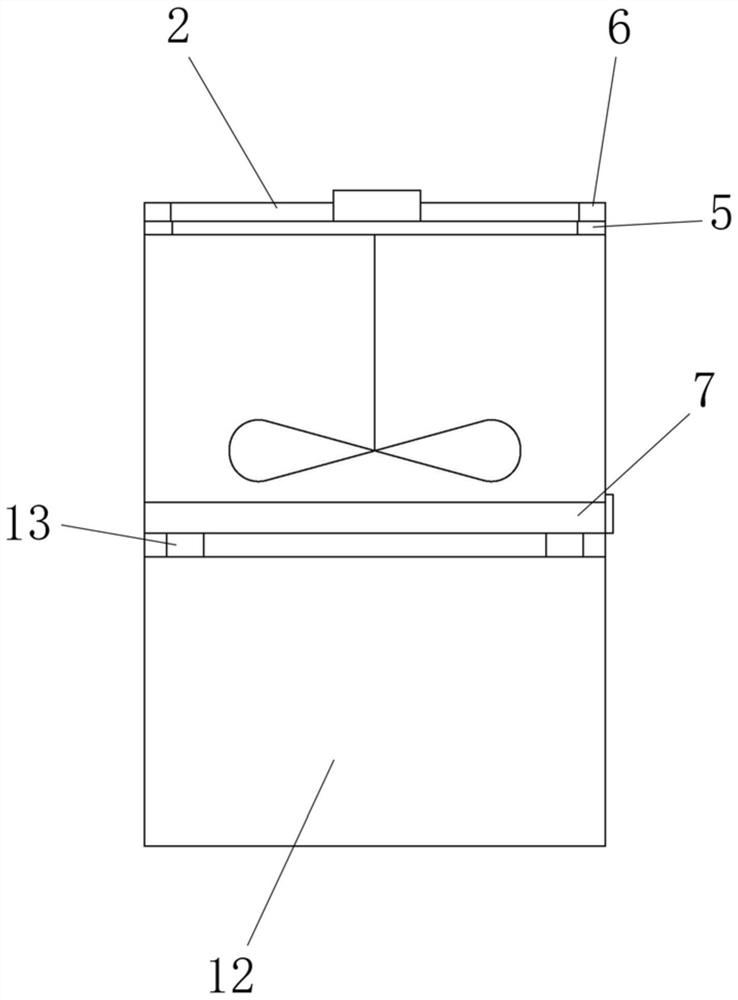

[0026] Example 1, such as Figure 1 to Figure 9 As shown, a proportioning device for polycarboxylate water reducer, which includes a mixing tank 1, a batching plate 2 and a finished product part, the mixing tank 1 includes a barrel cover 3 and a barrel body, and there is a ring plate on the barrel cover 3 4. The material leakage port 5 and the stirring motor, the ring plate 4 is a cylindrical ring surface protrusion located in the middle of the barrel cover 3, the material leakage port 5 is a through hole which is close to the edge of the barrel cover 3 and vertically runs through the barrel cover 3, and the stirring The motor is placed in the ring plate 4, the output shaft of the stirring motor extends down into the barrel body and is connected to the stirring net at the lower end, the batching plate 2 is ringed around the ring plate 4, and there are circularly distributed feeding grids 6 on the batching plate 2 , the material storage grid 6 is a rectangular grid that runs th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com