Preparation method and application of myrothamnus flabellifolia extract

A technology of extract and miro, applied in the field of preparation of miro extract, can solve problems such as low extraction rate of flavonoids, and achieve excellent effects, excellent anti-aging and anti-oxidation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

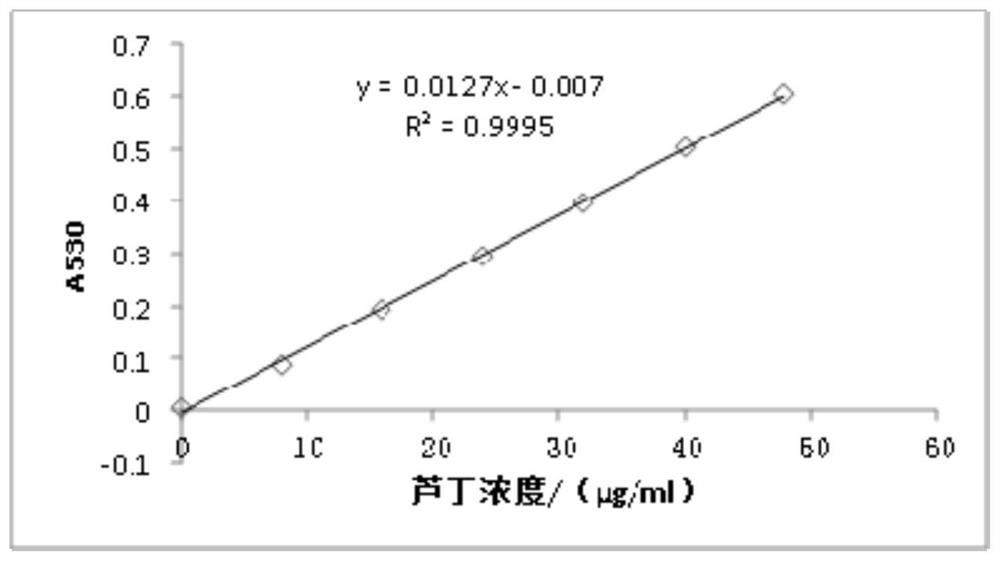

Method used

Image

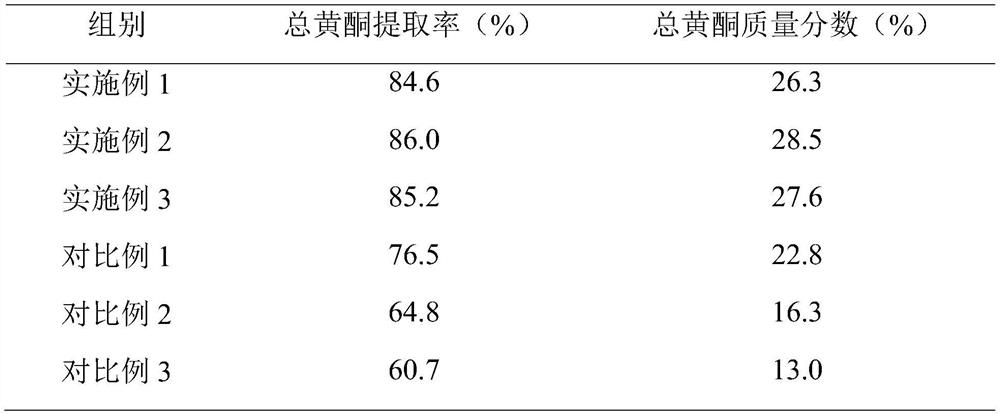

Examples

Embodiment 1

[0030] Embodiment 1, milo wood extract

[0031] Described preparation method is specifically:

[0032] A) the Milo wood is pulverized to obtain the first powder after passing through a 40 mesh sieve;

[0033] B) Take the first powder in step A), add petroleum ether in an amount 8 times the total amount of the above powder and soak overnight to obtain a degreasing mixture; filter the degreasing mixture, and dry the obtained filter residue to obtain a second powder;

[0034] C) Mix the second powder of step B) with the extraction solvent in a weight ratio of 1:45, extract at 3°C for 1 hour, extract with 380W ultrasonic at 45°C for 1 hour, heat in a boiling water bath for 10 minutes to inactivate the enzyme, and extract the enzyme after inactivating The liquid was centrifuged at 4500rmp in a centrifuge for 30min, and the filter residue was removed to obtain a supernatant; the supernatant was preliminarily purified through a 400nm ceramic membrane to obtain a filtrate; the fi...

Embodiment 2

[0036] Embodiment 2, milo wood extract

[0037] Described preparation method is specifically:

[0038] A) the Milo wood is pulverized to obtain the first powder after passing through a 40 mesh sieve;

[0039] B) Take the first powder in step A), add petroleum ether in an amount 10 times the total amount of the above powder and soak overnight to obtain a degreasing mixture; filter the degreasing mixture, and dry the obtained filter residue to obtain a second powder;

[0040] C) Mix the second powder of step B) with the extraction solvent in a weight ratio of 1:60, extract at 3°C for 1.5h, and at 45°C with 380W ultrasonic extraction for 1.5h, heat in a boiling water bath for 15min to inactivate the enzyme. The extract was centrifuged at 4500rmp for 30min in a centrifuge, and the filter residue was removed to obtain a supernatant; the supernatant was preliminarily purified through a 400nm ceramic membrane to obtain a filtrate; the filtrate was concentrated under reduced pres...

Embodiment 3

[0042] Embodiment 3, milo wood extract

[0043] Described preparation method is specifically:

[0044] A) the Milo wood is pulverized to obtain the first powder after passing through a 40 mesh sieve;

[0045] B) Take the first powder in step A), add petroleum ether in an amount 10 times the total amount of the above powder and soak overnight to obtain a degreasing mixture; filter the degreasing mixture, and dry the obtained filter residue to obtain a second powder;

[0046]C) Mix the second powder of step B) with the extraction solvent in a weight ratio of 1:50, extract at 5°C for 1 hour, extract with 380W ultrasonic at 50°C for 1 hour, heat in a boiling water bath for 15 minutes to inactivate the enzyme, and extract The liquid was centrifuged at 4500rmp in a centrifuge for 30min, and the filter residue was removed to obtain a supernatant; the supernatant was preliminarily purified through a 400nm ceramic membrane to obtain a filtrate; the filtrate was concentrated under re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com