A tool trajectory generation method for micro-milling repair with variable step distance for damage points on the surface of optical crystals

A technology of surface damage and optical crystals, which is applied in the direction of cutting tools for milling machines, manufacturing tools, milling machine equipment, etc., can solve problems such as damage to optical components, and achieve the effect of improving the ability to resist laser damage and enhance the ability to resist strong laser damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

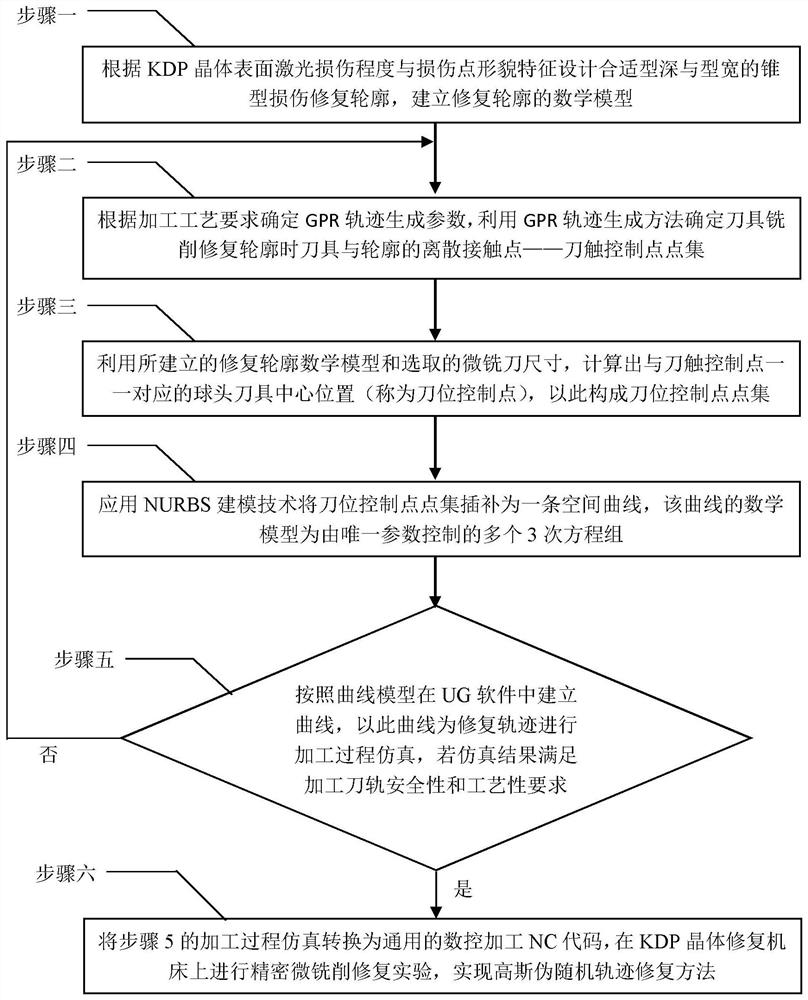

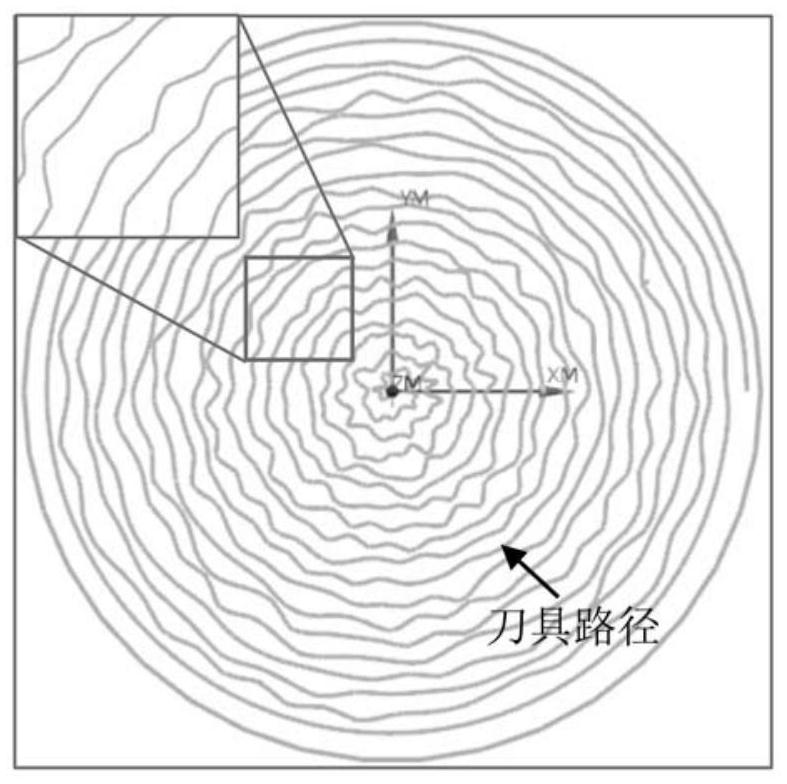

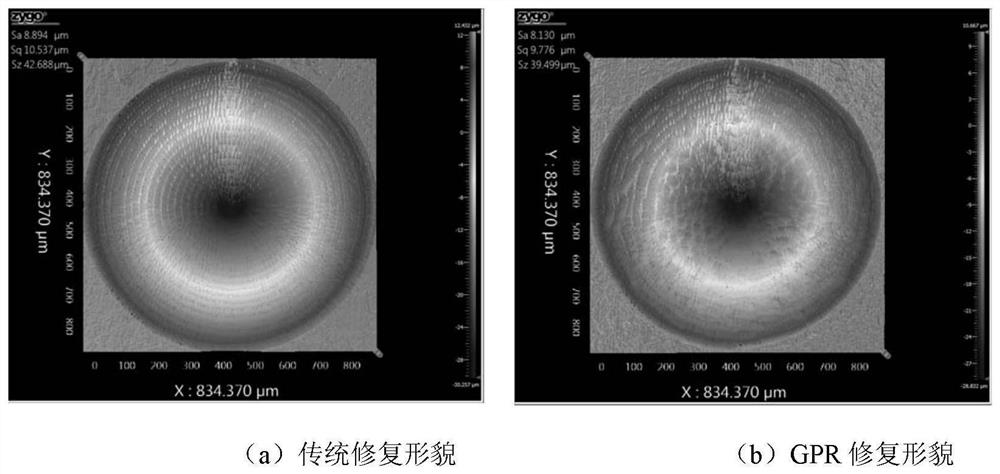

[0061] An example analysis of the generation of GPR micro-repair trajectory at the defect point on the surface of the KDP crystal element, using the above method according to figure 1 The process shown in the figure completes the experimental verification of the variable step-spacing repair trajectory generation method.

[0062] 1) According to the degree of laser damage on the surface of the KDP crystal and the shape characteristics of the damage point, a damage repair profile with a suitable depth and width is designed, and a mathematical model of the repair profile is established;

[0063] The laser damage experiment shows that the laser damage caused by ablation often occurs on the crystal surface, which is characterized by a large damage area and a shallow depth, and the tapered repair profile can better remove the damaged area. The optical simulation verification shows that the conical repair profile is a laser "friendly" repair profile, which can effectively improve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com