Liquid sealed vacuum glass for glass curtain wall

A technology of vacuum glass and glass curtain wall, which is applied to the sealing of vacuum gauges, walls, and engines, etc., which can solve the problems of potential safety hazards, high maintenance costs, and poor practicability, and achieve the elimination of potential safety hazards, high accuracy, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

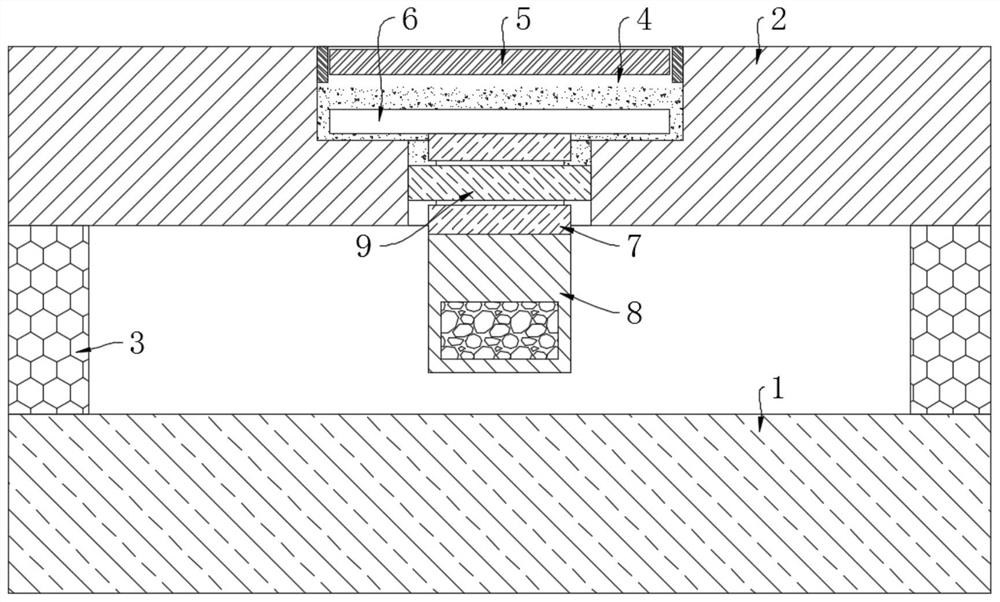

[0021] refer to figure 1 , a liquid-sealed vacuum glass for a glass curtain wall, comprising an outer layer plate 1 and an inner layer plate 2, an annular sealing strip 3 is fixedly arranged between the outer layer plate 1 and the inner layer plate 2, the outer layer plate 1, the inner layer plate 2 The sealed space formed by the layer plate 2 and the sealing strip 3 is a vacuum layer, and the side of the inner layer plate 2 far away from the vacuum layer is provided with a liquid storage tank 4, and the bottom groove wall of the liquid storage tank 4 is connected with the vacuum layer and has a through hole. The liquid tank 4 is slidingly connected with the limit block 6, the lower end of the limit block 6 is coaxial and vertically fixedly connected with the connecting rod 7, and the lower end of the connecting rod 7 extends through the through hole into the vacuum layer and is fixedly connected with the placement box 8, which is located at An annular groove is provided on th...

Embodiment 2

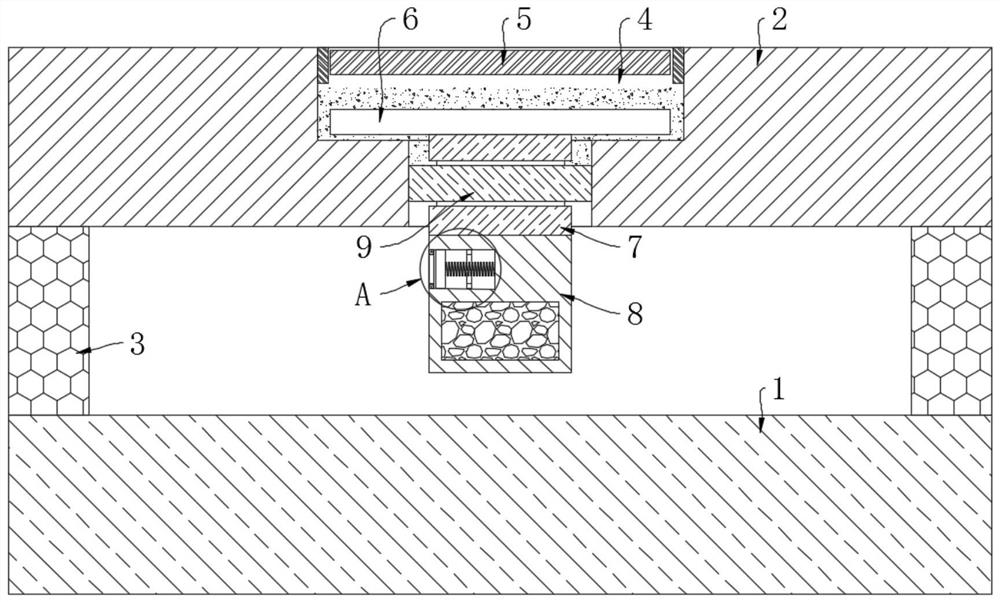

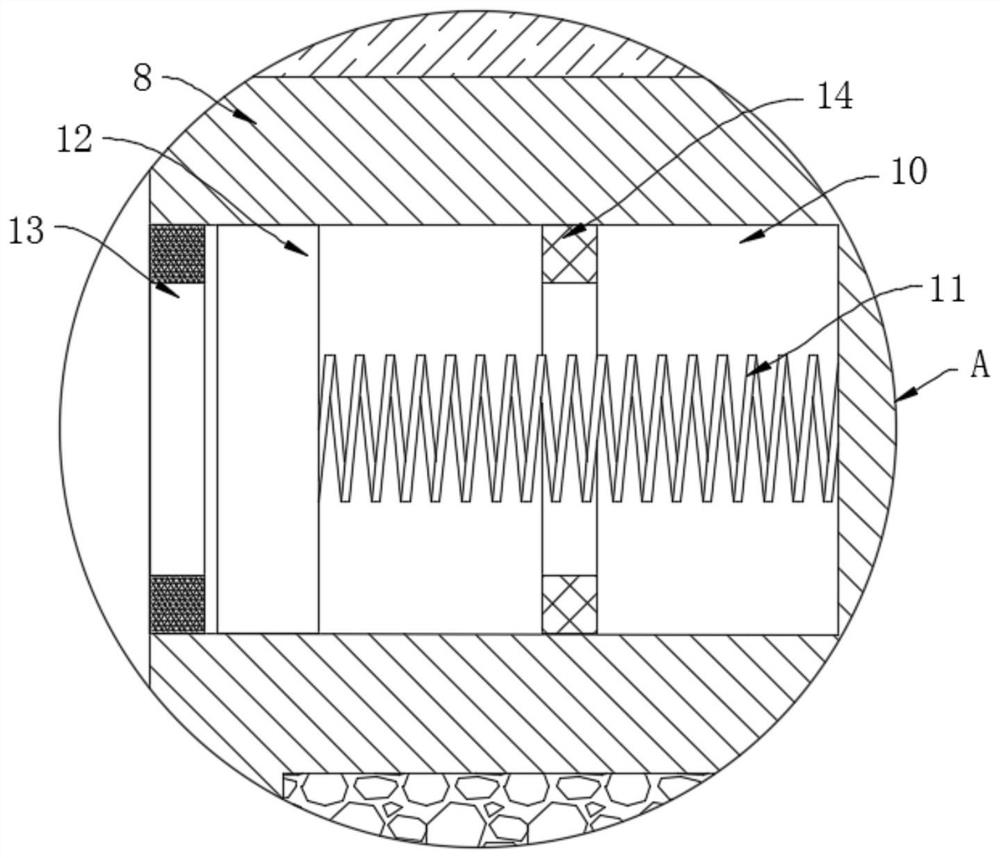

[0026] refer to Figure 2-3 The difference between this embodiment and Embodiment 1 is that: the side wall of the storage box 8 is provided with an installation groove 10, the notch of the installation groove 10 is fixedly provided with a limit ring 13, and the installation groove 10 is vertically fixedly connected with a ring-shaped pressure ring. Electric sheet 14, the groove wall of mounting groove 10 is elastically connected with piston block 12 by limit spring 11, and piston block 12 is connected with the groove wall of mounting groove 10 sealing sliding, and piston block 12 is positioned at piezoelectric sheet 14 and position-limiting Between the rings 13, the piezoelectric sheet 14 is electrically connected with external signal transmitting equipment through wires.

[0027] When the initial vacuum layer is in a vacuum environment, the piston block 12 is subjected to the negative pressure of the vacuum layer to stretch the limit spring 11 and resist the limit ring 13. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com