Alginate fiber cotton and preparation method thereof

A technology of seaweed fiber and seaweed cellulose, which is applied in textiles, papermaking, non-woven fabrics, adhesives, etc., can solve the problems of large differences in the network structure of fiber cotton and affect the use effect, and achieve good quality and promote blood circulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

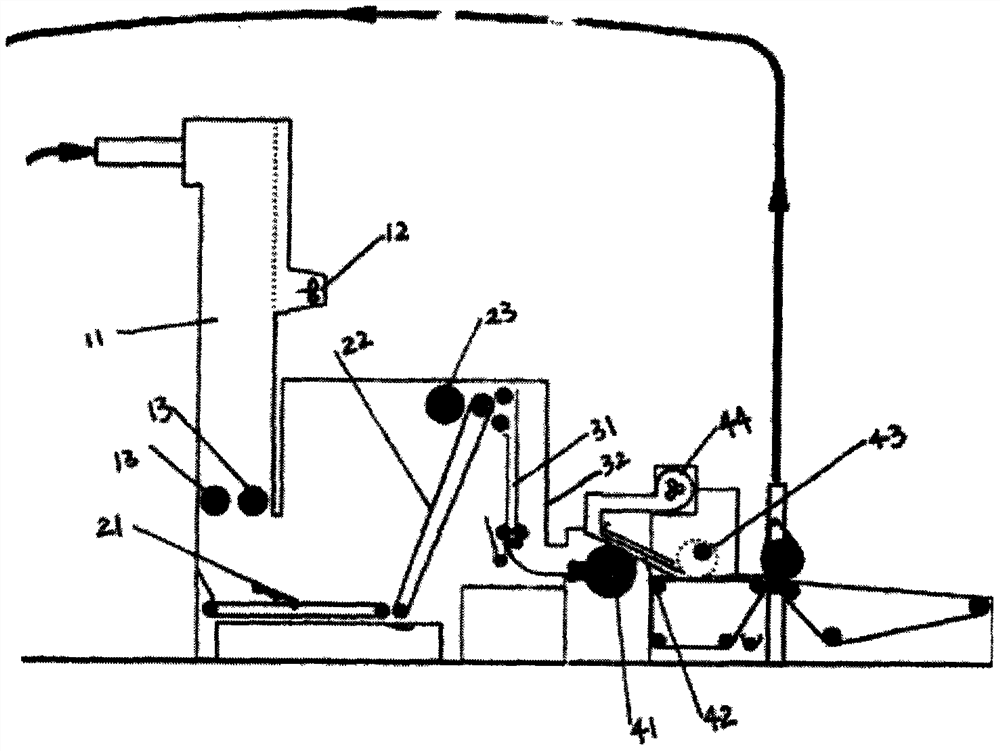

[0027] In order to achieve the best effect of a seaweed fiber cotton and its preparation method of the present invention, the air-laid fiber cotton developed by the applicant is used to prepare the production process and equipment. The equipment and process have applied for a patent (patent number 200820046243.9), and now Combined with the equipment and process, the present seaweed fiber cotton and its preparation method are described.

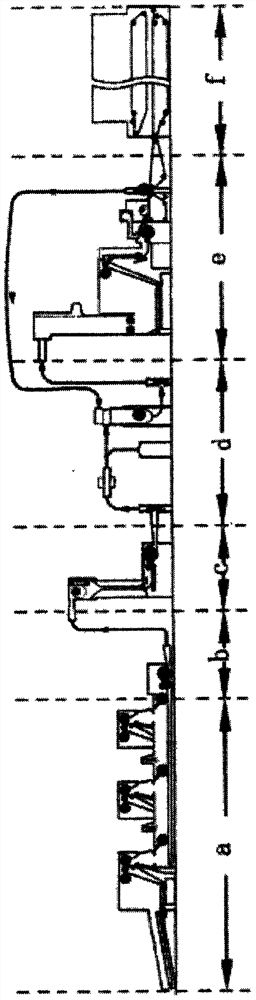

[0028] refer to figure 1 A schematic diagram of the production process and equipment structure for the preparation of seaweed fiber cotton according to the invention, the invention can be applied to a fully enclosed (only a few import and export materials) computer-controlled automatic production line.

[0029] A method for preparing seaweed fiber cotton, using low-melting fiber with a weight ratio of 5% to 85% and seaweed cellulose fiber 95% to 15% to prepare raw materials, the seaweed cellulose fiber is seaweed extract, and the prepared raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com