Intelligent manufacturing device for cleaning scratches on glass surface

A technology for intelligent manufacturing and cleaning of glass, which is applied to machine tools, manufacturing tools, and grinding/polishing safety devices suitable for grinding workpiece planes. It can solve problems affecting work efficiency, glass scratches, and slow grinding speed, etc., to achieve good stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

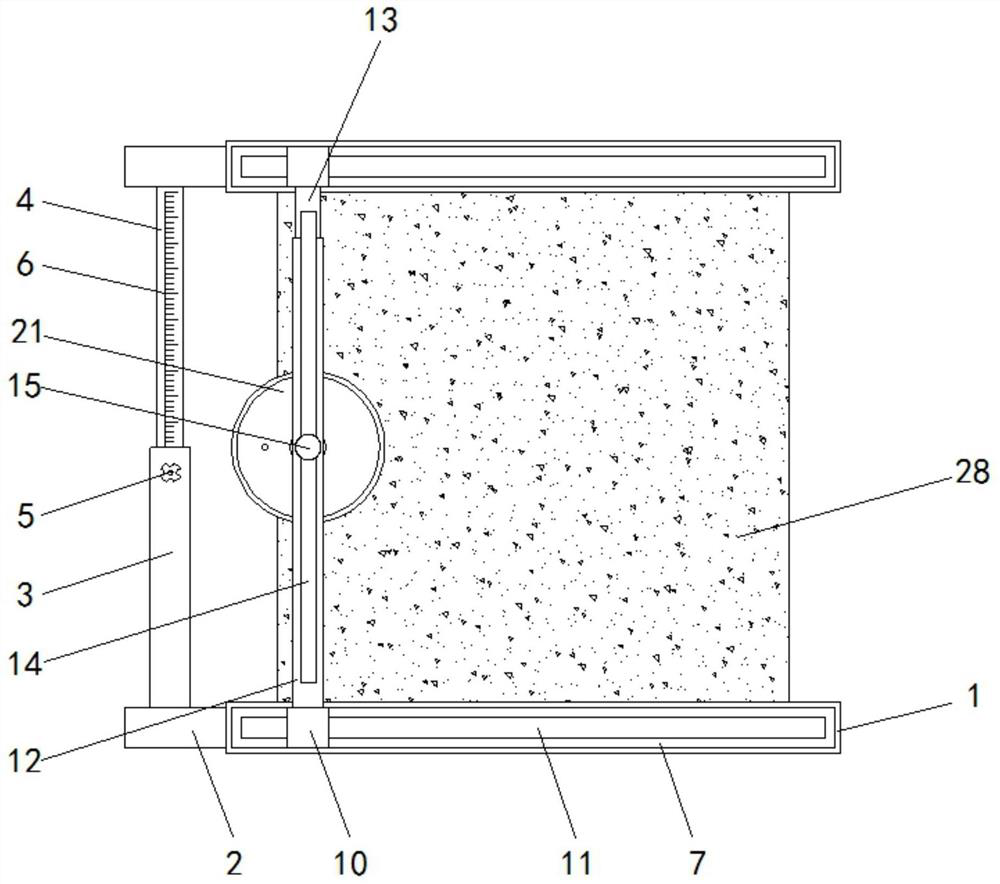

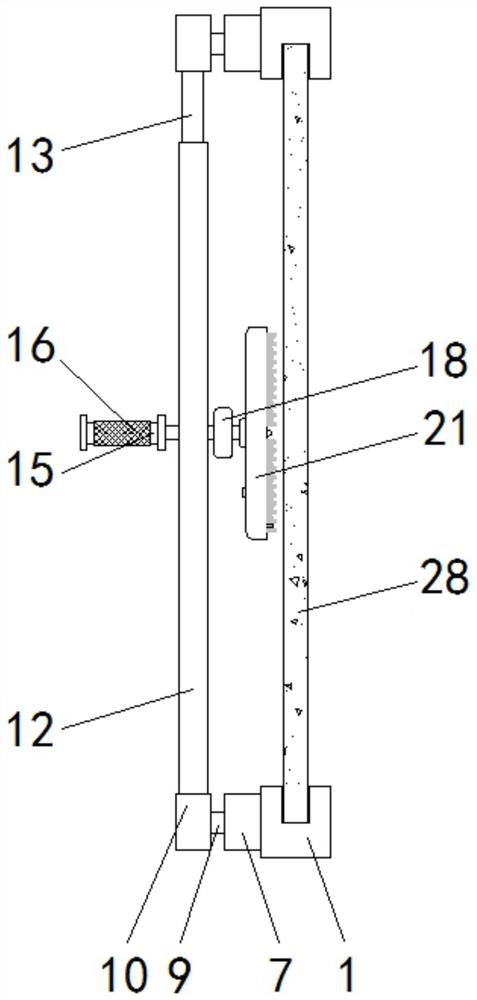

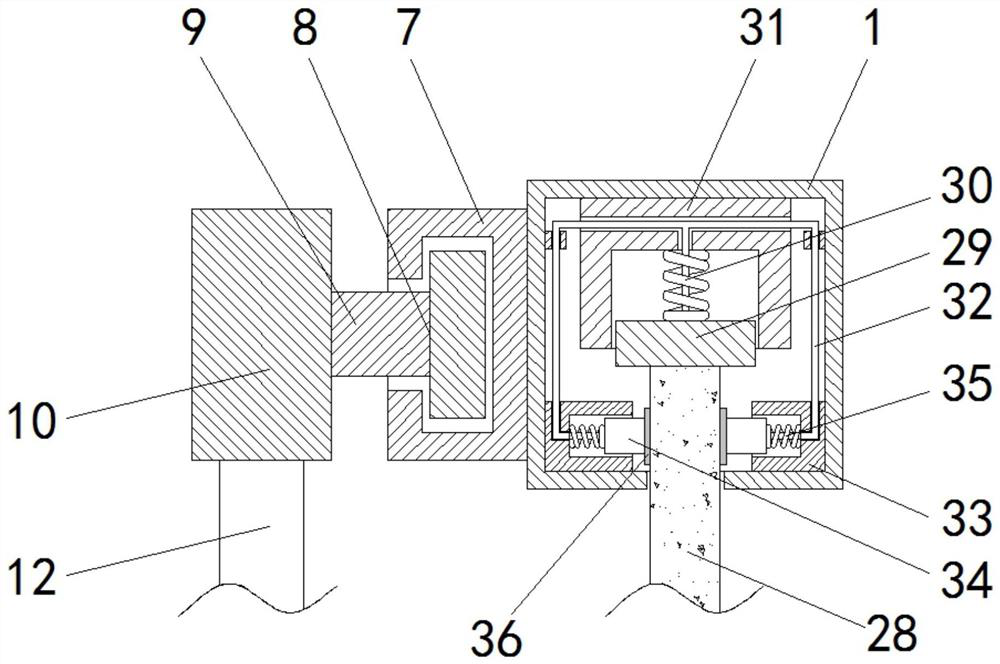

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] The invention provides an intelligent manufacturing device for cleaning scratches on the glass surface, which comprises a frame 1, a fixing part 2 is fixedly installed on the left side of the frame 1, and a first lifting rod 3 and a second lifting rod 3 are installed between the fixing parts 2. Shrinking rod 4, the front side of the first lifting and shrinking rod 3 is movably equipped with a locking member 5, the first rising and shrinking rod 3 and the second rising and shrinking rod 4 are fixedly connected by the locking member 5, and the first lifting and shrinking rod 5 is used to lock the first lifting rod 5. The retractable rod 3 is locked with the second retractable rod 4, so that the equipment achieves a good effect of stability. The front side of the second retractable rod 4 is fixedly provided with a scale mechanism 6, which is convenient for the user to operate by setting the scale mechanism 6. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com