Submerged arc welding method of low mo refractory steel

A submerged arc welding and refractory technology, applied in welding equipment, welding medium, welding equipment and other directions, can solve the problems such as the inability to stably meet the technical requirements of new refractory steel welded joints, the submerged arc welding process unable to meet the requirements, and the increase of Nb content. Achieve the effect of benefiting residents' safety, saving Mo metal resources, and reducing economic losses

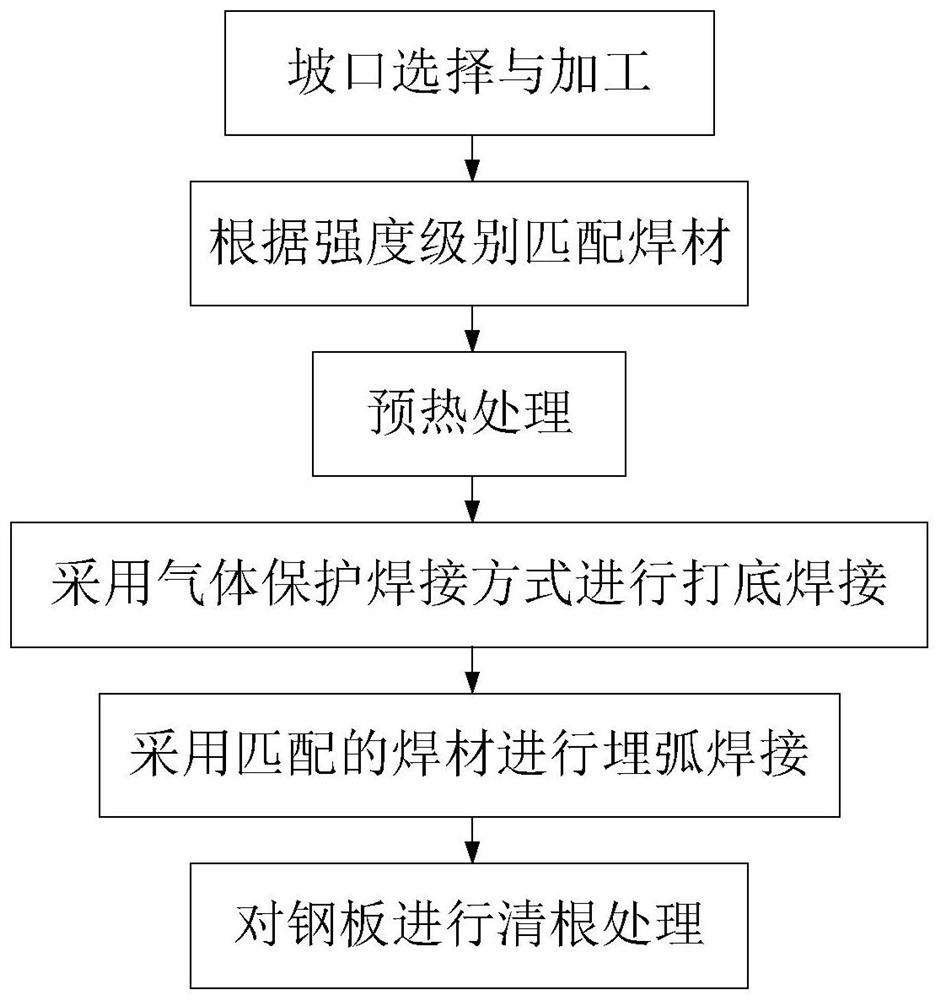

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

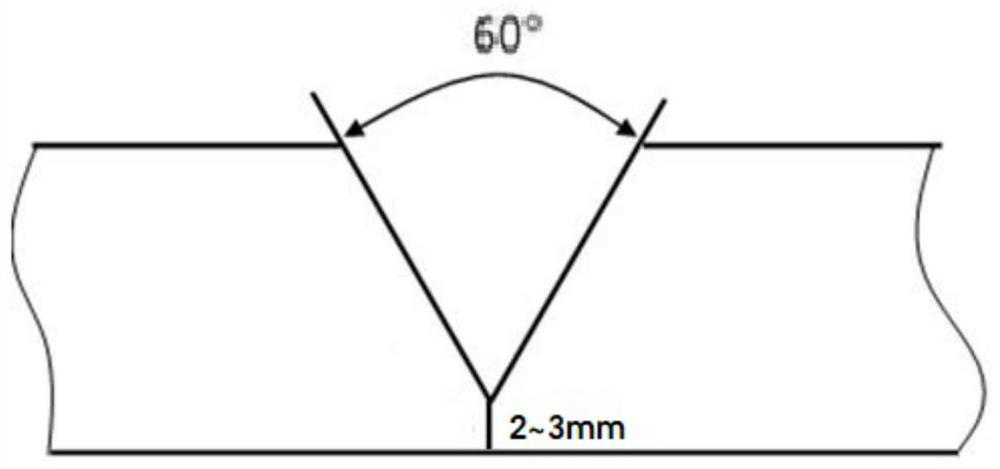

[0036] Example 1: Submerged arc welding is carried out on the new low-Mo refractory steel Q390FRE grade steel with a specification of 15mm, and the welding position is horizontal welding.

[0037] (1) using such as figure 2 As shown in the V-shaped welding groove, the groove angle is 30° on one side, 2mm-3mm blunt edge is left at the root, and 4-6° anti-deformation is reserved when the steel plate is assembled;

[0038] (2) For the Q390FRE steel plate, Harbin Well Welding submerged arc welding wire H390FRΦ4.0 and submerged arc flux SJ18 are mainly used, while in step (4) for bottom welding, Harbin Weil Welding gas shielded welding wire HS390FRΦ1.2 is used; The coordination of several welding materials fully meets the requirements of the present invention for welding deposited metal components;

[0039] (3) The steel plate is preheated at 40°C;

[0040](4) Carry out 2 rounds of bottom welding on the steel plate, using the gas shielded welding method. The first welding curre...

Embodiment 2

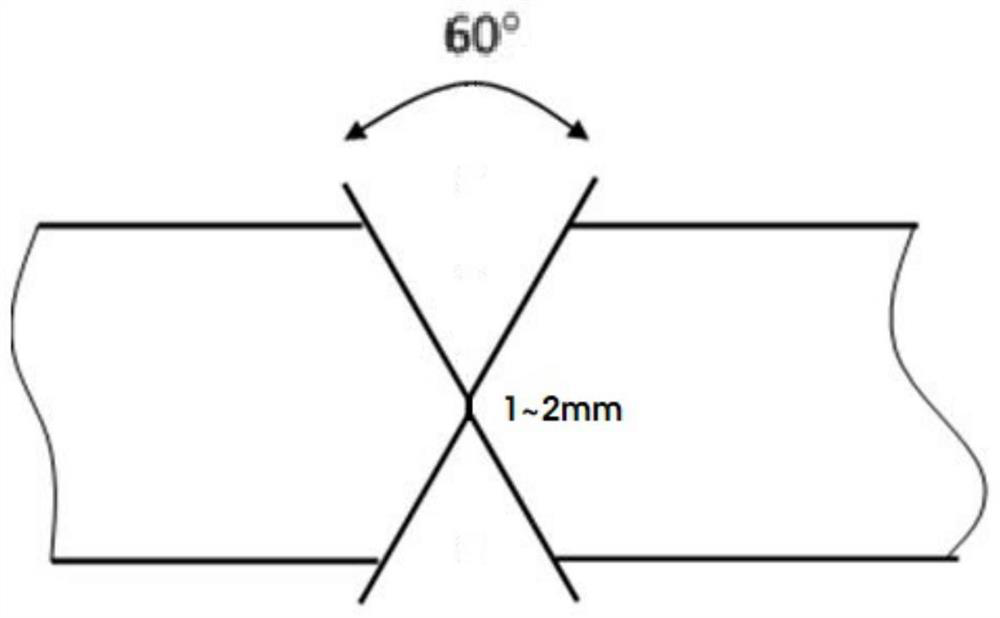

[0061] Example 2: Submerged arc welding is performed on the new low-Mo refractory steel Q420FRE grade steel with a specification of 30 mm, and the welding position is flat welding.

[0062] (1) According to the thickness, such as image 3 For the X-shaped welding groove shown, the groove angle is 30° on one side, and the root is left with a blunt edge of 1-2mm;

[0063] (2) The Q420FRE steel plate mainly uses Harbin Well Welding submerged arc welding wire H460FRΦ4.0 and submerged arc flux SJ18, and in step (4) for back welding, Harbin Weil Welding gas shielded welding wire HS460FRΦ1.2 is used; The matching of welding materials fully meets the requirements of the present invention for welding deposited metal components;

[0064] (3) The steel plate is preheated at 100°C;

[0065] (4) Carry out 3 rounds of bottom welding on the steel plate, using the gas shielded welding method. The first welding current is 210~230A, the welding voltage is 23~25V, the welding speed is 23~25cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com