Large sheet metal part limiting bending tool

A sheet metal part and bending technology, applied in the field of limit bending tooling of large sheet metal parts, can solve the problems of low safety factor, time-consuming and laborious processing, etc., and achieve the effect of reducing labor force, improving safety factor, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

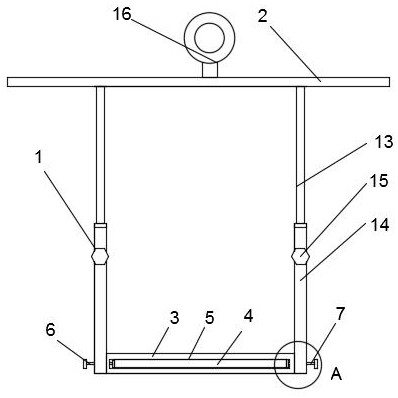

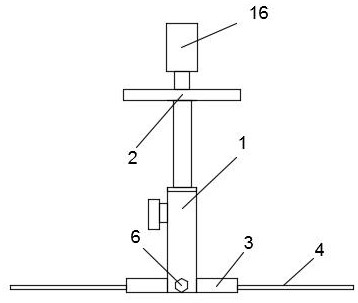

[0018]Such asfigure 1 It is a schematic structural diagram of the present invention, a large sheet metal limit bending tool, including a bracket 1, and the upper end of the bracket 1 fixes a beam connecting rod 2, the bracket 1 fixedly connected to the support guide frame 3, the support orientation The interior of the frame 3 is opened in a cross-shaped hole 5 for the sheet metal body 4, the support guide frame 3, and the support guide frame 1 is inserted with the left limit piece 6 and the right limiting member 7.

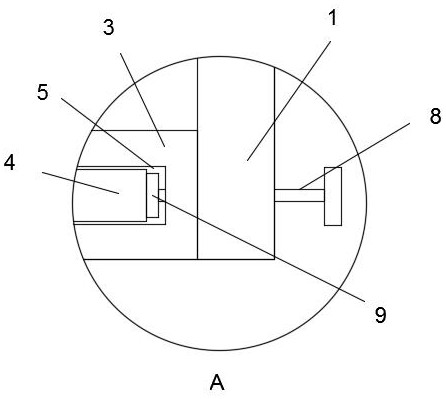

[0019]CombineFigure 1 to Figure 3As shown, the left limit piece 6 and the right limiting member 7 are the same, and each is formed by the bolt 8 and the push plate 9, the bolt 8 passes through the bracket 1 and inserted into the piercing hole 5 of the support guide frame 3, The front end of the bolt 8 is connected to the push plate 9.

[0020]Combineimage 3 withFigure 4 As shown, the push plate 9 is opened with a slot 10 for the bolt 8 insertion, and the finisher plate 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com