Preparation method of super-hydrophilic anti-fouling antibacterial separation membrane for efficiently separating oil-water emulsion

A technology for separating oil and water and emulsion, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve problems such as hindering the wide application of membrane technology, improve antifouling and antibacterial properties, shorten reaction time, and improve hydrophilicity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

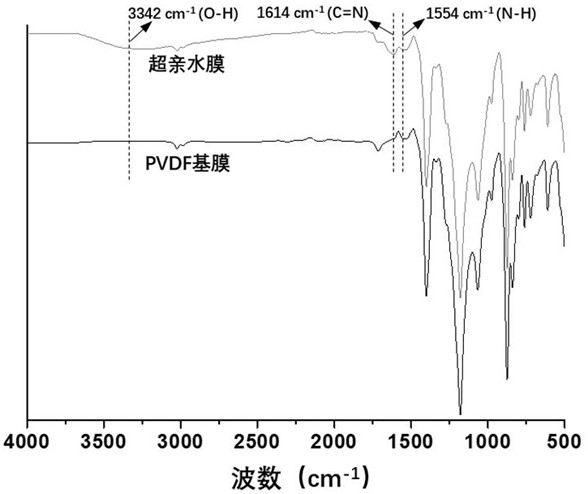

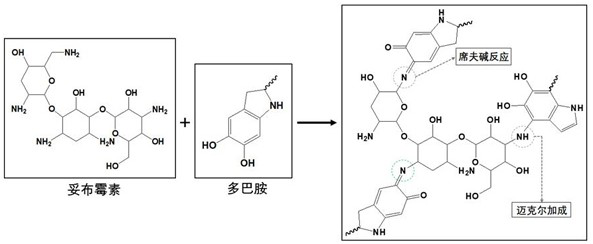

[0028] A method for preparing a super-hydrophilic antifouling and antibacterial separation membrane for efficiently separating oil-water emulsions, comprising the following steps:

[0029] 1) Add tobramycin and ammonium persulfate to the dissolved Tris-HCl buffer solution (pH=8.5), shake and oscillate evenly, add dopamine hydrochloride, and obtain the mixed solution a after ultrasonic dissolution; the mixed solution a The concentration of tobramycin in the medium is 2.2×10 -2 mol / L, the concentration of ammonium persulfate is 2.8×10 -2 mol / L, the concentration of dopamine hydrochloride is 1.1×10 -2 mol / L.

[0030] 2) Put the PVDF porous base membrane in the mold, slowly pour the mixed solution a into the mold, fix the mold in a constant temperature oscillation box at 25 °C for reaction, take it out after 0.25 h of reaction, and rinse it several times with deionized water , until the residual liquid on the membrane is washed, and the super-hydrophilic, antifouling and ant...

Embodiment 2

[0033] A method for preparing a super-hydrophilic antifouling and antibacterial separation membrane for efficiently separating oil-water emulsions, comprising the following steps:

[0034] 1) Add tobramycin and CuSO to dissolved Tris-HCl buffer (pH=8.5) 4 / H 2 o 2 After shaking and oscillating evenly, add dopamine hydrochloride, and after ultrasonic dissolution is complete, a mixed solution a can be obtained; the concentration of tobramycin in the mixed solution a is 1.1×10 -2 mol / L, CuSO 4 / H 2 o 2 The concentration is 1.1×10 -2 mol / L, the concentration of dopamine hydrochloride is 1.1×10 -2 mol / L.

[0035]2) Put the PVDF porous base membrane in the mold, slowly pour the mixed liquid a into the mold, fix the mold in a constant temperature oscillation box at 20 °C for reaction, take it out after 0.5 h of reaction, and rinse it with deionized water several times , until the residual liquid on the membrane is washed, and the super-hydrophilic, antifouling and antibact...

Embodiment 3

[0038] A method for preparing a super-hydrophilic antifouling and antibacterial separation membrane for efficiently separating oil-water emulsions, comprising the following steps:

[0039] 1) Add tobramycin and sodium periodate to the dissolved Tris-HCl buffer solution (pH=8.5), shake and oscillate evenly, then add dopamine hydrochloride, and after ultrasonic dissolution is complete, the mixture a can be obtained; the mixture a The concentration of tobramycin in the medium is 4.4×10 -2 mol / L, the concentration of sodium periodate is 5.8×10 -3 mol / L, the concentration of dopamine hydrochloride is 1.1×10 -2 mol / L.

[0040] 2) Put the PVDF porous base membrane in the mold, slowly pour the mixed solution a into the mold, fix the mold in a constant temperature oscillation box at 25 °C for reaction, take it out after 1 hour of reaction, and rinse it several times with deionized water , until the residual liquid on the membrane is washed, and the super-hydrophilic, antifouling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com