Infrared stealth film for radar antenna and preparation method thereof

A radar antenna and film technology, applied in the field of infrared stealth film and its preparation, can solve the problems of large heat accumulation, unsuitable radar antenna, and limited stealth effect, so as to enhance infrared stealth performance, realize effective stealth and timely heat dissipation, and improve The effect of battlefield survival probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

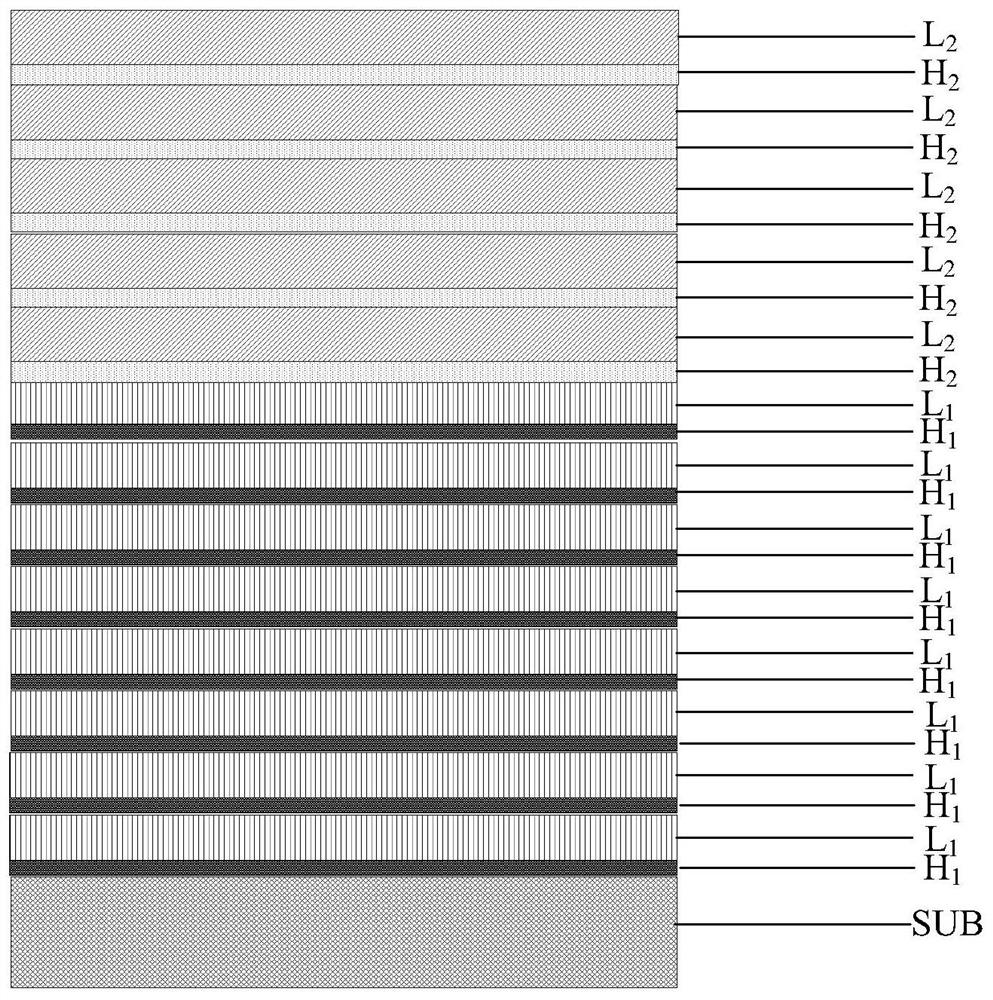

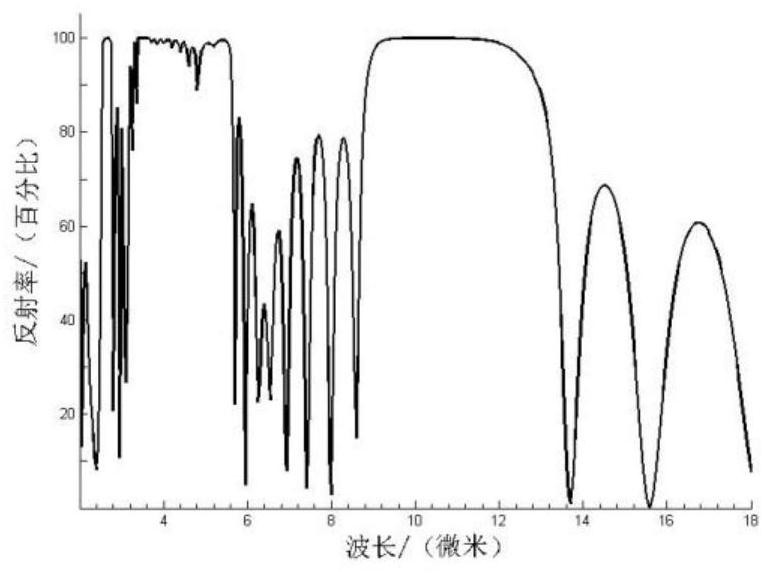

[0018] Such as Figure 1-4 As shown, the infrared stealth film used for radar antennas in this embodiment has a multilayer film structure, and the multilayer film structure includes a substrate, and high refractive index materials alternately stacked on the substrate from the inside to the outside. layer and low refractive index material layer, the specific arrangement is:

[0019] SUB|(H 1 L 1 ) m (H 2 L 2 ) n |AIR,

[0020] Among them, SUB is the base, AIR means air, and H 1 、H 2 Indicates two thicknesses of high-refractive index material, L 1 , L 2 Indicates two thicknesses of low-refractive index materials, each layer has a specific physical thickness, m and n represent the number of layers; H 1 The thickness is 200~500nm, H 2 The thickness is 400~600nm, L 1 The thickness is 900~1200nm, L 2 The thickness is 1200-1500nm, m is 4-8, and n is 3-7.

[0021] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com